Building a soakaway in clay soil can be challenging due to the low water infiltration rates achieved in most clayey soils. Some clay soils will achieve virtually zero infiltration and in these soils a soakaway will not be practical.

Other clay soils will achieve a low infiltration rate which makes a rainwater soakaway in clay possible. However, in these soils a conventional soakaway pit is often only effective when it is built very deep to increase the infiltration surface and includes a large storage area to store water while it slowly soaks away. Soakaway crates in clay have the advantage of a large void space which can be advantageous in such conditions. Even in these cases the soakaway can struggle to comply with time of emptying requirements due to the low infiltration rate.

Soakaway Design in Clay Soils

Where a low infiltration rate is expected such as in clay soils it is critical that a thorough site investigation and infiltration testing is done before the detailed design of any soakaways. A site investigation may reveal better infiltration layers either in another part of the site or in strata beneath the clay layers. In this case sometimes a deep bore soakaway can be installed through the clay layer into the infiltration strata.

One advantage of soakaways in clay soils is that the small pores are less likely to become clogged with sediments which build up within the soakaway. This can make soakaways built in clay soils more robust than some other soils.

How to Build a Soakaway in Clay Soil

Digging a soakaway in clay soil can be approached in the same way as in any other soil, as described here. Particular care should be taken to ensure that the excavation does not become smeared when using mechanical diggers. If smearing does take place the sides of the excavation should be roughened using hand tools.

Other Ground Conditions

The installation of a new soakaway can have significant effects on the surrounding soils. For this reason it is important that the existing ground conditions are assessed before the detailed design of a new soakaway is completed. Below is a summary of some of the most common issues;

Poorly Consolidated Soils

The installation of a new soakaway can cause instability in poorly consolidated soils. This is because the new source of water infiltrating through the soils can lead to wash out of fine materials from the soil. This can lead to significant voids forming over time which are then prone to collapse. In some soils the infiltrating water can also cause the soil to consolidate leading to settlement.

Fill Materials

Infiltrating water passing through loosely compacted fill materials can cause the fill to compact, leading to differential settlement. This is particularly significant in deep layers of fill material, such as infilled quarries or landfill sites. In some cases the fill layers can be protected from infiltration using impermeable liners.

Shrinkable or Expansive Clays

Some types of clay soils can shrink or expand depending on the water content of the soil. A new soakaway will have localized effects on the water content of the surrounding soils which can lead to shrinkage and differential settlement of some clays.

Weakening of Soils

Some types of soils can become weakened when saturated with water. In some cases any increase in the pore water pressure can reduce the effective stresses reducing the shear strength of the soil. If a new soakaway leads to saturation of these layers the soils can be weakened leading to instability and differential settlement of the soils. This can be particularly significant near to slopes and building foundations.

Dissolvable Rocks and Soils

Some calcareous rock formations such as chalk can slowly dissolve over time leading to instability.

Chemical Reactions

Other chemical reactions can take place between some soils and infiltrating water. This includes when anhydride changes to gypsum which results in expansion. Some minerals such as pyrite can also react with water leading to unwanted effects.

Mining Areas

Care should be taken in areas of mining activity that there are no underground shafts or features which may be affected by the infiltrating water. Any possible future subsidence should also be considered.

Mitigation

The effects on potentially unstable ground is likely to be greater for larger, deeper soakaways handling large volumes of runoff, rather than smaller shallower soakaways handling smaller quantities of runoff.

In some cases it may be necessary to protect certain areas of ground with impermeable liners or concrete barriers to prevent water from infiltrating into certain strata.

If there is any doubt as to the suitability of any surrounding soils or geotechnical features, a suitable qualified geotechnical engineer should always be consulted.

Related Spreadsheets from CivilWeb;

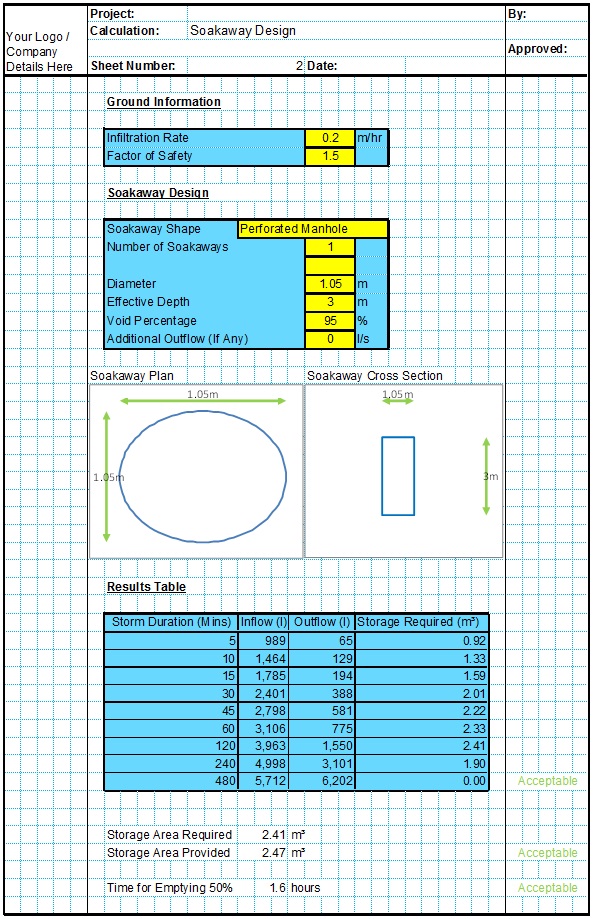

Soakaway Design Spreadsheet

This spreadsheet calculates the requirements for a soakaway system and assists the user to design a suitable system.

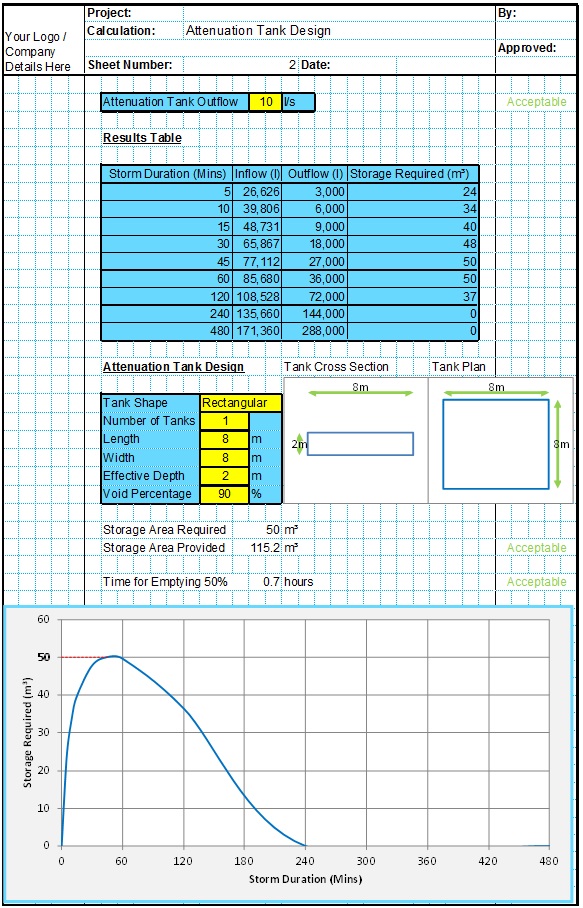

Attenuation Design Spreadsheet

This spreadsheet calculates the requirements for a attenuation system and assists the user to design a suitable system.

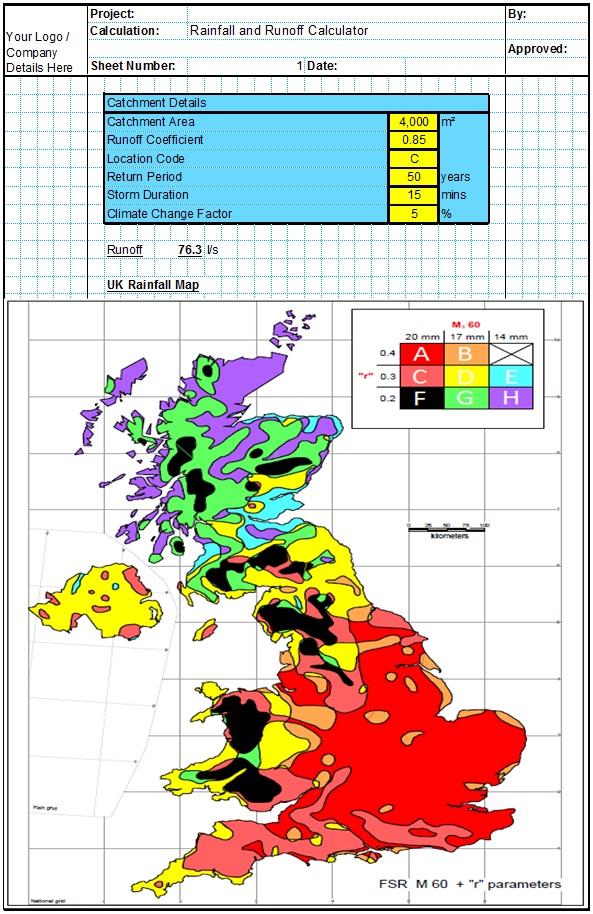

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 7 spreadsheets;

- Colebrook White Pipe Design

- Manning Pipe Design

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design