Concrete pipe design is different from plastic or steel pipe design because concrete pipes behave in a different manner to flexible pipes. Concrete or other rigid pipes will deflect very little during loading which prevents any lateral pressures being developed in the surrounding soils leading to no lateral support. The load is instead taken by the pipe through bending moments which develop in the pipe walls, resisted by the tensile strength of the pipe material. Concrete pipes also attract increased loads from the backfill compared with a flexible pipe.

In the UK pipes made from concrete (both unreinforced and reinforced) and clay pipes are considered as rigid. These pipe materials have their own design procedure outlined below which takes account of the increased backfill loads. Pipes are generally defined as rigid when they are likely to fracture under small deformations, so this often includes asbestos-cement pipes and grey cast iron pipes as well as concrete and clay. In reality the definition is always a judgement as the flexibility of the system will vary based on pipe material, pipe diameter and bedding material.

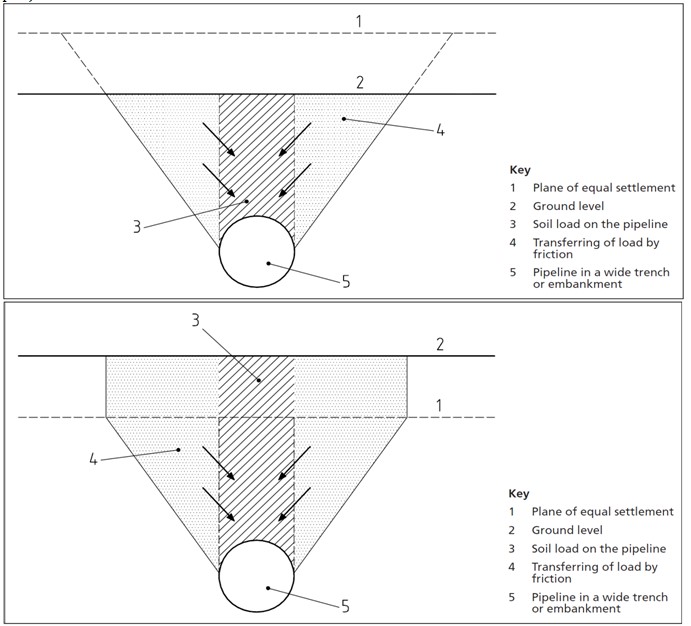

As the concrete pipe is much stiffer than the surrounding soils, the soils around the sides of the pipe tend to settle more than the soils on top of the pipe. This transfers an increased load through friction which acts on the pipe. Concrete pipes can also settle into their bedding material. Over time these conditions tend to dissipate, so the worst case loading for a concrete pipe is often when it is newly installed.

The design procedures detailed below calculate the following loads;

- Backfill load of soil acting on the pipe

- Surcharge loads acting on the pipe from concentrated loads such as traffic loads

- Surcharge loads from small uniformly distributed areas such as those from pad foundations

- Surcharge loads acting from uniformly distributed loads of large extent such as material storage or changes in ground level

- Internal water loads from the water within the pipe

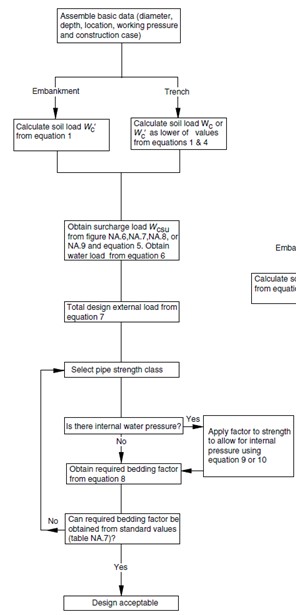

These loads are then compared with the strength of the pipe/bedding system. A flowchart showing the general design procedure for concrete and other rigid pipes is shown below.

Geostatic Backfill Loadings on Concrete Pipes

The soil which is used to backfill around and over the top of the pipe will exert a load on the concrete pipe simply through its weight. How much of this load is able to act on the concrete pipe itself depends on the conditions in which the pipe was installed.

Types of Installation

There are two main conditions of installation which affect how much backfill load the concrete pipe will need to resist. These are detailed below;

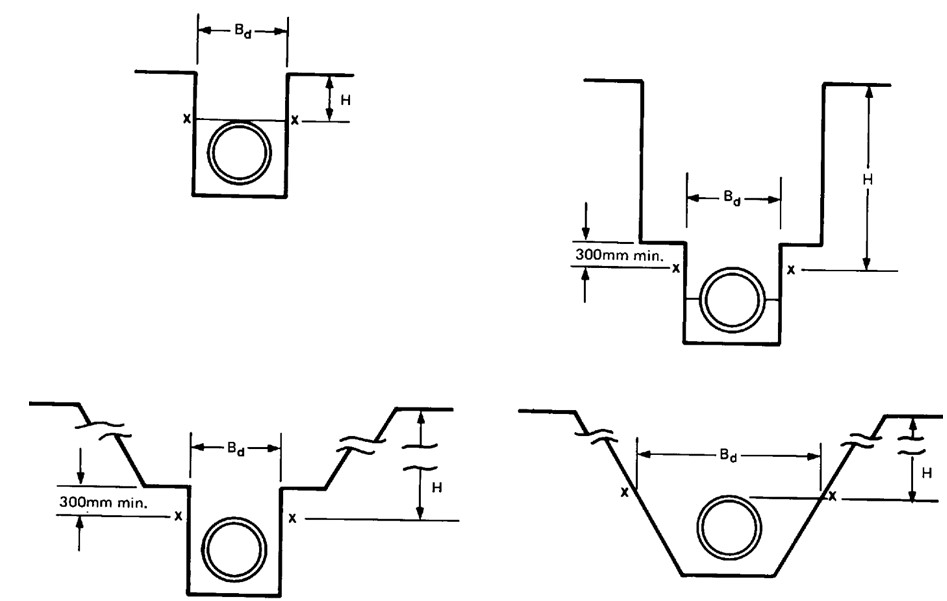

- Narrow Trench – The concrete pipe is installed in a trench installed into the existing ground not much wider than the diameter of the pipe. Various Narrow Trench conditions are shown in the illustration below. Minimum trench widths must be observed.

When a concrete pipe is installed in a narrow trench frictional forces are created between the backfill material and the trench walls which act upwards and reduce the effective geostatic load acting on the pipe. These frictional forces effectively increase as the depth of the trench increases, reducing the proportion of the backfill load acting on the pipe. For this reason a clayey soil will exert more pressure on the pipe than a sandy soil in narrow trench conditions because the internal angle of friction is lower in clayey soils.

If the trench depth reaches a value around 10 times the trench width, the load will barely increase at all with any further increase in fill depth as the soil will start to arch over the concrete pipe.

- Wide Trench or Embankment (Positive Projection) – The pipe is installed in a wide trench or on the ground and an embankment installed over the top. This is termed the positive projection condition and can either be Complete Projection or Incomplete Projection. Various Wide Trench conditions are shown in the illustration below. In wide trench installation conditions the frictional forces act downwards and now effectively increase the load acting on the pipe. This is because the concrete pipe is much stiffer than the surrounding material which means that the adjacent columns of soil are settling more than the column directly above the pipe. In this case sandy soils exert a greater pressure on the concrete pipe due to their higher angle of internal friction than clayey soils in the wide trench condition.

It is not always obvious which condition will be critical at the early stages of concrete pipe design. Even if the pipe is to be installed in a trench the minimum trench widths and requirements for working space around the concrete pipe and the minimum slope of the surrounding excavations may turn this into a wide trench condition. However many of the inputs required to calculate the different loads are the same and therefore it is recommended that the designer calculate the loads for narrow trench and wide trench/embankment conditions. Then the critical condition is the lowest of the two values. The CivilWeb Buried Pipe Design spreadsheet makes this easy by automatically calculating both design conditions and detailing which condition is critical.

In every design case there is a critical trench width below which the narrow trench condition is critical and above which the wide trench conditions are critical. This width is called the transition width and it is useful for the designer to know this value as it shows when an increase in the trench width will increase the load on the pipe (narrow trench conditions) or not (wide trench conditions). The CivilWeb Buried Pipe Design spreadsheet shows the designer where the transition width is by plotting the values of all three design conditions on a graph. Where the narrow trench condition values cross the lowest wide trench value is the transition width. An example of a similar graph taken from BS 9295 is shown below. A similar effect can be seen when a trench of a certain width can be installed at different depths. In this case there is a transition depth below which wide trench conditions are critical and above which narrow trench conditions are critical. This is also shown below.

Geostatic Backfill Load on Concrete Pipes Calculation – Narrow Trench

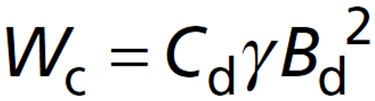

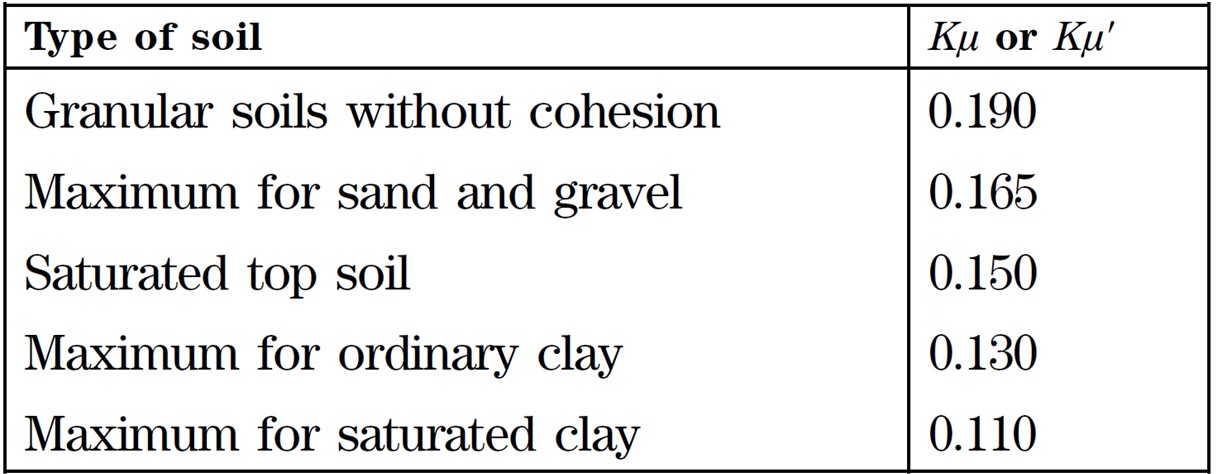

The backfill load (Wc) created by narrow trench conditions can be calculated using the below equation. This equation combines the downward forces of the soil column and the upward forces of the friction between the soil column and the trench walls.

Soil Unit Weight (γ)

The soil unit weight is simply the density of the backfill material. If this is known this value can be input directly. For general purposes a value of 19.6kN/m3 is often used relating to a soil material with a density of around 2,000kg/m3. If a lower value is used this must be justifiable in that it is certain to occur consistently and over a large proportion of the pipe.

Effective Width of the Trench (Bd)

The effective width of the trench being considered is the width of the trench at the top of the pipe as shown in the diagrams below. This is calculated in the CivilWeb Buried Pipe Design spreadsheet using the width of the base of the trench and the average slope of the excavation sides as a percentage. Note that minimum trench widths must be observed.

Narrow Trench Fill Load Coefficient (Cd)

The equation for backfill loads in narrow trenches is completed by the narrow trench fill load coefficient, which can be calculated using the below equations.

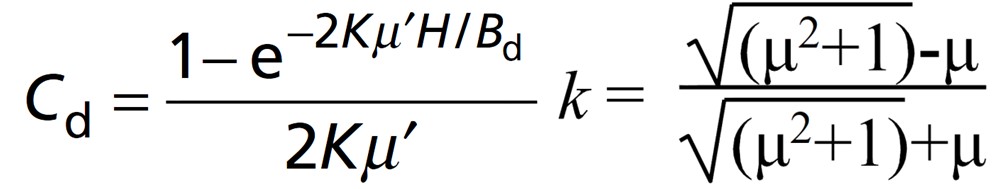

Rankine’s Coefficient (k) & Coefficient of Backfill/Trench Sliding Friction (μ’)

Rankine’s Coefficient k is the ratio of active lateral pressure to vertical pressure. The Coefficient of Backfill/Trench Sliding Friction μ’ describes the friction between the backfill and the material making up the trench walls. These soil parameters can be determined from laboratory testing of the soils or can be estimated from generalized parameters.

A calculator tool is included with the CivilWeb Buried Pipe Design spreadsheet which calculates the k and kμ values from μ.

However it is common to take the values of k and μ’ together and treat them as an empirical function of the soil properties as it is unlikely that the individual values will be known in advance of the laying of drainage pipes. There is guidance in BS EN 1295-1 on values for kμ and kμ’ for typical soil types. Note for unknown soil conditions a kμ’ value of 0.13 is commonly used (low values increase loads in narrow trench conditions). The CivilWeb Buried Pipe Design spreadsheet allows the designer either to specify a soil type, or input kμ’ directly.

Height of Backfill (H)

The height of the backfill on top of the pipe is used to determine the loads from the column of soil above the pipe. In a narrow trench this is typically the depth from the ground surface to the top of the pipe. An illustration below shows H along with the other parameters used to calculate the backfill load in a narrow trench.

Late Removal of Trench Sheets

It should be noted that the narrow trench condition calculations require the frictional forces between the trench walls and the backfill to be mobilized. If trench supports such as close boarded sheet piles are not removed before the trench is backfilled and compacted this will prevent the frictional forces from becoming mobilized.

In some cases this may be unavoidable due to safety and ground stability concerns. Therefore in these conditions the backfill load is equal to the total weight of the trench backfill, as shown in the following equation;

Conclusion

Typically the narrow trench backfill load has been taken from various charts and tables of values computed from typical soils and trench geometries. The CivilWeb Buried Pipe Design spreadsheet allows the designer to calculate the narrow trench backfill load from more detailed information if required and does not require interpolation of tabulated values or estimation from a graph. In most cases however the use of typical vales are justified, particularly for soil properties which are usually unknown at the time the design is undertaken.

Geostatic Backfill Load on Concrete Pipes Calculations – Wide Trench or Embankment (Positive Projection)

The geostatic backfill loads from wide trench or embankment conditions act in a different manner to the narrow trench condition as described previously. In this case the frictional forces acting in the fill are adding to the load of the column of soil above the pipe.

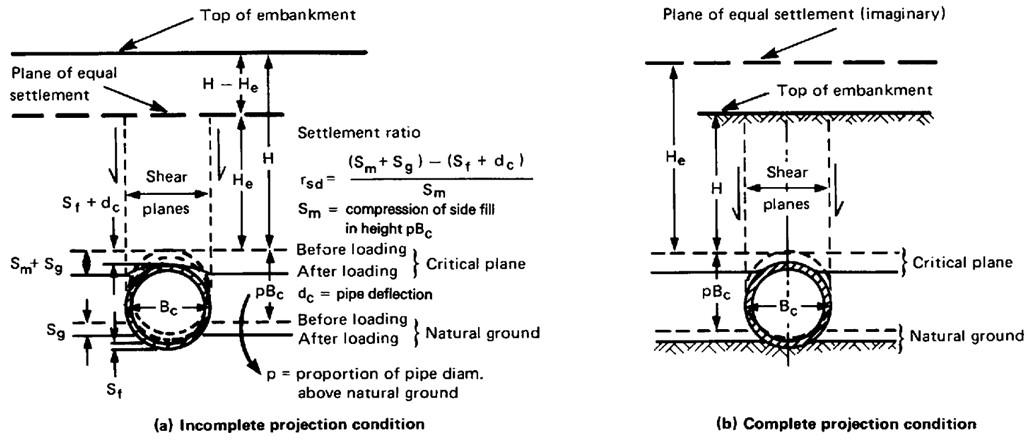

There are two types of wide trench or embankment with positive projection conditions, complete projection and incomplete projection. The complete projection condition assumes that the fill above the concrete pipe is relatively shallow so the frictional slip planes extend all the way to the surface of the fill. The incomplete projection condition assumes that the frictional slip planes stop within the fill at the plane of equal settlement.

The complete and incomplete design conditions are calculated in different ways and the critical design case is the lower of the two calculations. This depends on whether the plane of equal settlement is within the depth of fill or not, as illustrated in the below diagrams taken from BS 9295 with complete projection on top and incomplete projection at the bottom.

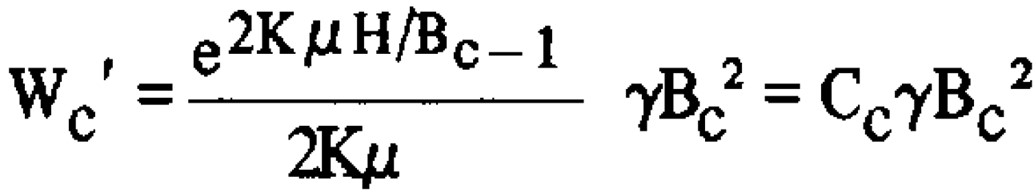

Backfill Load – Complete Projection

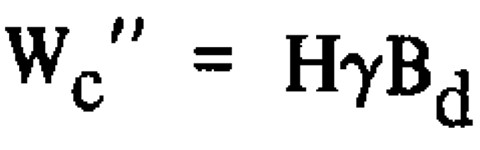

The backfill load for the complete projection condition can be calculated using the below equation;

Rankine’s Coefficient (k) & Coefficient of Backfill/Trench Sliding Friction (μ)

As described in the previous section these soil parameters are typically treated as a single empirical value. Note while μ and μ’ are usually the same for any particular soil, they are often given different design values for unknown soil conditions as μ’ has a positive effect on the loading and μ has a negative effect. Therefore low values of μ’ and high values of μ are often used even though this is practically impossible.

Soil Unit Weight (γ)

As described in the previous section.

Height of Backfill (H)

The height of the fill is the height between the top of the fill and the top of the pipe.

Outside Diameter of the Pipe (Bc)

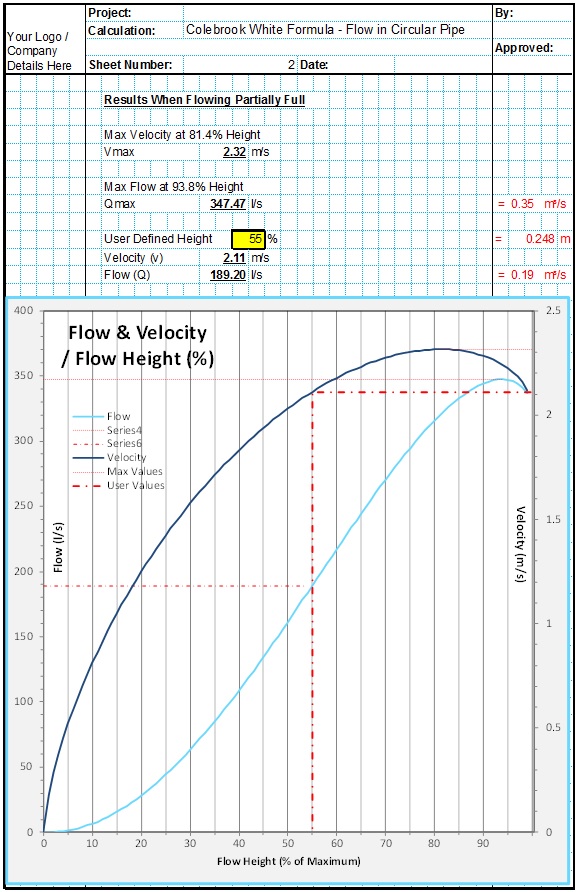

The outside diameter of the pipe dictates the width of the column of soil acting on the pipe. The diameter of the pipe is usually determined during pipe flow calculations. The exact outside diameter of the pipe is often unknown at the time of design, however it can be estimated from the nominal diameter based on manufacturer’s information. Note that if a concrete cradle or protective arch is used (bedding class A) the total width of the concrete should be used for design in place of the outside diameter of the pipe.

Backfill Load – Incomplete Projection

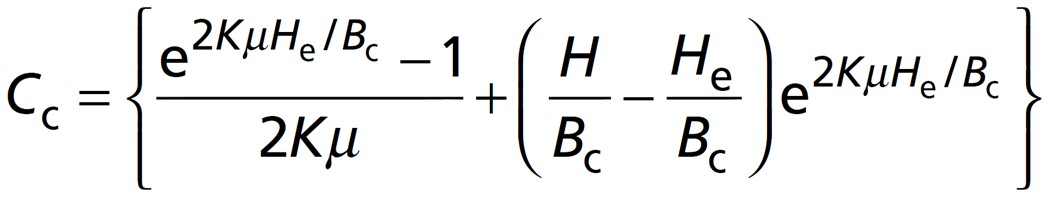

The backfill load for the incomplete projection condition is similar to the above but with a different Cc coefficient, which can be calculated using the below equation;

Height of Plane of Equal Settlement (He)

The height of the plane of equal settlement is used to determine the backfill load for the incomplete projection case where the frictional slip planes cease to add to the backfill load within the depth of the backfill material. The location of the plane of equal settlement therefore determines which condition is present and therefore which calculation is critical.

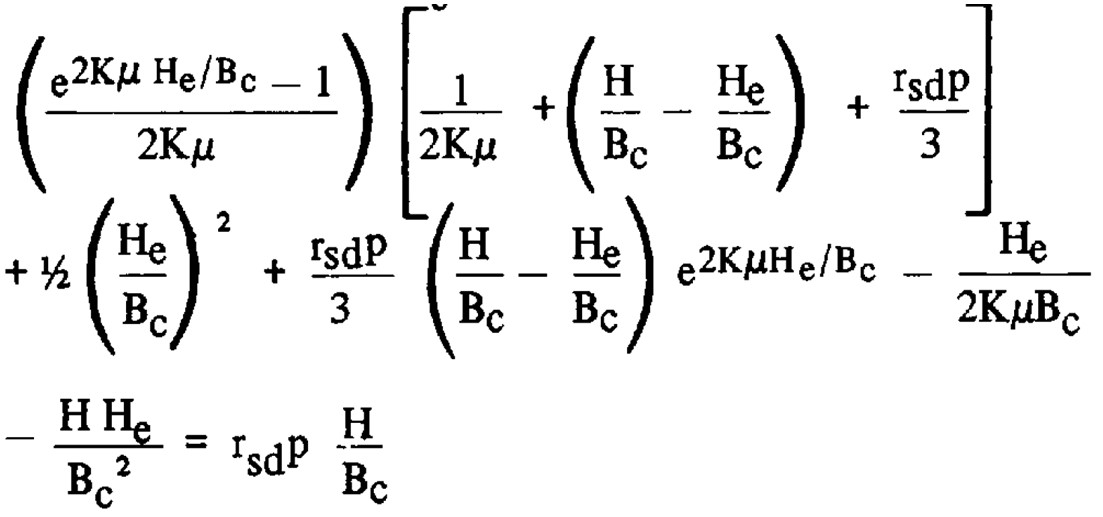

Determining the plane of equal settlement is however not a straightforward calculation to make and includes a number of semi-empirical coefficient choices which affect the outcome. It can be calculated directly using an iterative solution to the below complex equation. A tool is included within the CivilWeb Buried Pipe Design spreadsheet which will calculate He directly.

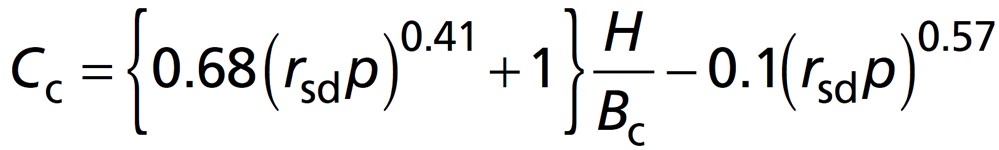

However as the above is so difficult to solve by hand a number of general solutions for typical soil parameters and concrete pipe sizes have been developed and these are used much more commonly than the full equation above. Charts have been developed to estimate values for both Cc or Wc for typical conditions.

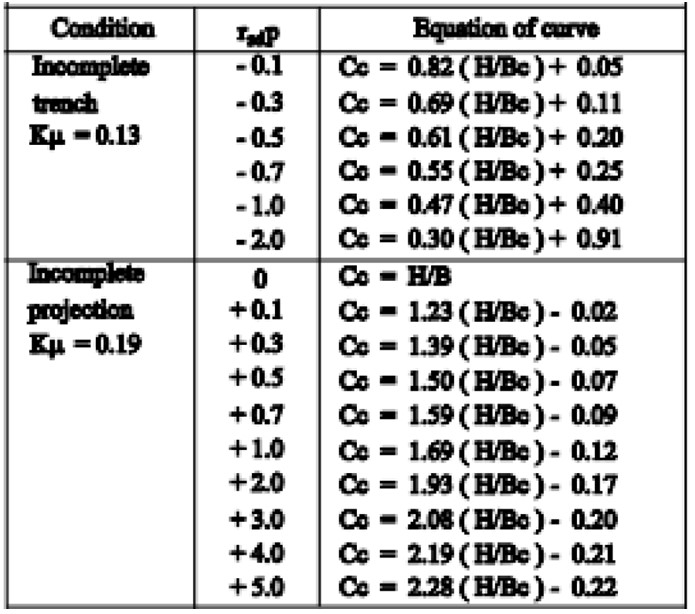

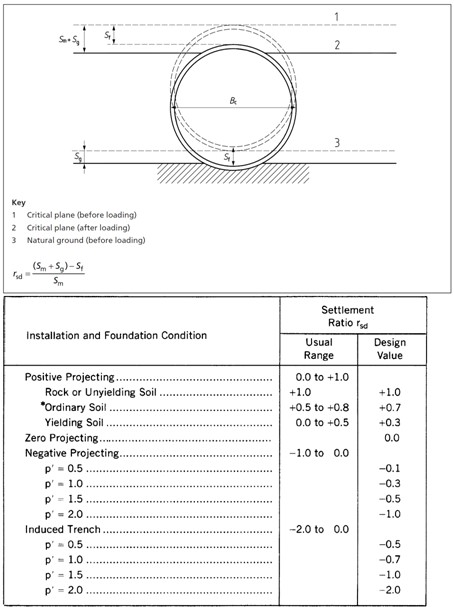

Another solution is presented in BS EN 1295-1 as a series of equations which can be used for most design situations, shown below.

While these equations cover most design situations, for unusual situations where a precise value is required interpolation between different equations is inaccurate. A further approximate design equation was proposed within BS 9295 as shown below. While the errors for the approximate equation are between -1.4% and 2.8% for relevant conditions, a table was also issued showing the error allowing the equation to be adjusted. This method is used in the CivilWeb Buried Pipe Design spreadsheet to determine the value of Cc with the equation results adjusted by interpolation of the below error table.

Settlement Deflection Ratio (rsd) and Projection Ratio (p)

To determine the plane of equal settlement requires determining two further factors, the settlement deflection ratio (rsd) and the projection ratio (p).

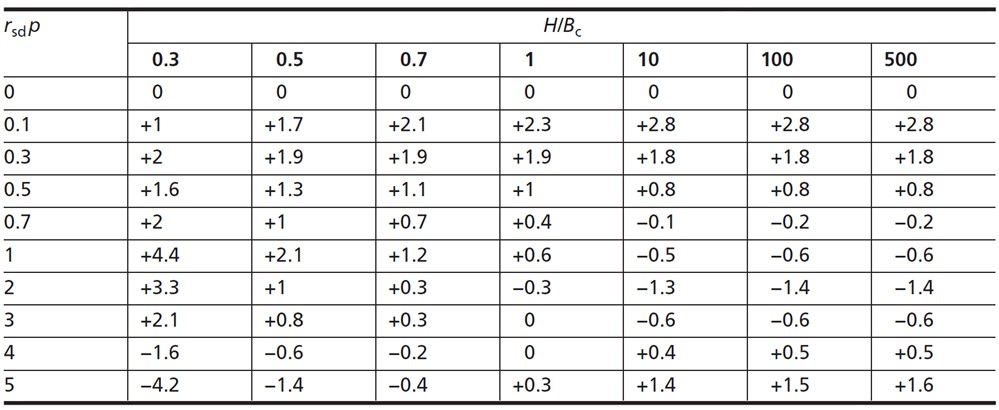

The settlement deflection ratio value describes the ratio between the settlement of the fill and the settlement of the ground underlying the pipe, as shown in the below equation and diagram taken from BS 9295.

It is highly unlikely that this effect will be measured onsite before a drainage pipe is laid. The ratio varies typically between 0 and 1.0 with 0 being very soft soils and 1.0 being rock. The ratio can be negative in some cases as shown in the table below. The value of the settlement deflection ratio depends on the degree of compaction achieved in the fill material to the sides of the pipe. With good construction practices a value of 0.7 is recommended for normal soils. This need only be amended for pipes bearing on rock or on particularly weak or compressible soils.

The projection ratio (p) is the proportion of the pipe outer diameter which is above the bedding level or the natural ground level. While this value could be measured onsite, use of standard bedding types allows the designer to determine a suitable projection ratio value for design. Bedding types D, F and N have a value of 1.0. Bedding types B and S have a value of 0.7.

In practice the values for the settlement deflection ratio and the projection ratio are often taken together as 0.7 for bedding types D, F and N and 0.5 for bedding types B and S. The CivilWeb Buried Pipe Design spreadsheet assumes a standard value based on the chosen bedding type though the designer can override these values if required.

Crushing Strength of Concrete Pipe

After all the loadings on the pipe have been determined as per the above sections, next the concrete pipe must be checked for adequate strength. While the loads acting on the pipe induce bending moments in the pipe ring it has become accepted practice to use the crushing strength of the pipe determined from a three edge crushing test instead of calculating the bending moments and bending resistance of the ring.

The concrete pipe crushing strength is not the only factor affecting the strength of the overall concrete pipe system. The bedding type has a significant impact as it has been demonstrated that the load carrying capacity of the concrete pipe is increased by the bedding by different amounts depending on the bedding type. This is also where the factor of safety is included in the design method. So the total allowable crushing load on the concrete pipe is determined by the pipe crushing strength multiplied by the bedding factor and divided by the factor of safety.

Concrete Pipe Crushing Strength

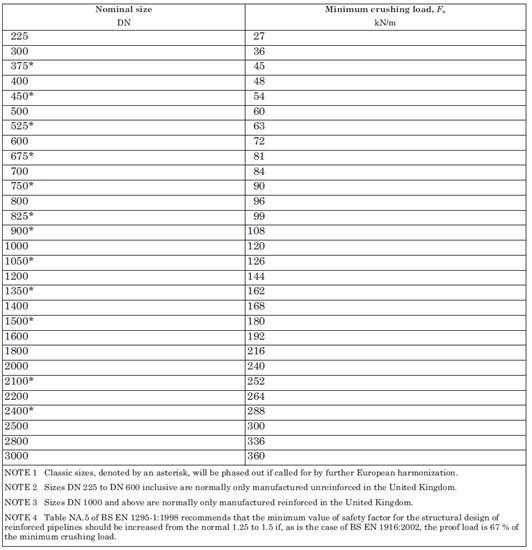

In the UK the minimum crushing load is usually specified as a multiple of the nominal pipe diameter. The most commonly specified strength class is 120, so the crushing strength in kN/m will be 120 times the nominal pipe diameter in metres. The CivilWeb Buried Pipe Design spreadsheet defaults to allow a class 120 pipe though this input can be overridden by the designer if required. A table taken from BS 5911 showing the crushing values for 120 strength class pipes of standard sizes is shown below.

Factor of Safety

This design method incorporates a global factor of safety which is applied to the crushing strength of the concrete pipe being considered. The following factors are considered when choosing an appropriate factor of safety;

- Crushing Strength of the Concrete Pipe - It is considered unlikely that the strength of concrete pipes manufactured in accordance with the relevant standards will drop significantly below the stated crushing strength.

- Bedding Factor – Similarly with suitable supervision a reputable contractor should be able to achieve the stated bedding factor in the vast majority of cases. Experimental data suggests that the bedding factors stated in standards are conservative.

- Loading Equations – The loading equations tend to be slightly conservative, particularly where soil material properties are common but unknown.

- Durability – Foul sewer pipes or pipes laid in aggressive ground may warrant a larger factor of safety if there are any risks that the pipe may deteriorate faster than generally expected due to chemical attack from either the ground or from effluent in the pipe.

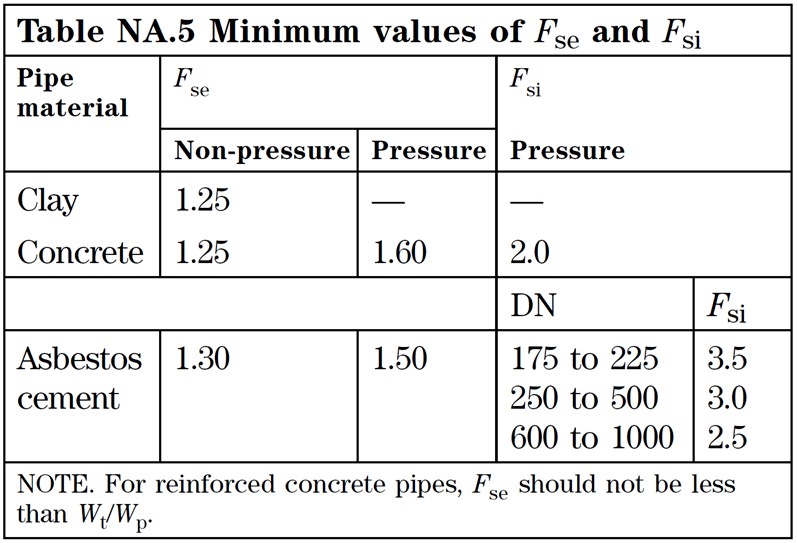

The factors of safety typically employed in this method are quite low. A value of 1.25 was commonly used where the concrete pipe proof load was high at 80% as per the old British Standard. However the new European Standard BS EN 1916 uses a value of 67% of the ultimate load for reinforced pipes. It is felt that this increases the risk of poor quality concrete pipes being used onsite, therefore a factor of safety of 1.50 is sometimes used for reinforced pipes. BS EN 1295-1-1997 advised a value of 1.25 for general use but a value of 1.5 for reinforced pipes with a 67% proof load, as shown in the below table.

The 2019 version of the same standard removed a specific recommended value and left the designer to use their judgement based on the perceived risks of overloading and material and workmanship quality. Generally a conservative approach is to use a factor of safety of 1.25 for unreinforced pipes and 1.5 for reinforced pipes. Whether the pipe will be reinforced or unreinforced depends on the manufacturer, but generally pipes below 600mm nominal diameter are unreinforced, and larger pipes are reinforced. However some manufacturer’s in the UK continue to test their reinforced pipes to 80% proof load as per the old BS 5911-100 standard, allowing a factor of safety of 1.25 to continue to be used.

Concrete Pipe Design - Conclusion

The structural capacity of the concrete pipe and bedding system can now be calculated simply as the concrete pipe crushing strength multiplied by the bedding factor divided by the factor of safety. This capacity is now simply checked against the total of the loads acting on the pipe to determine if the pipe and bedding system proposed is adequate.

Get your copy of the CivilWeb Buried Pipe Design spreadsheet including full concrete pipe design now for only £20.

Or why not bundle the CivilWeb Buried Pipe Design spreadsheet with our Pipe Flow Calculator for only £5 extra?

Or save £50 by buying our full Drainage Design Suite including all our drainage design spreadsheets.

Download Free Trial Version

To try out a fully functional free trail version of this software, please Click Here or enter your email address below to sign up to our newsletter.