French drain filter fabrics are geotextiles installed with french drains both as a separation layer and to prevent fine sediments from infiltrating the filter material and clogging up the drain. A geotextile filter fabric layer at the top of the french drain can both separate the top layer making replacement easier and can act as a filter to improve the water quality of the runoff before it enters the french drain.

Filter fabrics for foundation drainage are specified in much the same way as those for traditional french drain systems. The best filter fabric for french drains depends on type of french drain used, whether any infiltration is required and on the size of sediment particles in the surrounding soils. Some common french drain details include a filter cloth for the perforated pipe. This is not recommended however as the filter fabric often clogs up quite quickly. If the filter cloth is installed around the perforated pipe rather that around the french drain trench, it cannot be replaced without also installing a new perforated pipe.

Impermeable Membranes

Impermeable membranes are also often used in french drains where the infiltration of runoff into the soil needs to be prevented or where infiltration of groundwater into the french drain needs to be prevented. Impermeable membranes are also used in curtain drains to prevent groundwater from passing through the curtain drain.

Fine sediments should be prevented from migrating into the french drain from the surrounding soils. Fine particles will clog up the filter material and can block the drain if they are able to migrate through the filter material. Further information is included in our French Drain Clogged post. Migration of fines can also present stability issues in the surrounding soils. This can be reduced by installing a suitable french drain filter fabric.

Geotextiles are generally produced either as woven, non-woven or knitted materials. The non-woven geotextile types can be further divided into chemically bonded, heat melded or needle punched varieties. Each has its own advantages but generally woven geotextiles contain relatively small numbers of larger openings which makes them more suitable as a simple separation layer. Non-woven geotextiles contain large numbers of smaller openings which makes them more suitable as a filtration layer and for preventing the migration of fines either into or out of the french drain. They also generally have a greater permeability making them more suitable as french drain filter fabrics where permeability is desired. For this reason non-woven geotextiles are usually specified for use in french drains.

French Drain Filter Fabric Testing and Certification

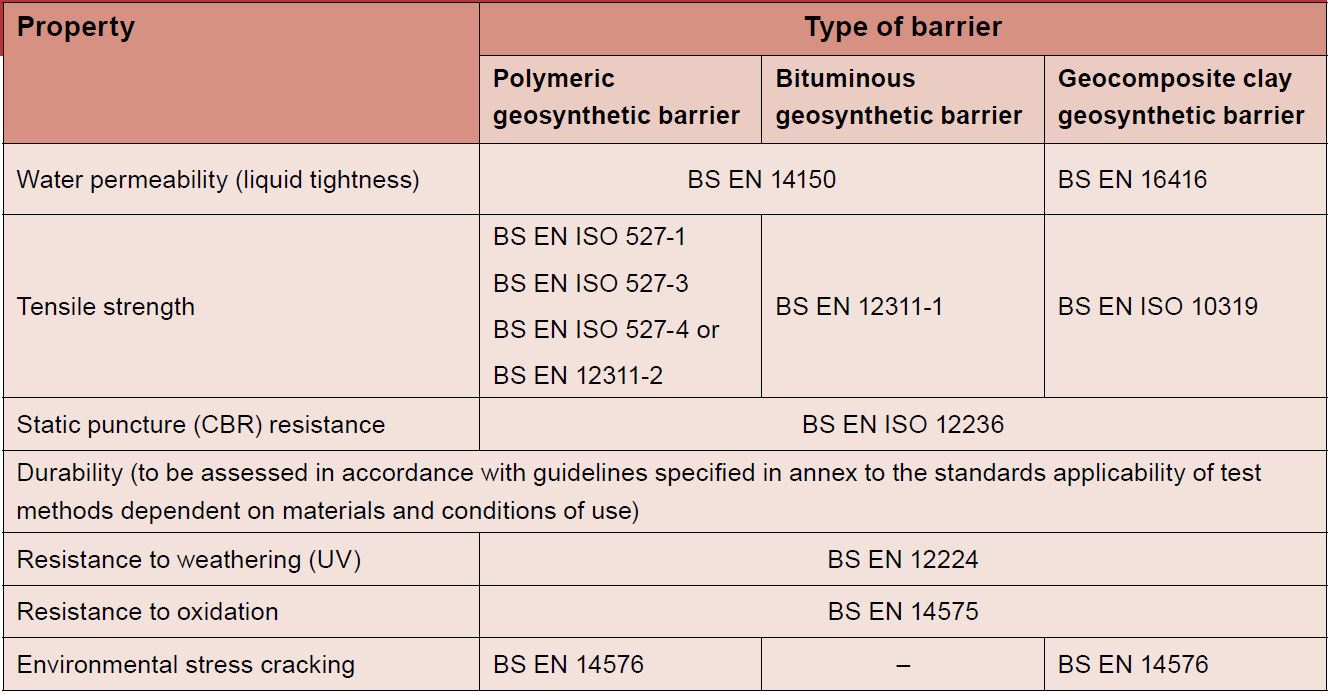

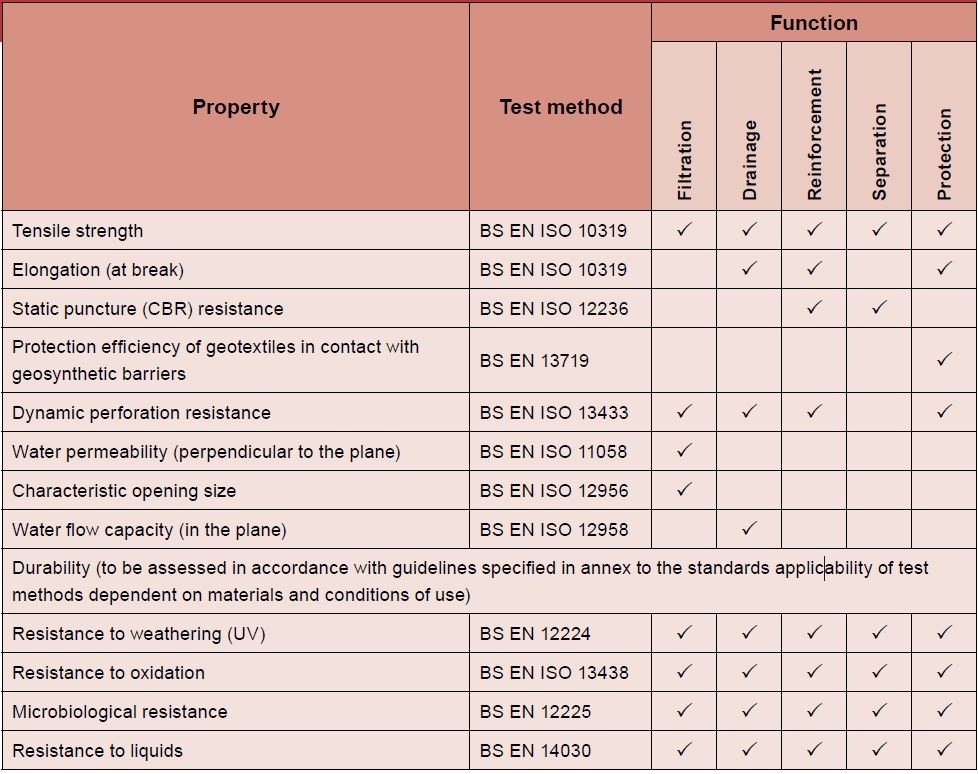

There are a number of standardized product performance tests which are undertaken on geotextiles including french drain filter fabrics to allow designers to compare their performance. These are very neatly summarized in a table in the SUDS Manual, reproduced below. A similar table for geosynthetic barriers is also included below.

Permeable French Drain Filter Fabrics

The following issues should be considered before the correct filter fabric is specified;

- Pore Size – The selected pore size should be sufficient to prevent large amounts of fine materials from the surrounding soils migrating into the french drain. Where infiltration into the surrounding soils is required, the pore size should prevent any sediments present in the runoff from migrating from the french drain and blocking the pores of the surrounding soils. This would have the effect of reducing the infiltration rate into the soils over time.

- Permeability – The filter fabric must be permeable enough to handle the volume of runoff required. The required permeability is determined during the french drain design. Where infiltration into surrounding soils is desired the filter fabric should be at least as permeable as the surrounding soils, otherwise the filter fabric will limit the natural infiltration rate of the soil and restrict the infiltration performance of the french drain.

- Breakthrough Head – Some filter fabrics require a head of water to be present before they become permeable and allow the water to pass through. This can limit the use of some geotextiles at the top layer where they may be installed only 200mm – 300mm below the surface.

- Clogging Resistance – The french drain filter fabric should retain the required sediments without clogging.

- Puncture Resistance – The french drain filter fabric needs to have sufficient resistance to resist the punching stresses caused by the sharp aggregates or tree roots.

- Tensile Strength – The filter fabric must be strong enough to resists any forces from any expected imposed traffic loads.

- Chemical Tolerances – The french drain filter fabric must be resistant to any chemical or microbial effects which are expected from either the natural soils, filter materials or runoff water. Care must also be taken to ensure that the filter fabric does not become exposed to any acids, alkalis or other chemicals which can cause damage to the filter fabric while it is stored onsite.

- UV Tolerance – The french drain filter fabric must be sufficiently resistant to the levels of UV expected, which is typically zero. The UV tolerance must be allowed for when storing the french drain filter fabric onsite to prevent deterioration.

- Tree Root Penetration – A root barrier can be used to protect permeable geotextiles where the french drains enters a root zone. This should not be an issue for well installed impermeable barriers.

Special geotextiles can also sometimes be specified as french drain filter fabrics to prevent contaminants such as contaminated sediments or hydrocarbons in the runoff from infiltrating into the ground.

Filter Fabrics for Filtration

Where fine geotextiles are used for filtration they should be carefully detailed to allow easy replacement as they are likely to become clogged with sediments quite quickly. Inspection and maintenance schedules need to be fairly frequent and reliable as the french drain will fail to function when this layer becomes clogged.

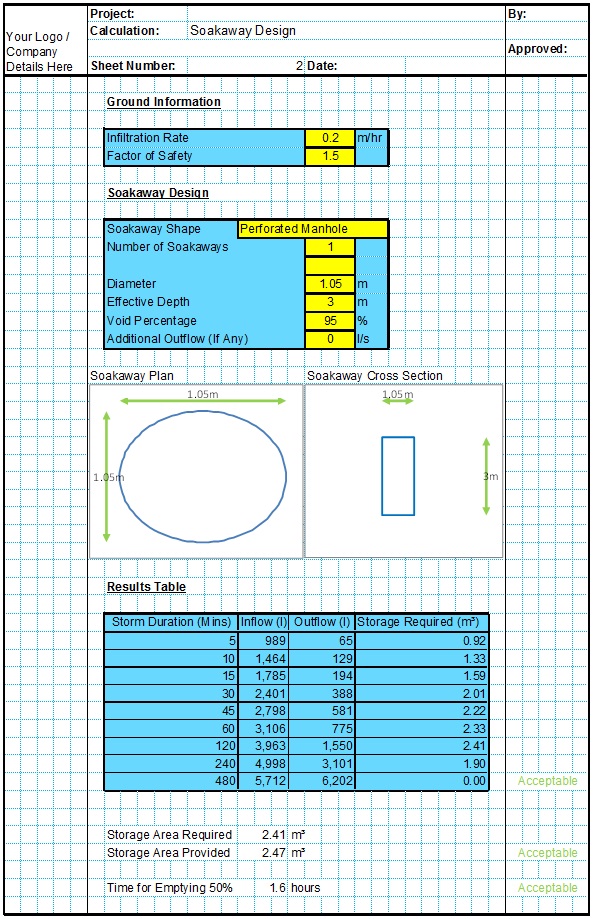

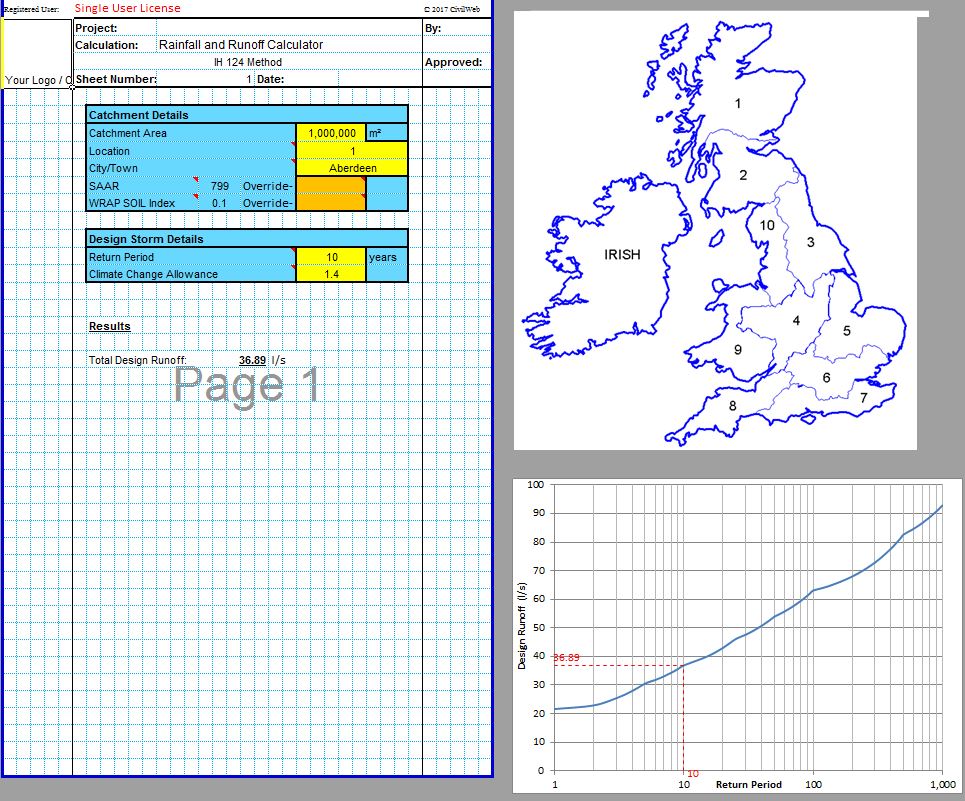

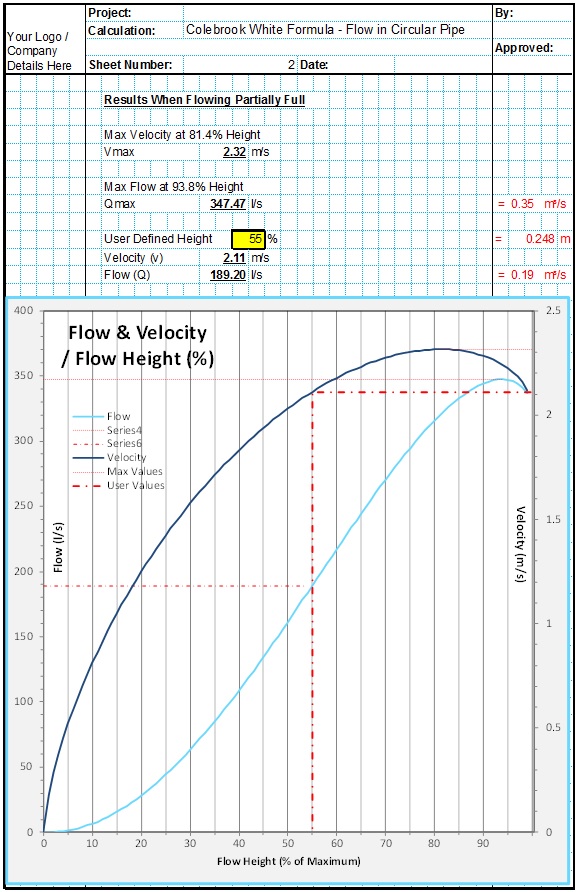

Generally a balance will need to be made between the permeability and the sediment sizes which are retained. The permeability will need to be sufficient to allow the french drain to perform as required. If this leads to a french drain filter fabric which allows small particles to migrate into the french drain this will require a more thorough inspection and maintenance schedule and perhaps a reduced expected deign life before the filter material needs to be replaced. Migration from surrounding soils can be prevented with an impermeable barrier if required, though this will not allow infiltration of runoff into the surrounding soils. A compromise may be to specify a highly permeable geotextile at the top allowing the water to enter the french drain, and a lower permeability geotextile to the bottom and sides of the french drain to allow some infiltration of runoff while preventing the migration of particles from the surrounding soils. This reduced infiltration rate will need to be taken account of in the design of the french drain if infiltration is required. Infiltration trenches can be designed using the CivilWeb Soakaway Size Calculator spreadsheet.

Impermeable Barriers

Where infiltration into the surrounding soils is not desired the french drain can be lined with an impermeable barrier often known as a geomembrane. There are three main different types of geomembrane available;

- Polymeric Geosynthetic Barriers – These include simple plastic sheets such as PVC, polyethylene and polypropylene.

- Bituminous Geosynthetic Barriers

- Geocomposite Clay Geosynthetic Barriers – These barriers consist of two layers of geotextile with a layer of bentonite clay sandwiched between. These are also often known as geocomposite clay liners (GCLs). These are typically specified where a large head of water is maintained above the barrier such as at the bottom of a storage tank. They are not commonly specified for french drains.

If properly installed any of the above barriers will prevent water from leaking out of the french drain and into the surrounding soils. However thinner materials are much more likely to be punctured during installation which can lead to leakage. The detailing of the membrane should avoid any tensile stresses which can lead to failure of the membrane. Careful installation is also very important as damage during handling and installation is the main cause of leakage through membranes. The membrane should be carefully transported and stored in order to reduce the likelihood of damage onsite before installation. The designer should ensure that the specified membrane has suitable tensile strength and puncture/tear resistance to survive the installation process. This can depend on the type of filter material and the installation methods employed.

French Drain Filter Fabric Installation

It is also important that all joints and seams of french drain filter fabrics are detailed correctly with an appropriate overlap and that this is undertaken during installation. Inspections will be required to ensure that the membrane is installed in accordance with the french drain detail.

Taped joints are not typically suitable for impermeable membranes as they are likely to leak. If the joints of polymeric membranes are to be welded, the designer must ensure that the membrane is thick enough for a durable joint to be created. Membranes less than 1mm thick are prone to welding related defects such as burn holes. Thicker membranes can however be more difficult to install, particularly around corners and tricky details. If a thin membrane is to be welded a test joint can be installed and then tested to ensure that the joint can be welded adequately.

In some cases it can be necessary to install a protective geotextile either above or below the membrane in order to protect it from angular aggregates or from loading during construction. This is often done for polymeric membranes which can tear and puncture easily.

French Drain Filter Fabric Detailing

Example detail drawings are included in our French Drain Detail post. Typically the french drain filter fabric should completely encase the filter materials including the top. The geotextile should include at least a 300mm overlap on top and should be placed around 200mm from the surface. The top layer should be filled with filter materials. This top layer can then be easily removed and replaced if it becomes clogged with sediments. This is particularly important where sheet flow is expected to flow into the french drain.

Get your copy of the CivilWeb French Drain Design spreadsheet now for only £20.

Or why not bundle with the CivilWeb Soakaway Design spreadsheet for only £5 extra?

Or save £50 by buying our full Drainage Design Suite including all our drainage design spreadsheets.

Download Free Trial Version

To try out a fully functional free trial version of this software, please Click Here or enter your email address below to sign up to our newsletter.