There are many standard french drain details which have been published in the past. In this post we explain the main components of french drain details and give some examples.

Bedding & Filter Materials

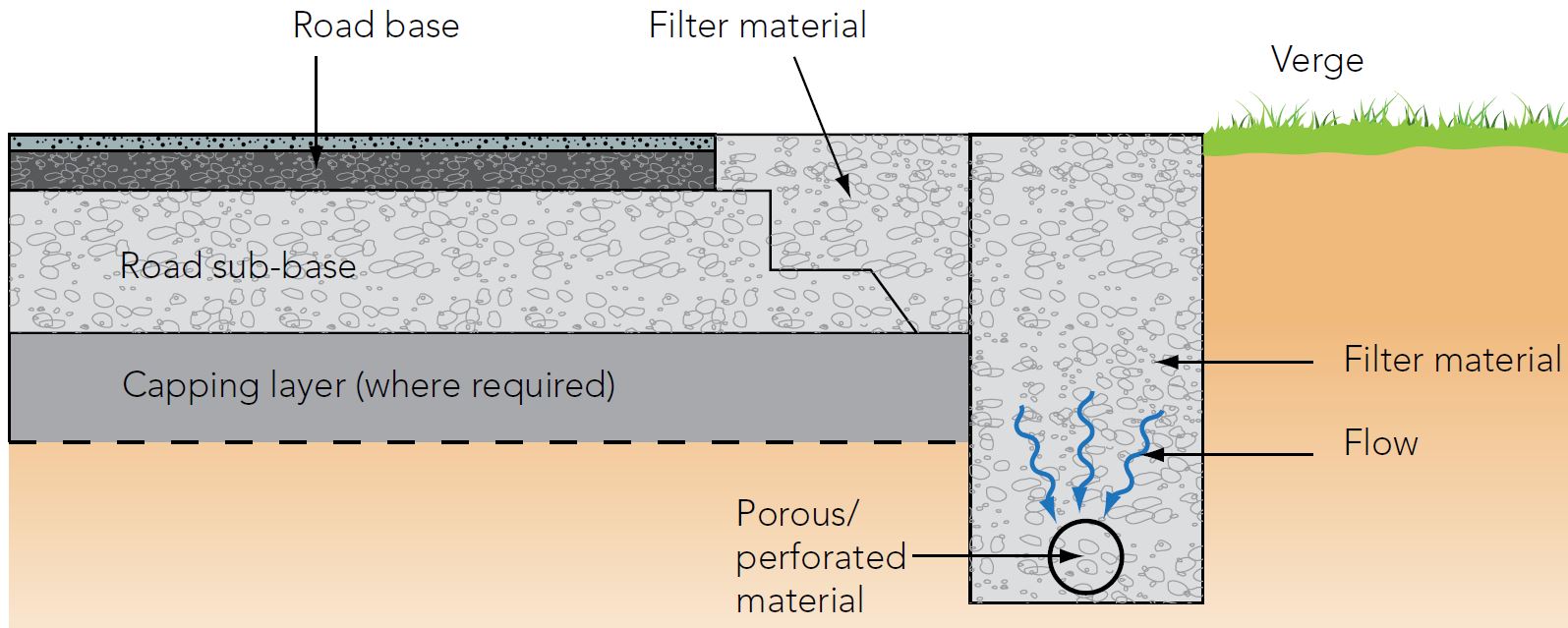

The french drain detail should consist of an excavated trench lined with a suitable geotextile french drain filter fabric. Then bedding material is installed in the bottom of the trench. The type and depth of bedding material depends on the structural design of the pipe as described in our French Drain Depth post.

However for untrafficked french drains the bedding will consist of a 75mm layer of either Type A filter material or a granular bedding material similar to normal drainage pipes. Onto this bedding layer the perforated pipe is installed to correct line and level and a constant grade. Next the french drain is backfilled with filter material. Again this can depend on the structural requirements but generally for lightly trafficked applications this should consist of Type B filter material up to the top 150mm – 300mm.

French Drain Depth

The depth of the french drain will depend on both structural and hydraulic design parameters. This is explained in detail in our French Drain Depth post.

French Drain Width

The width of the trench will normally be dependent on the minimum trench width required for the perforated pipe installation detail but can be modified in some cases to increase the runoff flow through the filter material towards the perforated pipe. This is explained in detail in our French Drain Width post.

Topping

The top 150mm - 300mm of the french drain will be designed depending on any level of filtration required or any structural requirements. If the french drain is lightly trafficked the geotextile filter fabric will be terminated before the topping layer with suitable overlaps to ensure durability. The topping will consist of either more Type B filter material, Type A filter material or a finer filter material or grassed topsoil designed to remove silt and small sediments from the runoff. This topping layer can then be easily removed, cleaned and replaced when it starts to become clogged with sediments or debris.

Where the french drain runs directly alongside a road, a verge of filter material should also be installed in order to accommodate the construction layers of the road, as shown in the below diagrams.

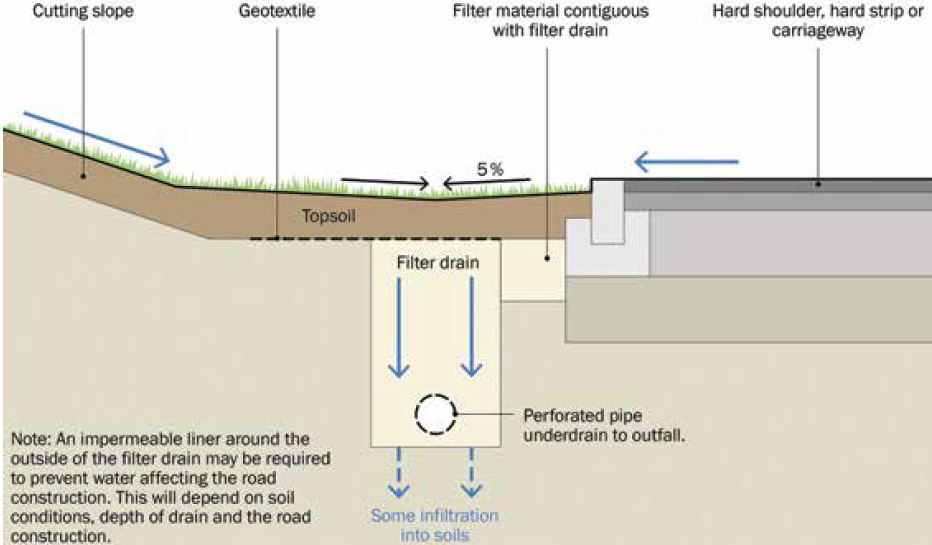

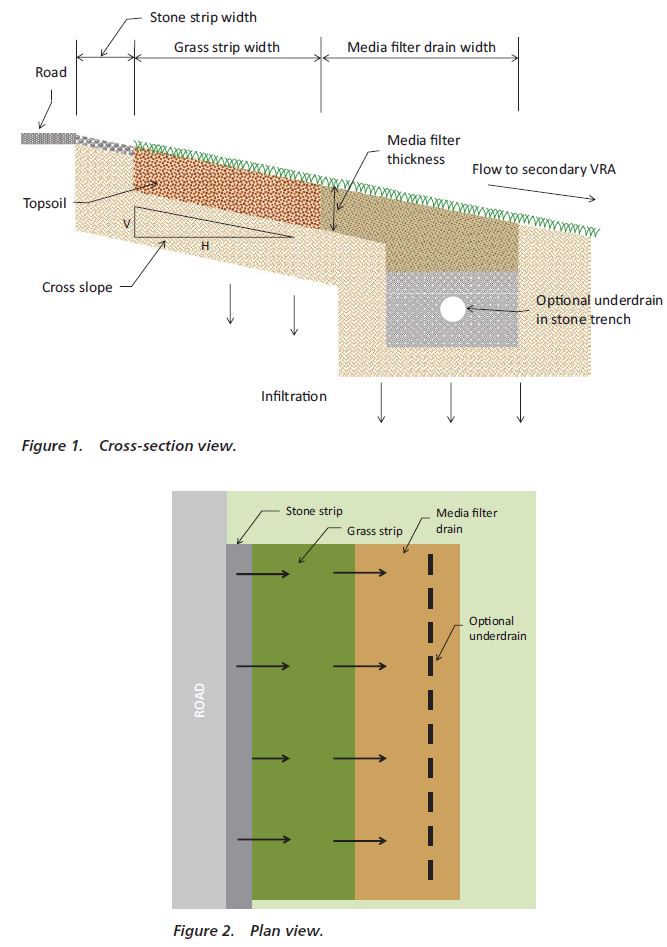

French Drain Detail - Filter Strips

In most cases, particularly with highways, french drains will perform best alongside a filter strip. The filter strip acts as a sediment control device. A standard french drain construction detail is provided below showing a french drain operating alongside a filter strip beside a road.

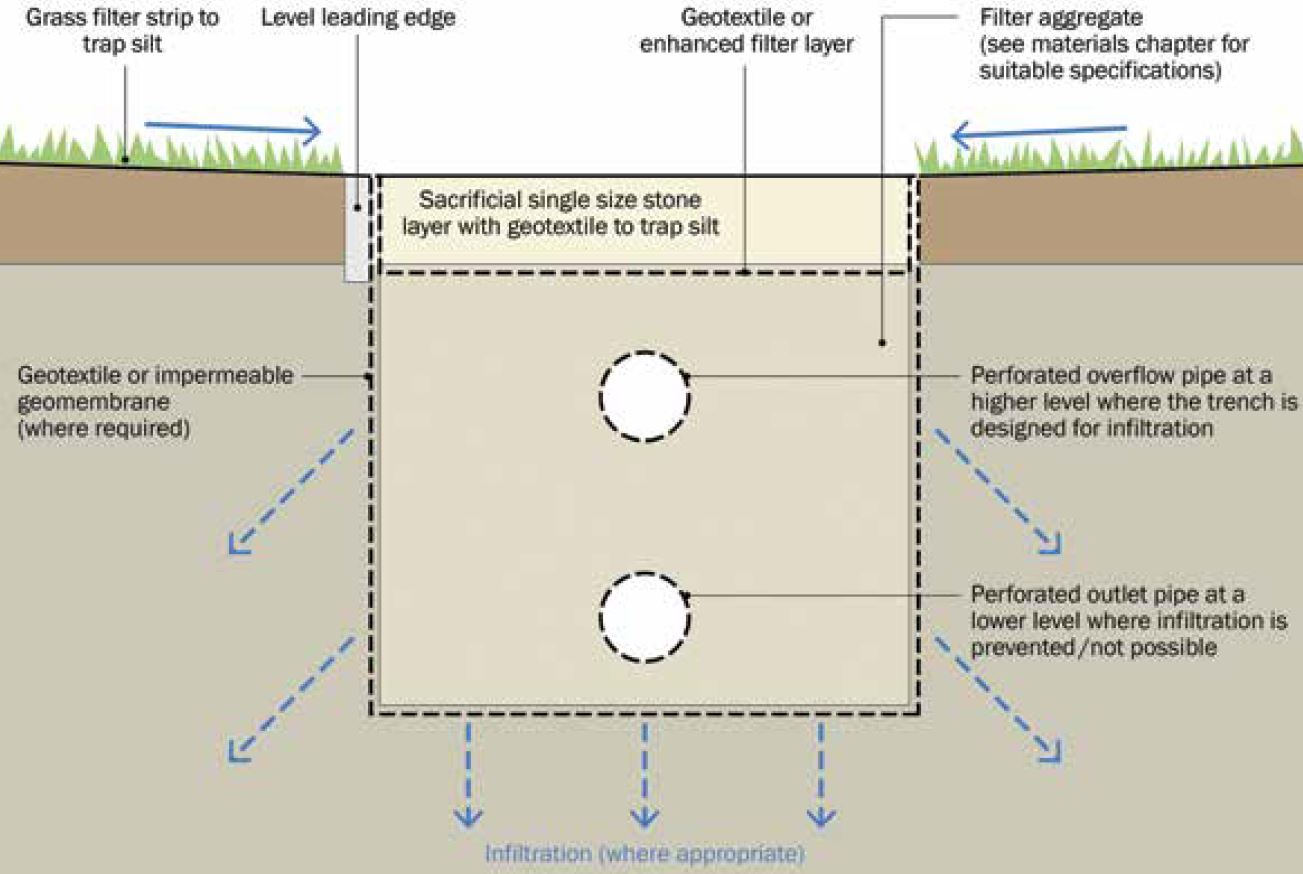

Overflow Perforated Pipe Installation Detail

In some cases there may be a requirement for a second perforated pipe installed at a higher level to provide an overflow to the french drain. This type of french drain detail may be required in areas where the failure of the french drain could lead to damage of property or danger to people.

Where the french drain is designed as an infiltration trench, a high level pipe can act as an overflow for large storm events which would otherwise overload the infiltration trench. In some cases no lower level pipe is installed at all, with only the higher level pipe providing an escape for large flows. A similar perforated pipe installation detail is illustrated below.

Narrow French Drains & Fin Drains

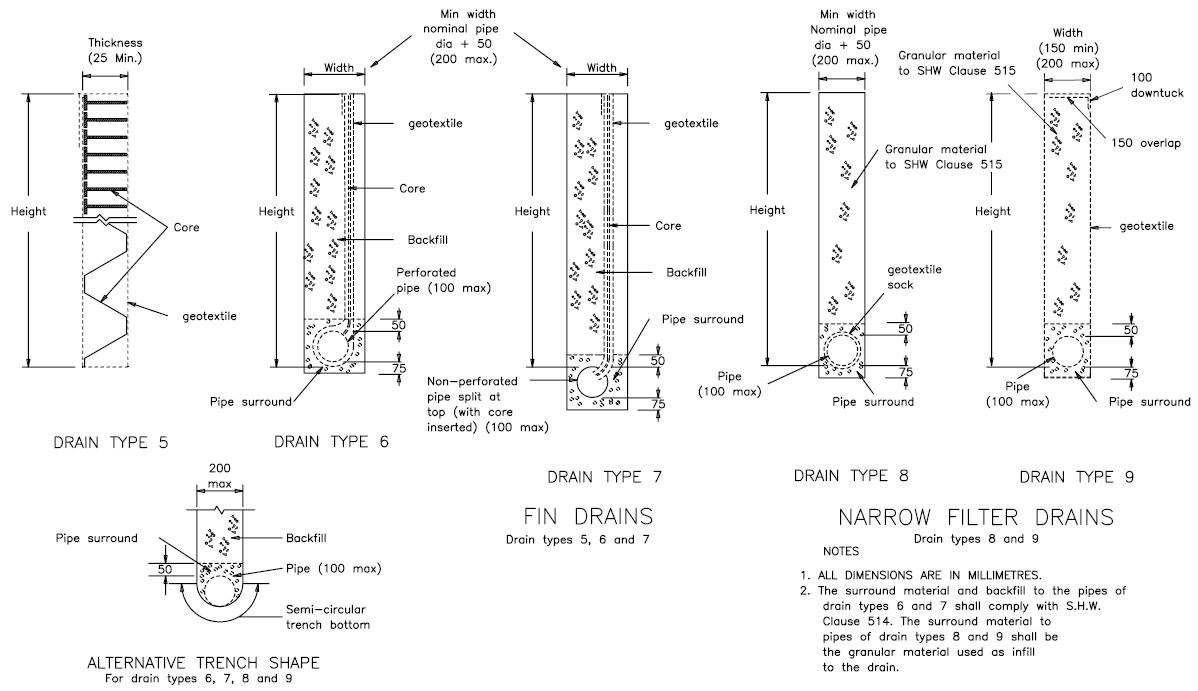

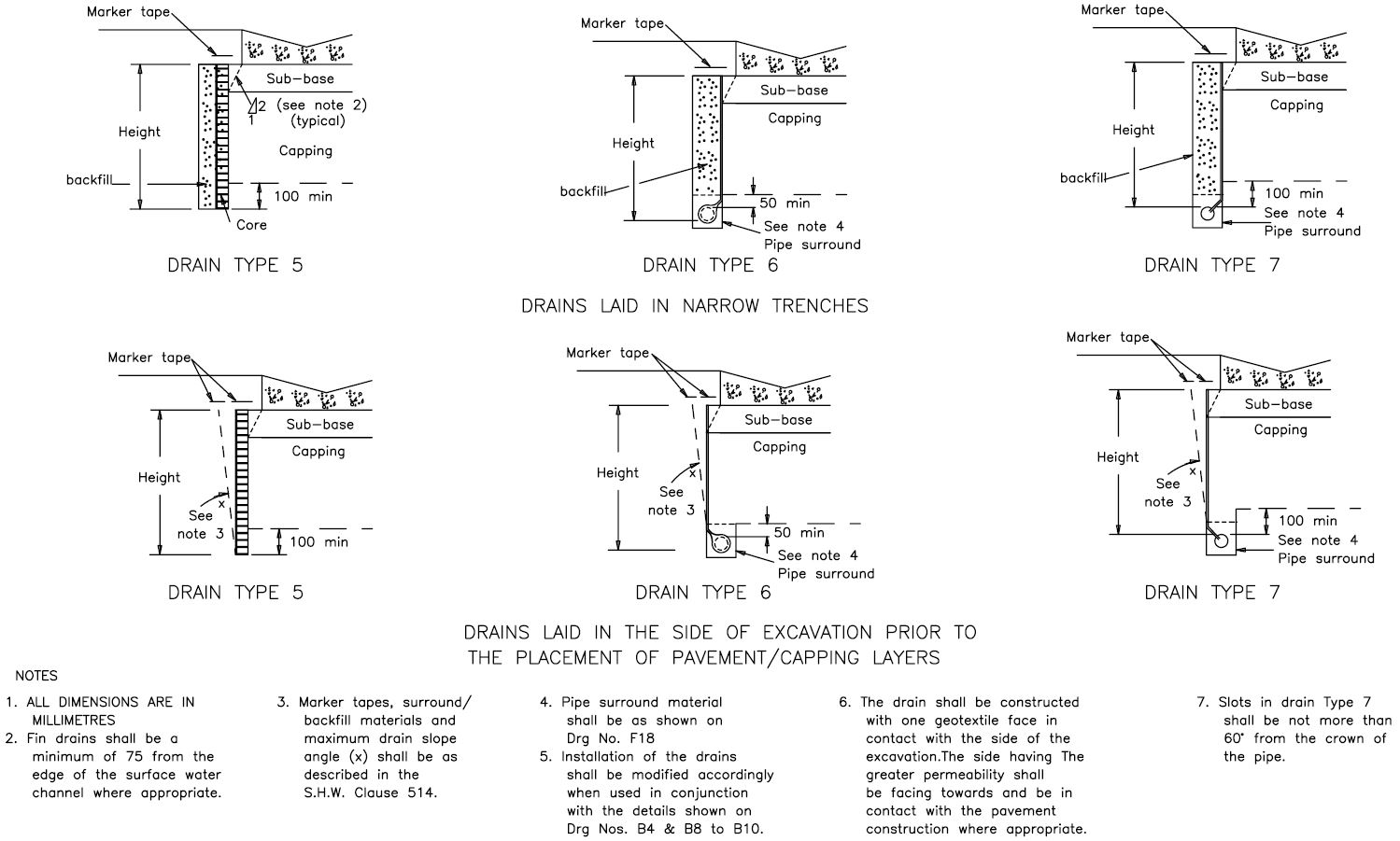

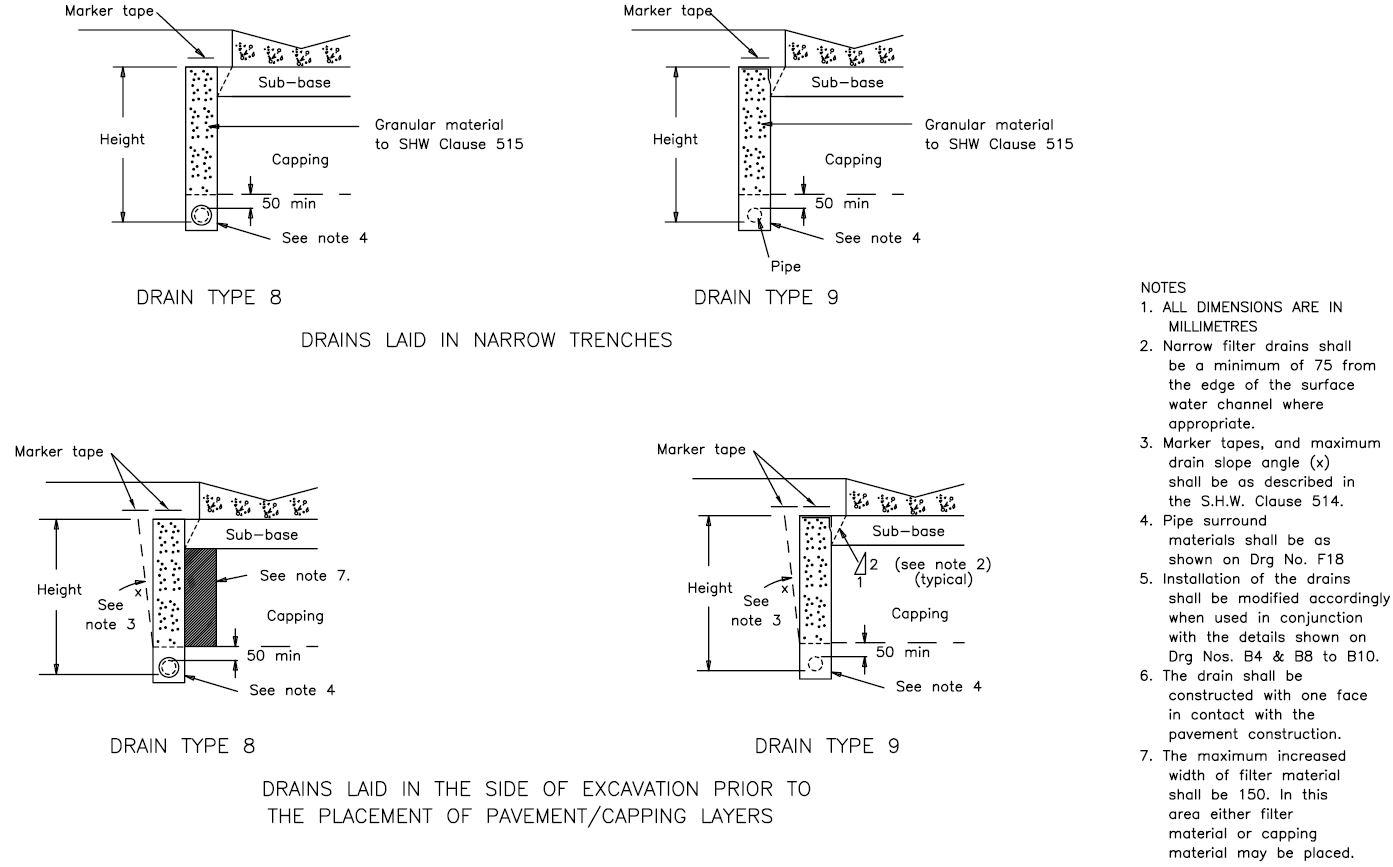

The following french drain construction details have been published by the Highways Agency for narrow french drains and fin drains for use on highways. Further details are included in our Fin Drains post.

French Drain Filter Material Specification

The design of the filter material is an essential part of the french drain design both from a hydraulic and water quality standpoint. The filter material used for french drains is typically coarse material designed for its hydraulic properties rather than finer material designed for water quality requirements.

Commonly Specified Filter Materials

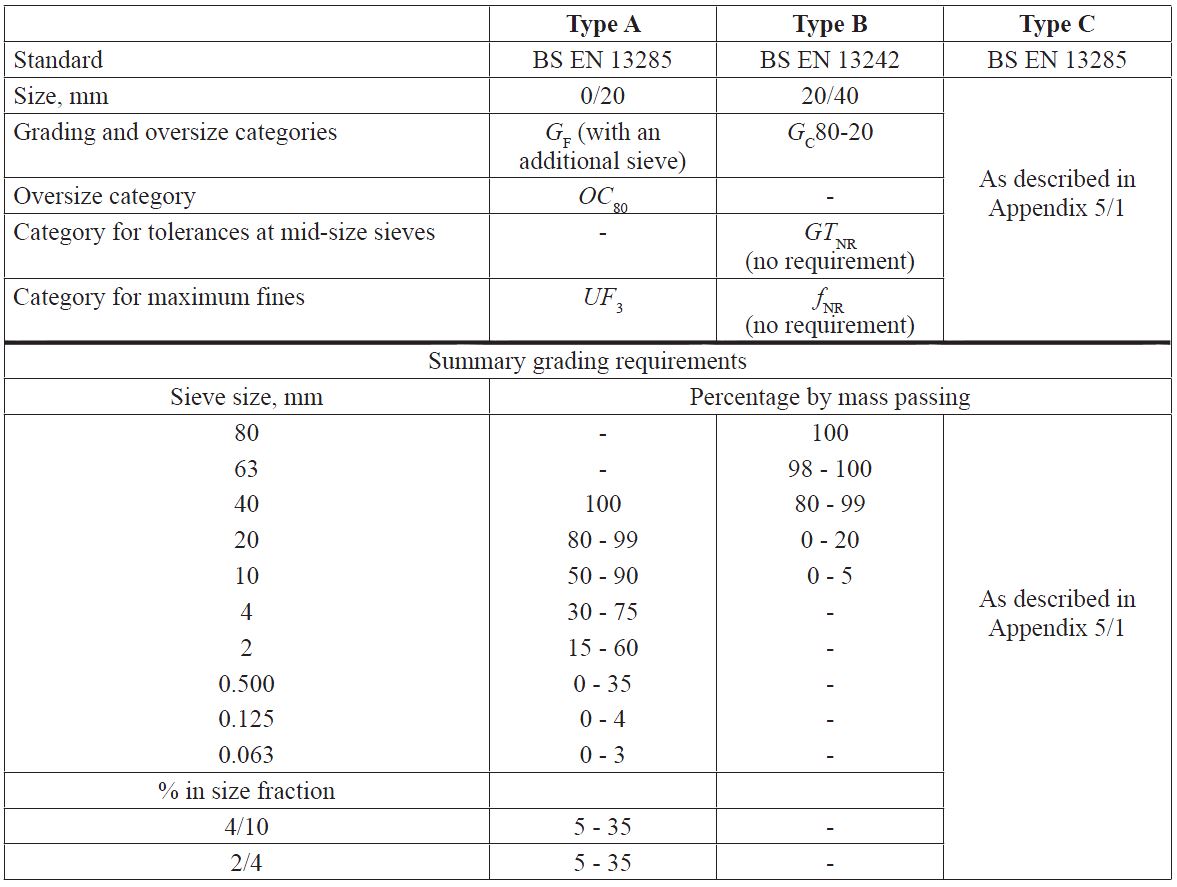

The filter material used in french drains is typically specified as a Type A, B or C material as defined in the Specification for Highway Works clause 505 and Table 5/5. The SUDS Manual recommends using Type B material. The Specification for Highway works also notes the following requirements;

- The filter material should have a resistance to fragmentation of LA50 in accordance with BS EN 13242. The Los Angeles Coefficient should be determined in accordance with the procedure in BS EN 1097-2.

- The filter material should have a water-soluble sulfate content of less than 0.38% of sulphate as SO3. This should be tested in accordance with the procedure outlined in BS EN 1744-1.

- The filter material must be non-plastic when tested in accordance with the procedure outlined in BS EN 1377-2.

If filter material is to be placed within 500mm of concrete, asphalt or bound sub-bases the following conditions must also be met to ensure there are no detrimental effects on the road;

- The water-soluble sulfate (WS) content of the filter material must not exceed 1,500mg/l of sulfate as SO4.

- The oxidisable sulfides content of the filter material must not exceed 0.5% of sulfate a SO4.

- The extract prepared for water-soluble sulfate testing must have a pH value of at least 7.2 when tested in accordance with the procedures outlined in BS 1377-3.

If the filter material is to be placed within 500mm of any structural steelwork it must also meet the following conditions;

- The water-soluble sulfate (WS) content must not exceed 300mg/l of sulfate as SO4.

- The oxidisable sulfides content of the filter material must not exceed 0.06% of sulfate a SO4.

The grading for Type B material is given in the below table taken from the Specification for Highway Works. This coarse graded 20/40 material will be coarse enough to prevent significant quantities of the filter material from entering the pipe through the perforations. It is however also much too coarse to prevent fine materials from migrating from the surrounding soils into the filter material and eventually into the perforated pipe. For this reason a geotextile filter fabric should always be specified for use with this particular filter material.

Coarse graded material such as Type B will offer no water quality benefits. Where there are concerns about the quality of the runoff entering the french drain, this must be dealt with upstream of the french drain using a filter strip or similar device. An impermeable membrane could also be used to prevent contaminated runoff from entering the groundwater through the french drain.

An alternative may be to use a fine filter material above the coarse graded material separated by a geotextile filter fabric layer. This may provide suitable treatment of the runoff before it enters the coarser filter material. Care must be taken that the finer filter material has sufficient permeability and does not become clogged over time. Further information can be found in our French Drain Water Quality post.

Recycled Materials

There is some scope for the use of recycled materials in french drains. The most common applications are detailed below;

- Recycled Aggregates – Recycled aggregates can be applied so long as they meet the requirements of the specification and the WRAP protocol. Crushed concrete can also be used though it is likely crushed concrete will be more useful in new concrete than in unbound aggregates such as filter material.

- Shredded Tyres – Bitmumen bonded shredded tyres can be used as a topping material to improve safety. A maximum thickness of 200mm of shredded car tyres will keep the layer above the water table as immersion of the layer can lead to groundwater contamination issues. Runoff water quality however is not affected.

Tyres used should be from either HGVs or larger earth moving equipment as these tyres contain a smaller proportion of steel and a thick rubber section which produces suitable rubber chunks when shredded. Car tyres are not generally suitable.

This topping layer will typically have a permeability of between 1.0m/s and 1.5m/s. While this is less than typical stone filled drains permeability of around 2.5m/s it should be more than sufficient for a french drain.

The inclusion of a shredded tyre topping layer will increase the stability of the topping layer under accidental loading from vehicles. The bitumen bound shredded tyre layer is sufficiently cohesive to resist the shear forces caused by vehicles turning and braking which can be a primary cause of damage to french drains installed besides highways.

Unbound tyre chips can also be used as a replacement for filter material. The chips must be cleanly cut so that there is no protruding steel. Rubber chips are however easily compressible and large strains are possible under loading.

- Glass – Recycled glass can be produced as either recycled glass sand or as crushed washed glass which can be graded into a suitable filter material. Large glass chunks are not desirable so a grading closer to Type A is likely to be more acceptable. The reduced permeability of a Type A grading compared with Type B should be taken into account.

- Granular Blast Furnace Slag – Blast furnace slags from steel manufacturing plants are commonly used as materials in the construction industry, particularly ground as an additive in concrete and as an aggregate in road construction. The slag must be allowed to weather to prevent leaching of calcium and sulphur from the surface of the slag into the groundwater. Once weathered the leachable compounds in the interior of the slag do not migrate to the outside. For this reason slag aggregates should not be used below the groundwater table.

However there is potential in some cases for mercury to leach from blast furnace slag so it should not be used in the vicinity of any aquifers or wells.

Interception of Sediments

The long term performance of the french drain depends on the quantity and size of sediments which are allowed to enter the french drain system with the runoff. In many cases some form of linear sediment control such as a filter strip is appropriate. Where concentrated inlets release water into the french drain a more concentrated form of sediment interception such as a catchpit or vortex separator may be more appropriate.

Further information on sediment control systems is available in our Interception of Sediments post. This was written for soakaway systems but is largely applicable to french drain systems too, particularly where infiltration into the surrounding soils is expected to occur through the french drain.

Interception of Oils

Where the french drain is used to accept runoff from car parks, roads or other areas which may be contaminated with oil, the french drain should include some method of intercepting any oils or fuels spilled on the catchment. Further information is available on our Interception of Oils post.

Get your copy of the CivilWeb French Drain Design spreadsheet now for only £20.

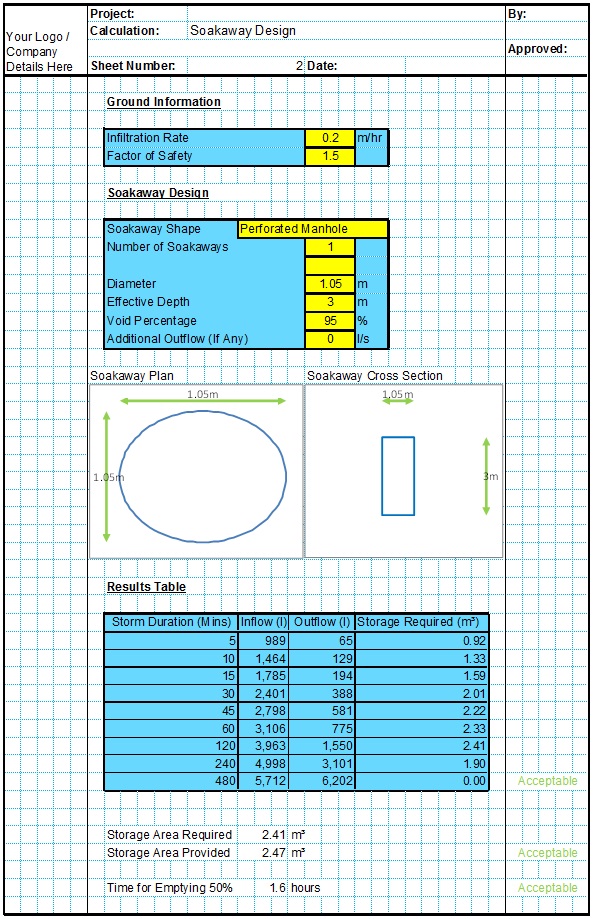

Or why not bundle with the CivilWeb Soakaway Design spreadsheet for only £5 extra?

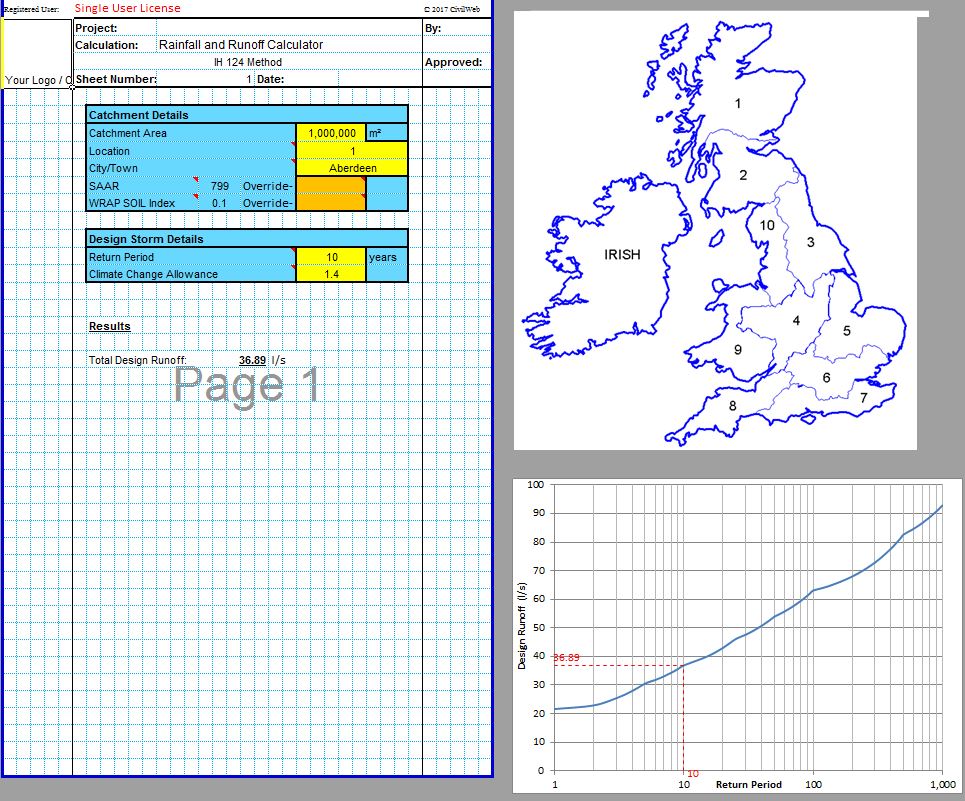

Or save £50 by buying our full Drainage Design Suite including all our drainage design spreadsheets.

Download Free Trial Version

To try out a fully functional free trial version of this software, please Click Here or enter your email address below to sign up to our newsletter.