Fly ash concrete describes concrete mixes which contain significant quantities of fly ash. Fly ash acts as a supplementary cementitious material in concrete as it will hydrate and displays cementitious properties. Fly ash added to concrete mixes usually reduces the quantity of cement in the mix making the mix cheaper and more sustainable. Fly ash concrete has a number of slightly different properties to ordinary Portland cement concrete, as detailed in this post.

Fly Ash for Concrete

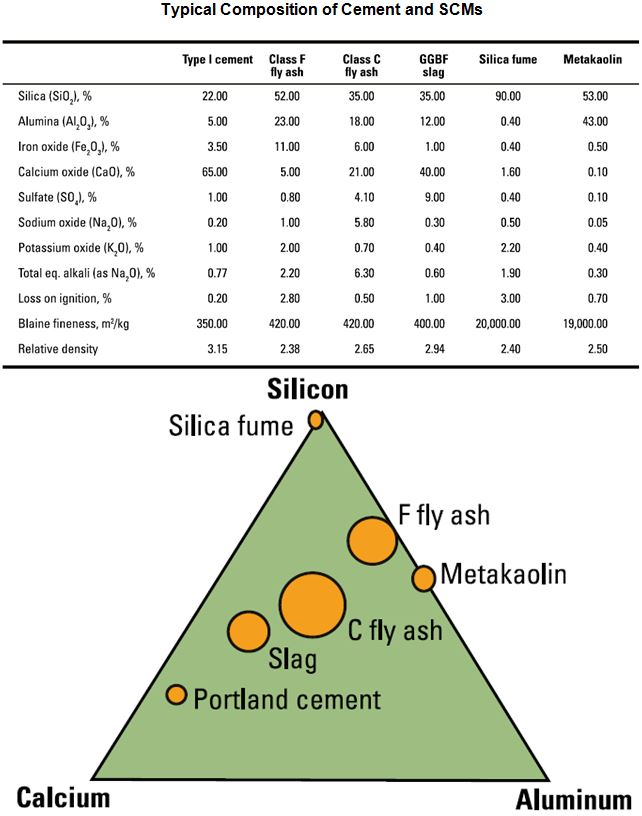

Fly ash is produced in coal fired power stations. It consists of the non-burnable materials left over when the coal is burned. It consists primarily of a silicate glass containing silica, alumina, iron-oxide and calcium. There are also smaller concentrations of sulfur, sodium, potassium and carbon. Typical compositions of Fly Ash along with cement and other SCMs are shown in the below diagram.

Fly ash looks similar to cement to the naked eye, but the particles are finer than cement and are spherical in shape, not angular like cement. The specific gravity of Fly Ash particles is generally between 1.9 and 2.8. Fly Ash has cementitious properties and can therefore be used as a substitute for a portion of cement in the concrete mix. Fly Ash should conform with the requirements detailed in BS EN 450 in the UK, or ASTM C618 in the US.

Advantages of Fly Ash in Concrete

Fly Ash is most commonly used in mass concrete applications due to the lower heat of hydration, however it is also commonly used in the UK for concrete pavements because it can improve workability, retard setting times in hot weather and reduce cost. The use of Fly Ash in concrete will affect the following properties which should be considered;

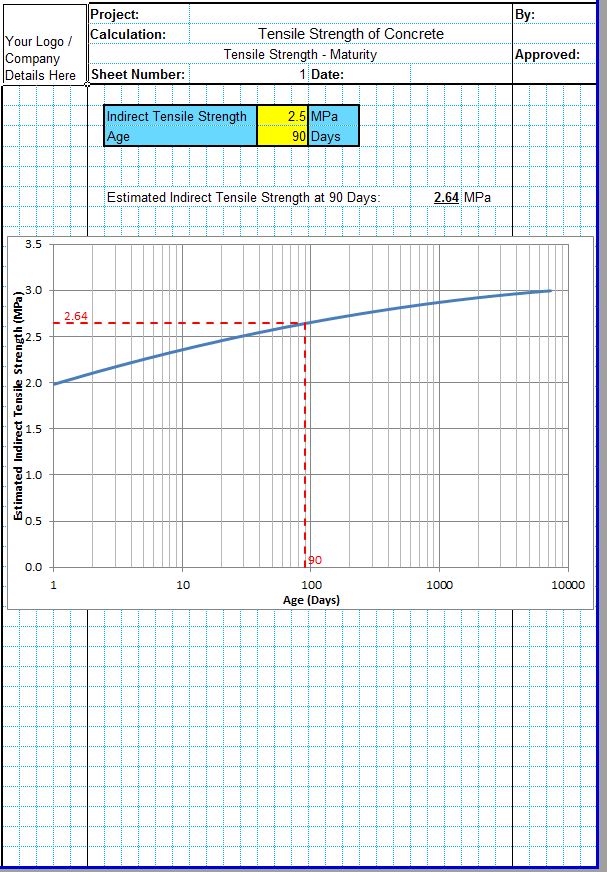

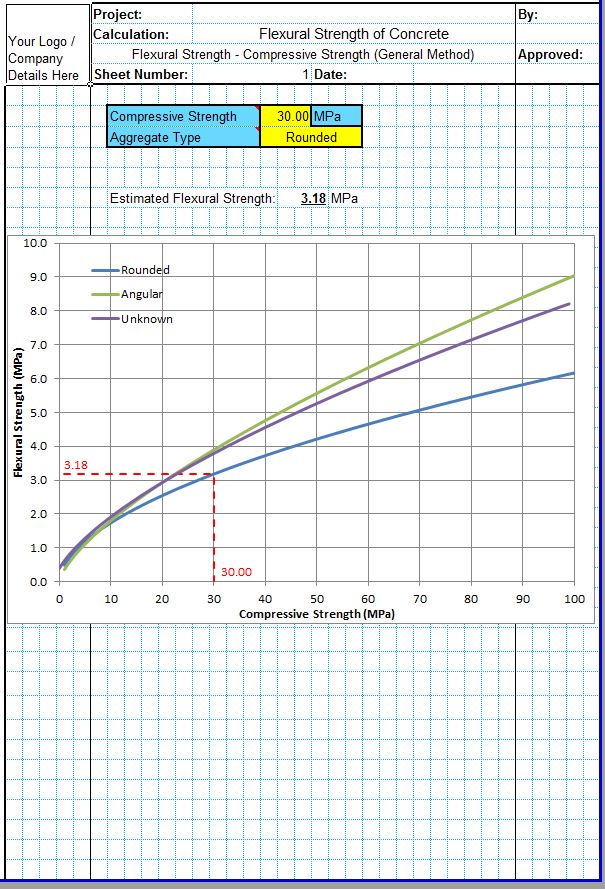

- The addition of Fly Ash will increase the final strength of the concrete. This is due to the fact that even though the initial reaction of Fly Ash is slower, it lasts longer than Portland cement. Replacing 40% of the cement was found to increase flexural strength by 30%, however it took 3 months to reach the strength of conventional concrete and 1 year to attain the 30% higher value. The variable nature of the material also led to an increased variability in final strengths.

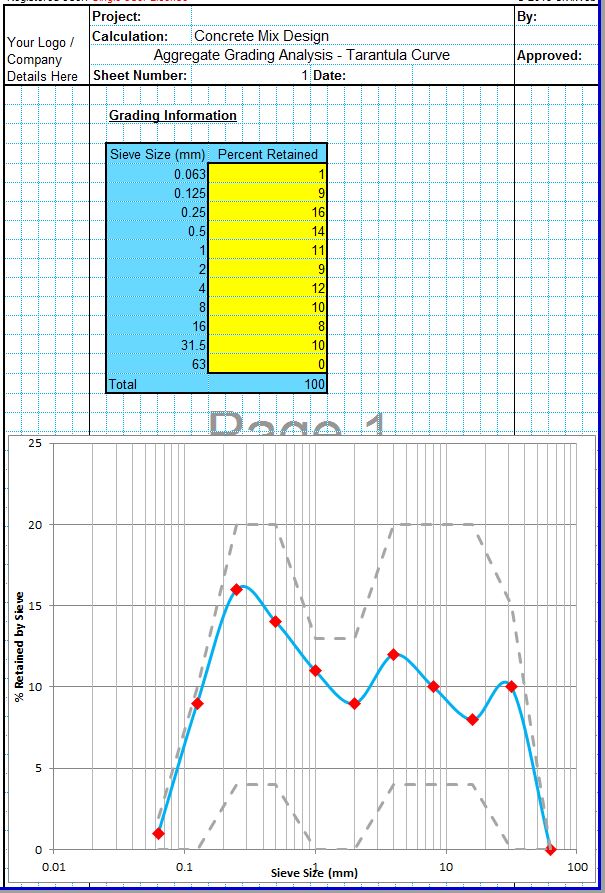

- Fly Ash concrete is more workable due to the spherical fly ash particles. This increase workability can be used directly or can be used to reduce the water content without compromising workability.

- Fly Ash concrete can also be slightly more durable due to a decreased permeability at the concrete surface. This can reduce chloride penetration from affecting reinforcing or embedded steel in certain conditions. Fly Ash mixes can also restrict the expansion of aggregates affected by Alkali-Aggregate Reactions.

- As an industrial byproduct there are also environmental and energy conservation positives in replacing some cement content which is very energy intensive to produce and preventing the Fly Ash from being disposed of.

Fly Ash in Concrete Problems

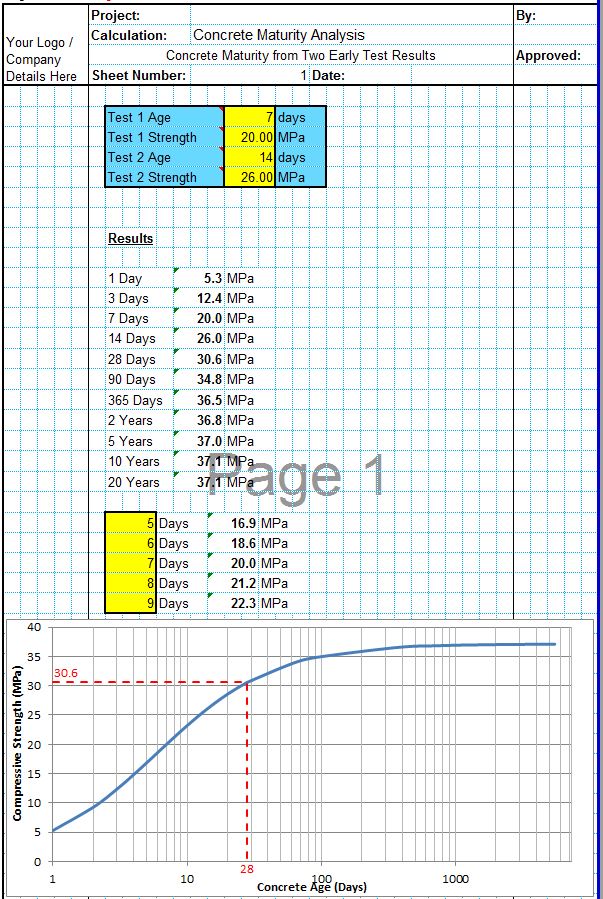

- As discussed above adding fly ash to concrete will slow the setting time and early strength gain of the concrete, even if the ultimate strength is likely to be higher.

- The addition of Fly Ash also has an effect on the performance of air entraining admixtures. This is due to the varying quantities of carbon in the Fly Ash which makes it more difficult to control the air content. The loss on ignition of the Fly Ash should not exceed 3% to prevent the carbon from absorbing significant amounts of any air entraining admixtures.

Replacement of Cement by Fly Ash in Concrete

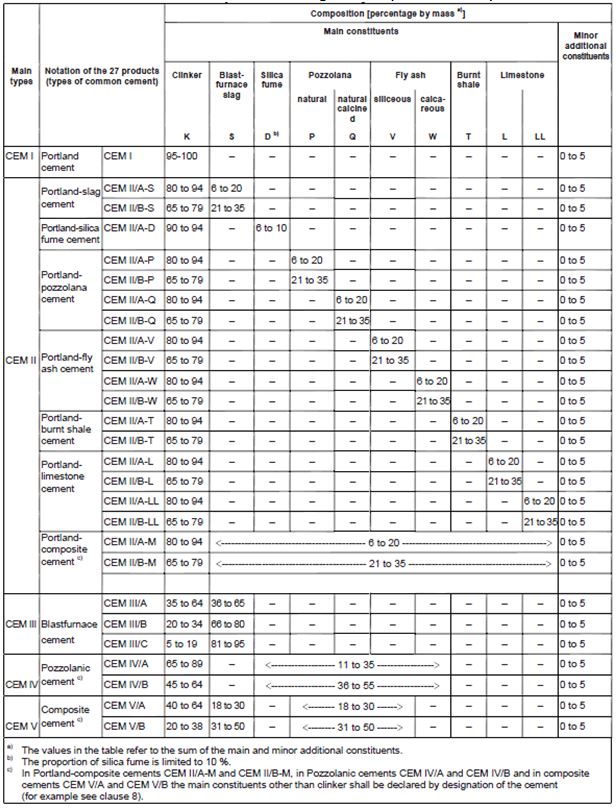

The quantity of Fly Ash must be between 6% and 35% in order to comply with BS 8500-1. A table showing the composition limits of cement combinations in accordance with BS EN 197-1 is shown below.