The grading of aggregates in concrete is an important part of concrete design as the grading of the aggregates affects the workability of the fresh concrete, the cement content and therefore cost of the mix and shrinkage of the finished concrete.

The CivilWeb Grading of Aggregates in Concrete Analysis Spreadsheet includes four unique tools for analysing the grading of aggregates for concrete to ensure that the grading is suitable. The spreadsheet can be purchased at the bottom of this page for only £5.

Importance of Grading of Aggregates in Concrete

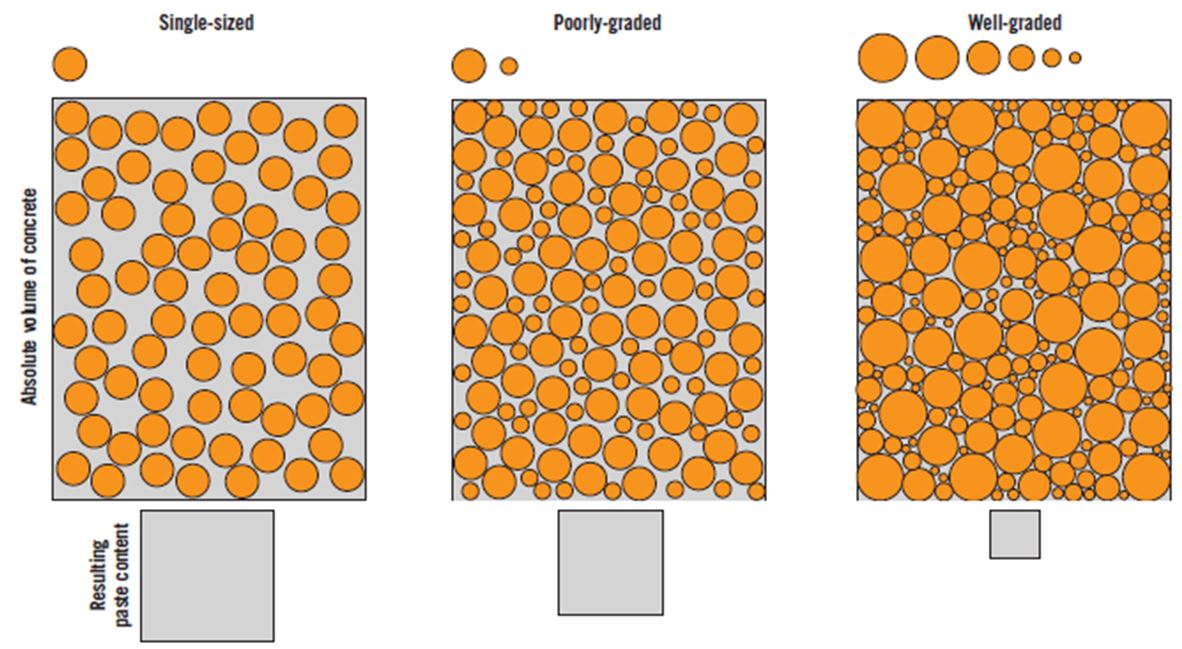

The importance of grading of aggregates in concrete is mostly related to the workability of the fresh concrete mix and the associated water and cement contents. The combined grading of the aggregates determines the ratio of aggregates and cement paste contained within a particular volume of concrete. Aggregates used in concrete are relatively stable both dimensionally and chemically and for this reason it is generally desirable for the concrete to maximize the amount of aggregates and minimize the amount of cement paste.

A well graded aggregate concrete mix will fill more of the voids between the coarse aggregate particles and reduce the amount of locking between the coarse aggregates. This both reduces the amount of cement required to fill the voids and improves the workability of the concrete mix.

Poorly Graded Aggregates

Poorly graded aggregates used in concrete will contain a higher volume of voids which must be filled by cement paste. More paste in the concrete mix will lead to higher shrinkage and higher costs. Poorly graded aggregates in concrete also increases the surface area of aggregates which must be coated in cement paste in order for the mix to remain sufficiently workable.

Poorly graded aggregates in concrete also increase the risk of the concrete being more difficult to finish and increase the likelihood of segregation during compaction.

Gap Graded Concrete

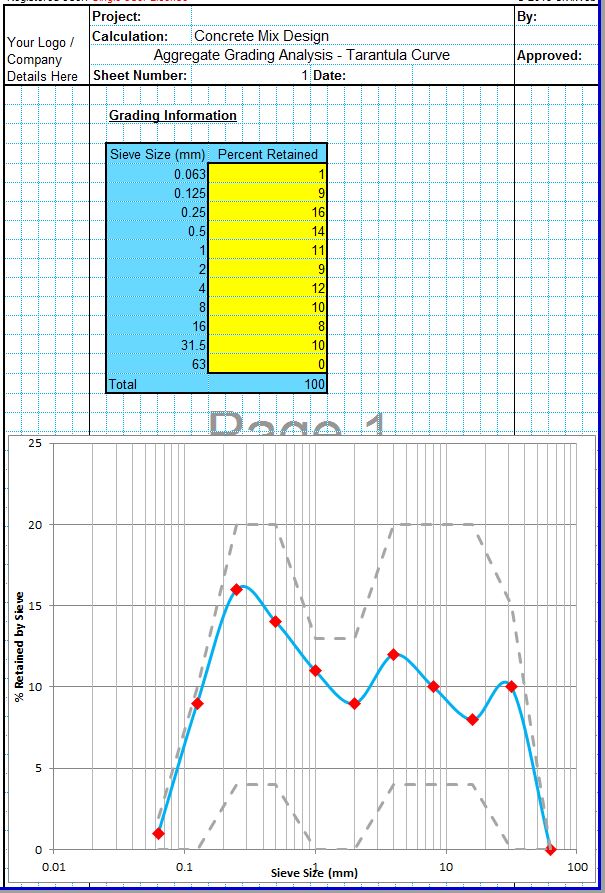

A gap graded concrete describes a concrete mix where there is a gap between the fine aggregates and the coarse aggregates. A gap graded concrete mix is shown in the below diagram. Gap graded concrete mixes require more cement and then well graded aggregate concrete mixes and often become sticky and difficult to finish due to the large fine aggregate content.

A gap graded aggregate mix will lead to reduced workability, greater water and cement requirements and can lead to excessive bleed water. Gap graded fine aggregates can also lead to excessive bleeding and reduced finishability.

Gap graded concrete mixes are often created inadvertently. This can happen when the grading of the coarse aggregate and the grading of the fine aggregate may have been developed in isolation. This can lead to a combined grading of aggregates which has gaps between the grading of the fine aggregates and the grading of the coarse aggregates.

Grading of Coarse Aggregates

In order to avoid gap graded concrete mixes, it is important that the grading of the fine aggregates and the grading of the coarse aggregates are undertaken together. The grading requirements for coarse aggregates must suit the combined grading of aggregate. This often requires the inclusion of some medium sized particles along with the coarse aggregates. Otherwise the combined grading of the aggregates can be achieved by mixing more than two sources of aggregates, not just the fine aggregate and the coarse aggregates.

Grading of Fine Aggregates

The grading and total content of fine aggregates is important as this affects the workability of the mix as well as contributing to a continuous well graded combined aggregate grading. Further information can be found in our Grading of Fine Aggregate post.

Measuring the Grading of Aggregates in Concrete

The grading of aggregates in concrete is usually measured using a sieve analysis which uses a series of sieves to capture and separate aggregates of different sizes, allowing the aggregate distribution to be measured. The sampling and testing of aggregate gradations is completed in accordance with BS EN 932 and BS EN 933.

Optimizing the Grading of Aggregates in Concrete

To avoid a poorly graded aggregate mix, often 3 or 4 different aggregates mixes will be required with at least one intermediate sized aggregate to fill the gaps between the coarse aggregate and the fine aggregate. There may even be a requirement for a second intermediate aggregate grading to fill any grading gaps in the fine aggregate.

Grading of Aggregates in Concrete Analysis Tools

The CivilWeb Grading of Aggregates in Concrete Analysis spreadsheet uses three different techniques to analyze the suitability of proposed grading of aggregates for a concrete mix. These techniques are the 0.45 Power method, the Coarseness Factor method and the Tarantula Curve method. Each method provides a different insight into the suitability of the grading of the aggregates.

These methods analyze the combined grading of the aggregates, not the grading of fine aggregates and grading of coarse aggregates individually. This prevents gap graded concrete aggregate mixes from being specified inadvertently.

The CivilWeb Grading of Aggregates in Concrete Analysis spreadsheet is available for purchase below for just £5. The tool is also included in the Concrete Properties Suite which includes many more useful tools for only £10.

CivilWeb Grading of Aggregates in Concrete Analysis Spreadsheet

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.