GGBS concrete is concrete which contains a significant volume of ground granulated blast furnace slag (GGBS) in the mix as either a supplementary cementitious material or as a replacement for some of the ordinary Portland cement. GGBS concrete behaves in a similar manner to fly ash concrete and affects the setting time, strength gain and workability of the concrete.

GGBS Physical Properties

GGBS used in concrete is a byproduct of metallurgical processes, most commonly the blast furnace production of iron from iron ore. The molten slag is quickly cooled with water and then ground into a fine powder. This powder is a latent hydraulic material and can therefore be used as a substitute for Portland cement without the presence of added calcium. GGBS cement should conform to the requirements of BS EN 15167 or ASTM C989 in the US.

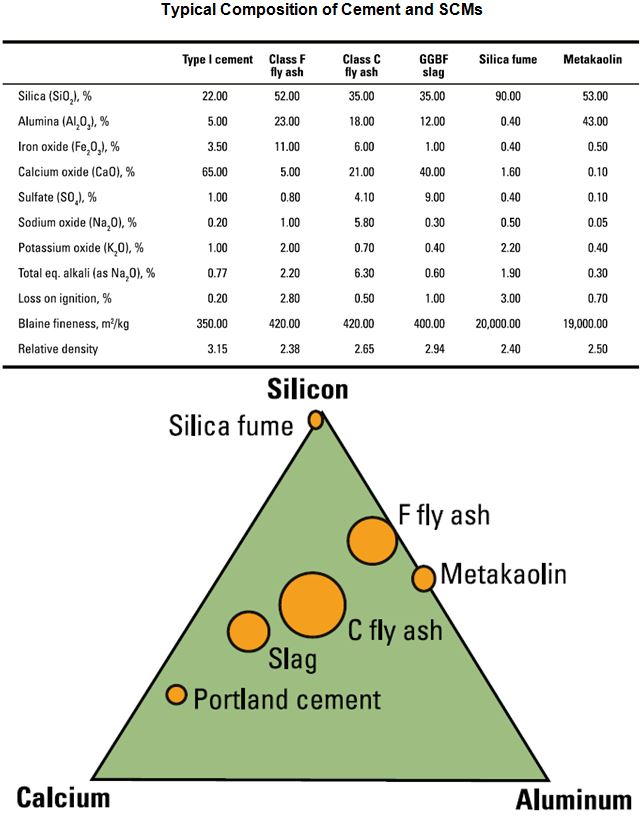

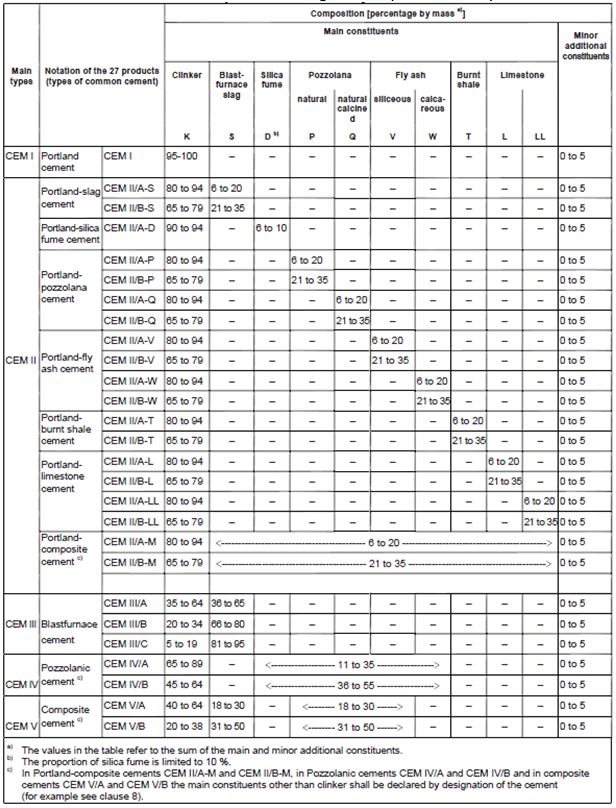

GGBS cement is similar in composition to Portland cement. When mixed with Portland cement this forms Portland Slag Cement or Blast-Furnace Cement, depending on the proportions. See below for composition details of GGBS concrete.

GGBS Properties

The properties of GGBS concrete mix are similar to the effects of Fly Ash concrete as described in our Fly Ash Concrete post.

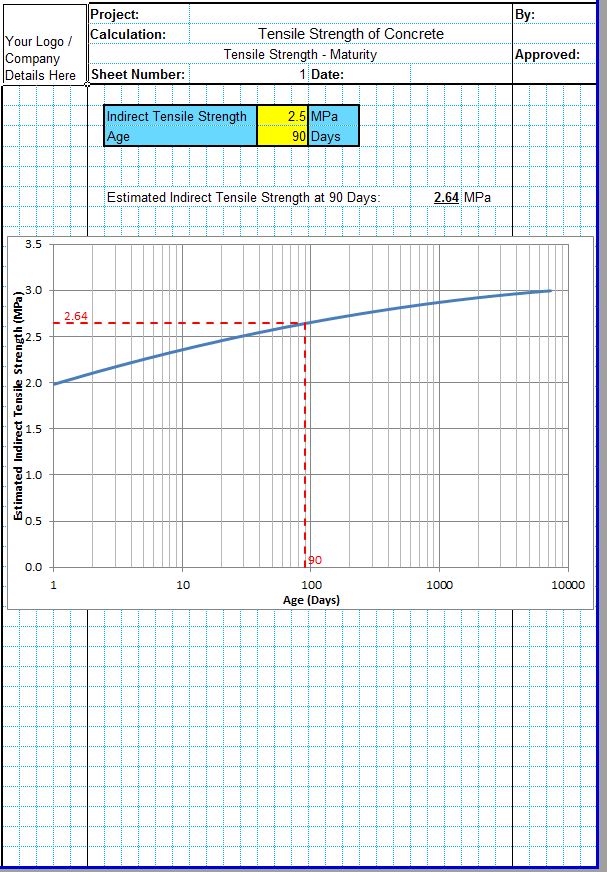

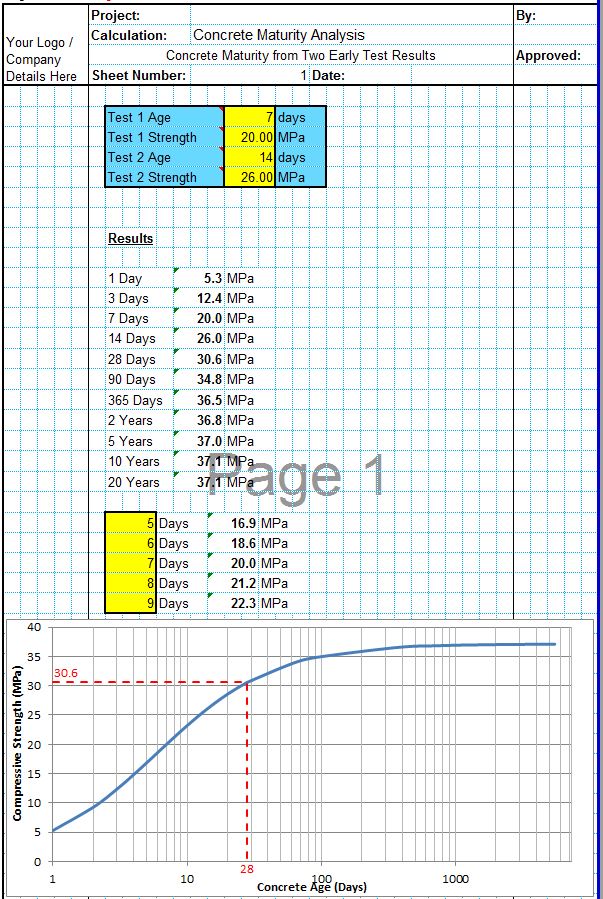

- Effects on setting time, early strength and final strength are similar to Fly Ash mixes. GGBS concrete will set more slowly than ordinary Portland cement concrete and will gain strength more slowly. GGBS concrete mixes do however tend to have a higher ultimate strength than Portland cement mixes though it can take several months for GGBS concrete mixes to overtake Portland cement mixes which gain strength more quickly. This can limit the use of GGBS in concrete for some applications where early strength is important.

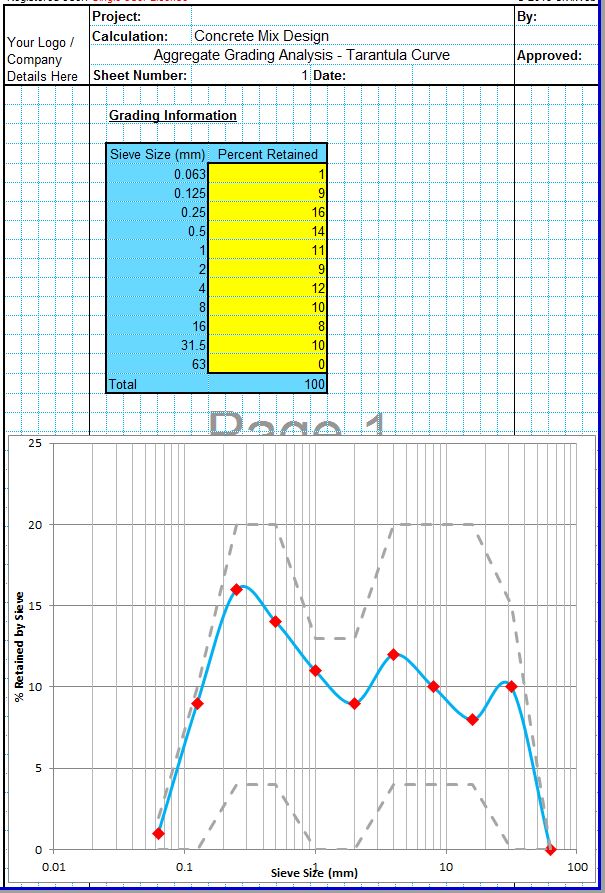

- GGBS will improve the workability and reduce the required water content of the concrete, though to a lesser extent than Fly Ash.

- The effects on permeability and chloride/sulfate penetration are similar to Fly Ash. The reduced permeability can have beneficial durability effects, particularly where embedded reinforcement steel may otherwise be subjected to attack from chlorides.

- GGBS does not interfere with air entraining admixtures as Fly Ash can.

- GGBS has similar environmental benefits as Fly Ash. As a waste product GGBS cement reduces the amount of Portland cement used and prevents the GGBS cement from being discarded.

GGBS Concrete Mix Design

The quantity of GGBS cement must be between 6% and 65% in order to comply with BS 8500-1. For concrete pavements it is recommended that the proportion of GGBS does not exceed 35% to reduce the risk of freeze-thaw damage on the weaker concrete and to prevent issues with extended and variable setting times.