The compressive strength of concrete measures its ability to resist forces trying to push the concrete together. The compressive strength of concrete is generally proportional to the volume of voids in the concrete matrix. Voids provide a shorter route for cracks to propagate through the concrete. These voids may be large air voids caused by poor placing or compaction, small voids introduced through air entrainment or capillary voids left when excess water in the mix has evaporated. For this reason the prime parameters controlling the compressive strength of the concrete are the quality of the workmanship, the water-cement ratio which determines the capillary void volume, and the extent to which hydration has been allowed to progress.

The CivilWeb Compressive Strength of Concrete Spreadsheet includes a number of useful tools for concrete mix design and analysis as detailed below. This suite of spreadsheets is available for £5 on its own, or it is provided free with the CivilWeb Rigid Pavement Design Spreadsheet which costs £20.

Compressive Strength of Concrete

The compressive strength of concrete is a measure of the concrete’s ability to resist forces trying to compress or push the concrete together. Concrete is very strong in compression, particularly in comparison to the concrete’s strength in tension and flexure which are relatively weak. This is due to the microstructure of the concrete paste-aggregate matrix and the inherent strength of the rock aggregates used. There is little free space available for the concrete matrix to be compressed, leading to a high compressive strength.

Due to the disparity between the compressive strength of concrete and its weakness in tension, the pure compressive strength of the concrete is rarely the single defining strength parameter. Simple structural concrete members will be reinforced with steel. In this case the steel reinforcement provides the tensile strength, and the concrete provides the compressive strength. In this case the compressive strength of concrete is the defining strength parameter only because the concrete is not expected to provide any tensile strength at all.

Compressive Strength Relationship with Other Strength Parameters

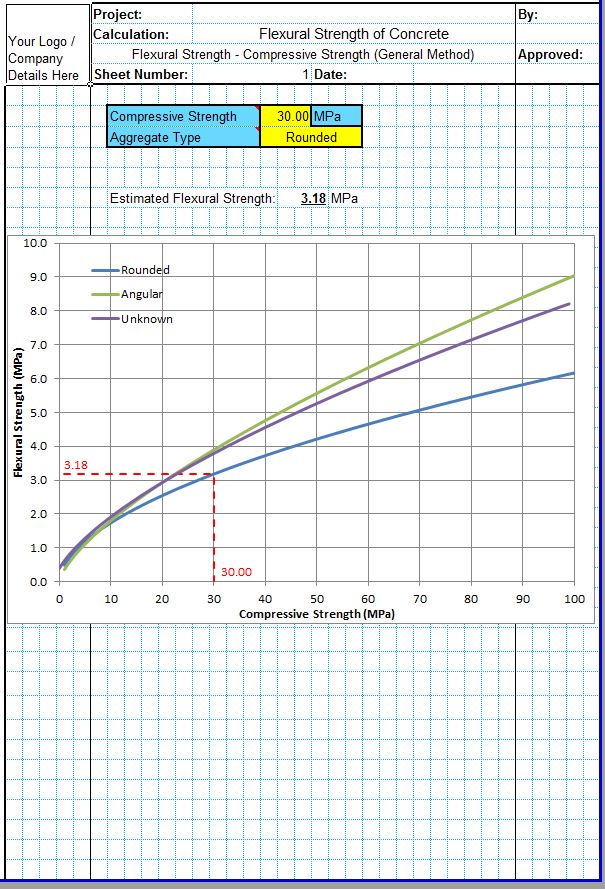

Compressive strength is often used a proxy for other strength parameters as the compressive strength test of concrete is much easier and cheaper to complete than tensile strength test or the flexural strength test. This is common practice for concrete pavements and other concrete components which rely on the flexural strength of the concrete.

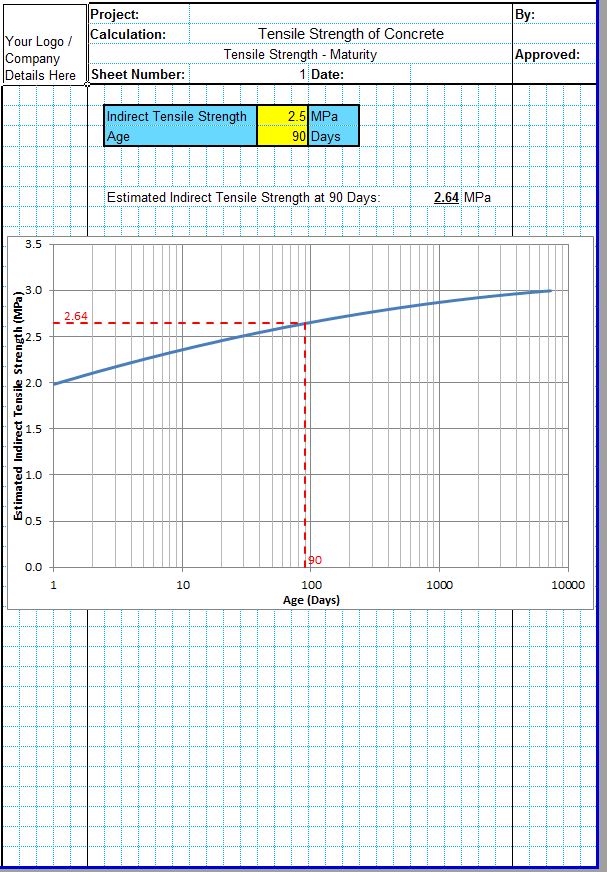

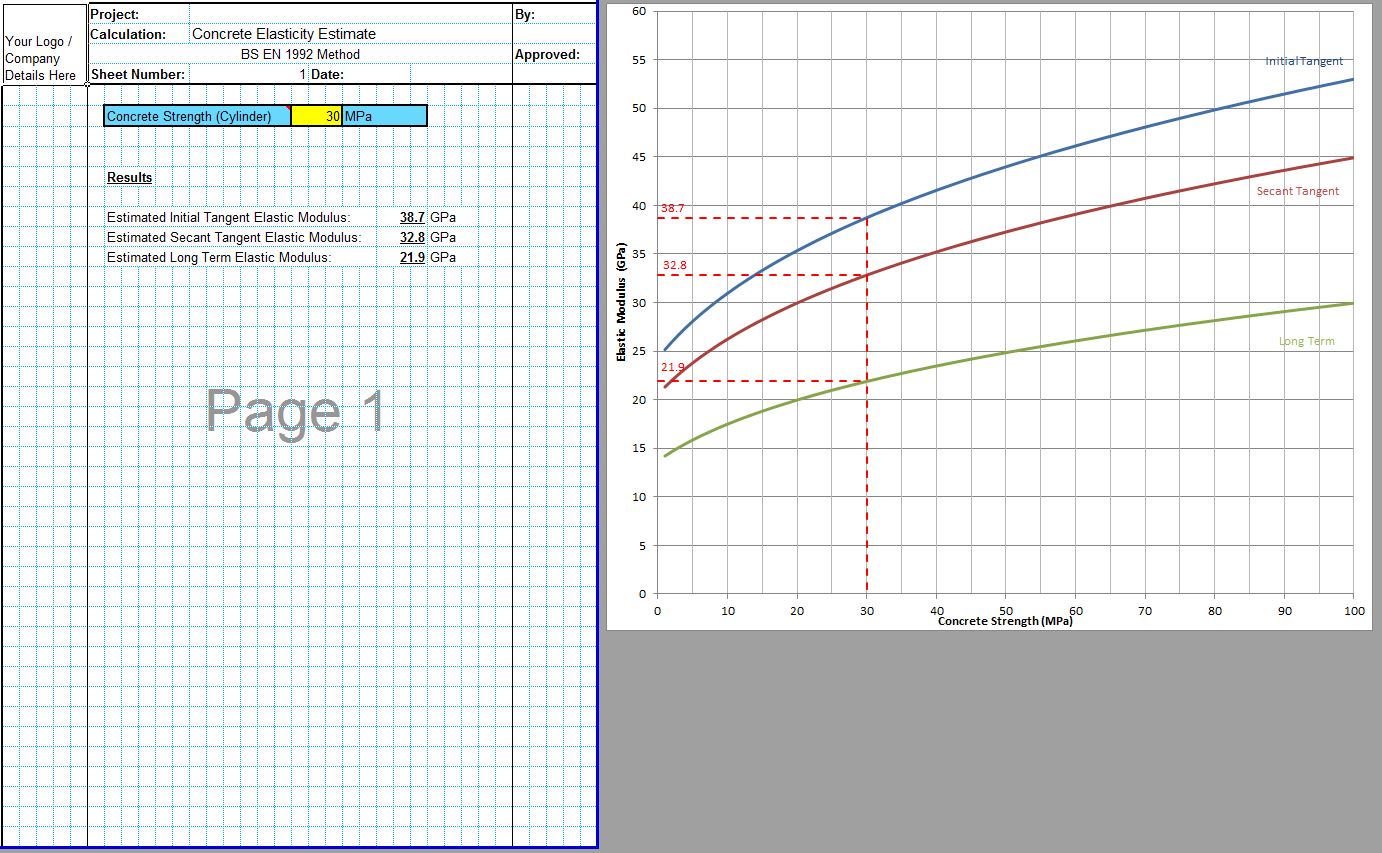

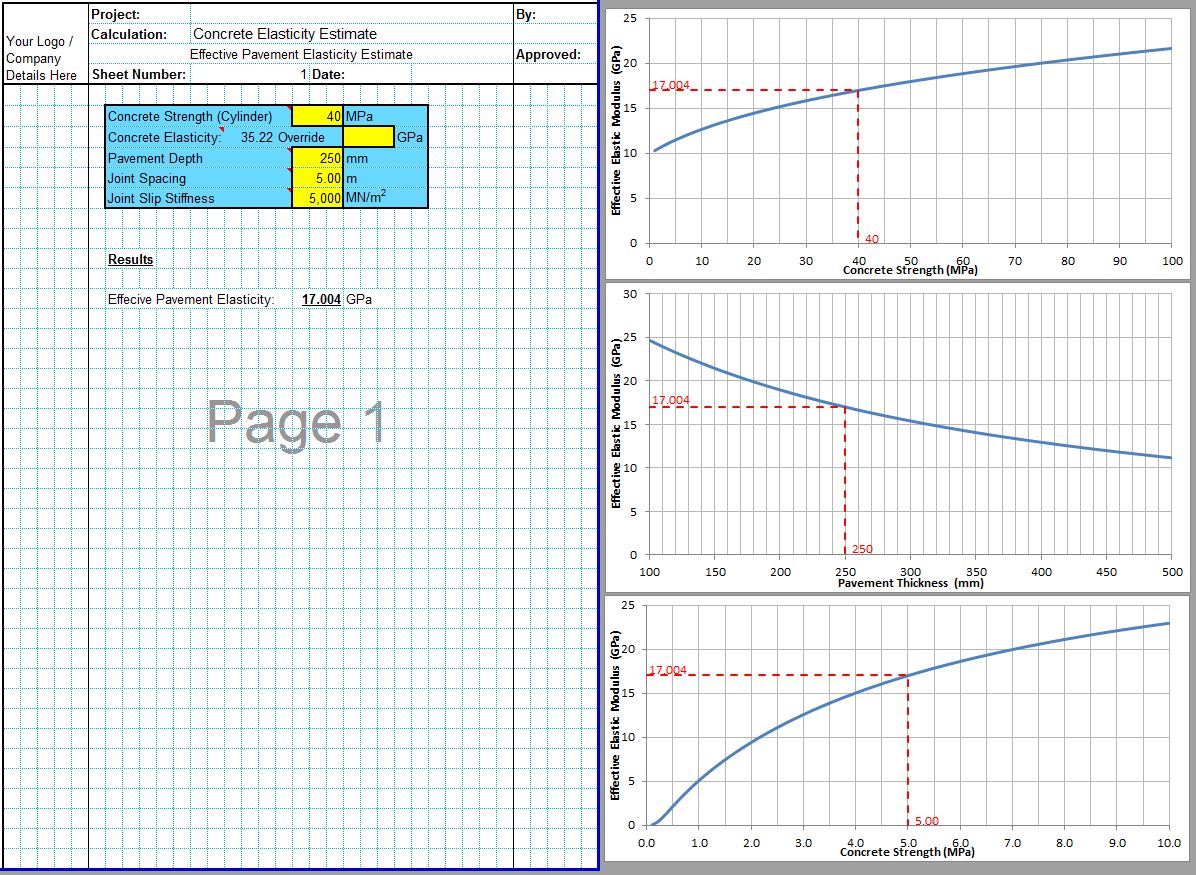

In order for concrete cube test results to be used with a correlation for another strength parameter, a relationship must be determined between the compressive strength of the concrete and the alternative strength parameter required. This correlation relationship changes from mix to mix so a mix specific correlation should be determined where the parameter considered is particularly critical. In other cases general relationships can be suitable. These general relationships are detailed in our Tensile Strength of Concrete and Flexural Strength of Concrete posts. Spreadsheets to calculate these properties are also included in the Concrete Properties Calculator Suite which can be purchased at the bottom of this page for only £10.

Compressive Strength of Concrete as an Indicator of Other Properties

While the compressive strength of the concrete is often not critical, it is still usually specified and measured as part of the quality assurance process. Often compressive strength is used as a proxy for a number of other desirable concrete properties simply because it is a straightforward, cheap and well known property to test with a concrete compression test.

In this way the compressive strength of concrete is often measured as an indicator of the concrete’s durability. High strength concrete is generally more resistant to freeze thaw cycles, and to penetration from chlorides, sulfates, acids or other chemicals which will have harmful effects on the concrete or any embedded steel. Compressive strength in this case is being measured as a proxy for the permeability of the concrete.

Generally this is a reasonable assumption given that concrete strength is partly dependent on the density of the concrete, and denser concrete will generally be less permeable. However where the permeability is critical such as where chlorides or sulfates are known to be present there are much better ways to specify and measure chloride resistant concrete than simply to specify and test a high strength concrete mix.

Characteristic Compressive Strength of Concrete

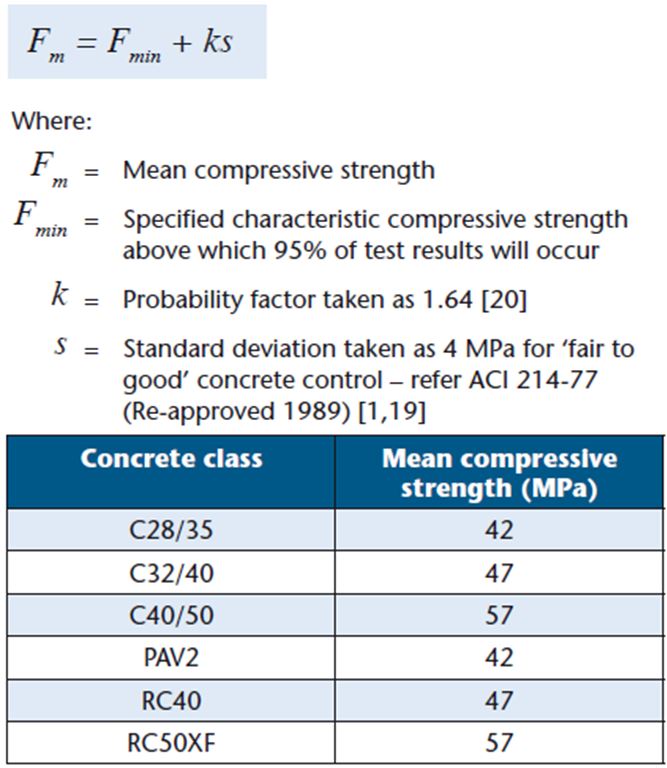

The compressive strength of the concrete as specified in a design or specification document generally refer to the characteristic 28-day compressive strength, above which 95% of test results will occur. This characteristic compressive strength value is related to the mean compressive strength by a defined relationship as shown below.

This relationship does not take into account the loss of compressive strength due to entrained air content. Nor does it allow for compressive strength gain beyond 28-days maturity, but this is the value most commonly used for design purposes. These strengths are those achieved for samples cured under laboratory conditions, so the actual strengths measured from cores taken from the insitu concrete will usually be significantly lower.

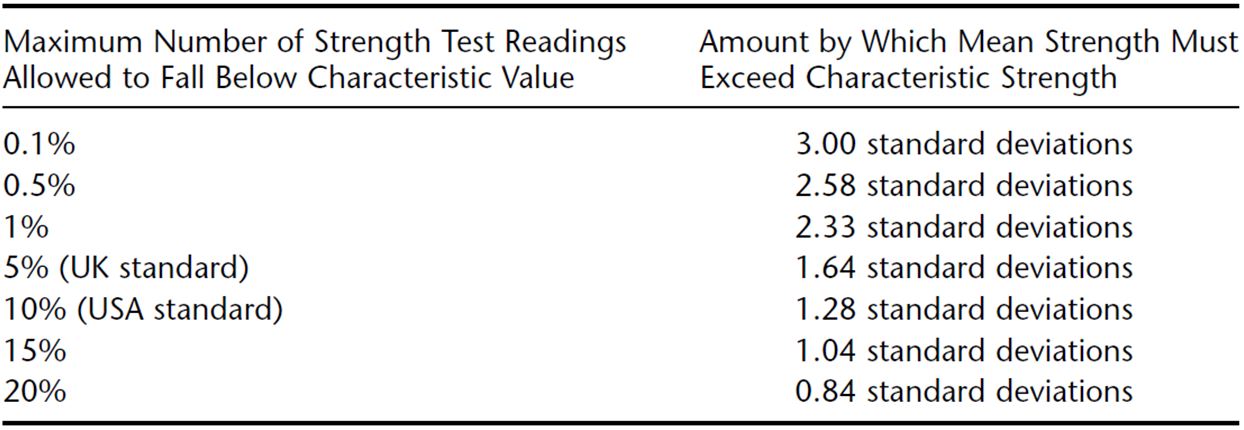

Different characteristic compressive strength of concrete values can be calculated to allow for a more or less conservative design by altering the probability factor k. The table below shows how the probability factor can be adjusted to calculate different characteristic values. Note this shows the UK standard value of 5% and the US standard of 10%.

A calculator tool is included in the CivilWeb Compressive Strength of Concrete Spreadsheet for calculating mean compressive strengths and characteristic compressive strengths. This can be used to design a concrete mix with an average compressive strength which will satisfy the required characteristic strength. Alternatively this can also be used to check whether the average compressive strength values from a small number of tests is likely to satisfy the required characteristic compressive strength or not.

Specified Compressive Strength of Concrete

In the UK concrete compressive strength tests involve the crushing of 150mm cubes. In the US and most of Europe the test involves crushing a 150mm diameter cylinder 300mm long. Cube results will generally be around 20% higher than cylinder results. Further details are included in our Concrete Cube Test post.

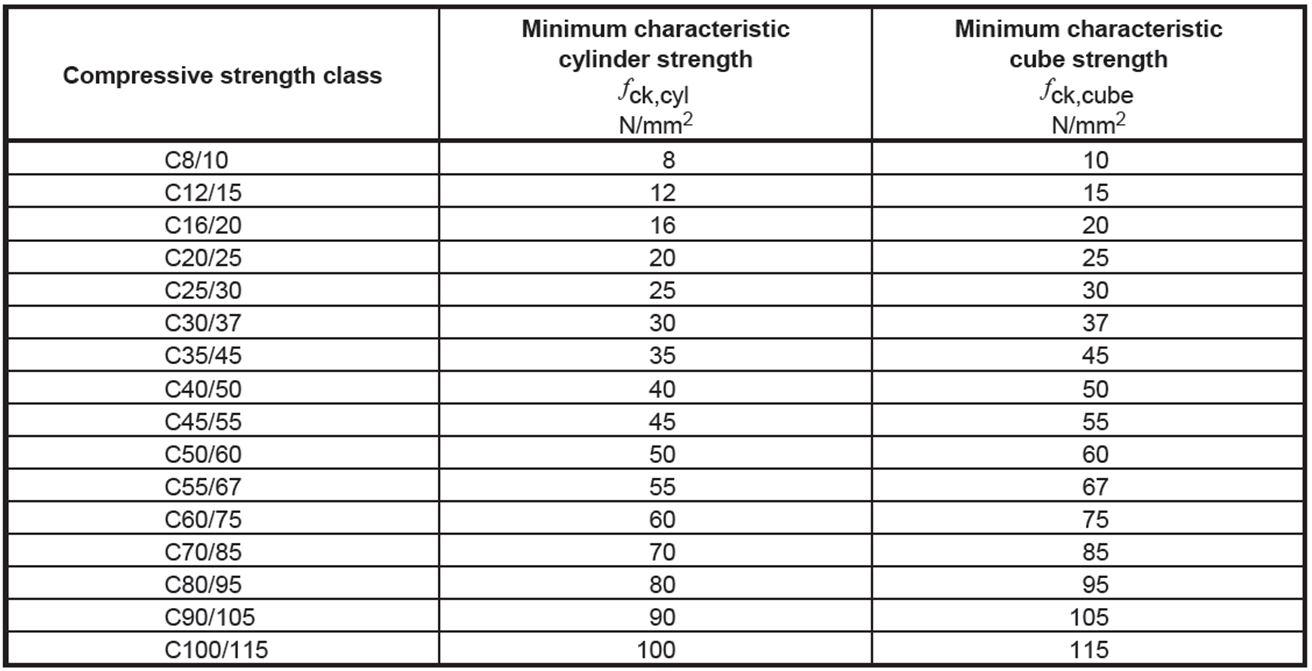

In the UK this is overcome by using two numbers to signify the concrete strength class, as shown below. The first smaller number is the cylinder strength and the second larger number is the cube strength. The prefix “C” shows that this relates to normal or heavyweight concrete. Lightweight concretes are denoted with a “LC” prefix. This is shown in the below concrete compressive strength table taken from BS EN 1992.

Factors Affecting Compressive Strength of Concrete

The compressive strength of the concrete will be affected by a number of factors;

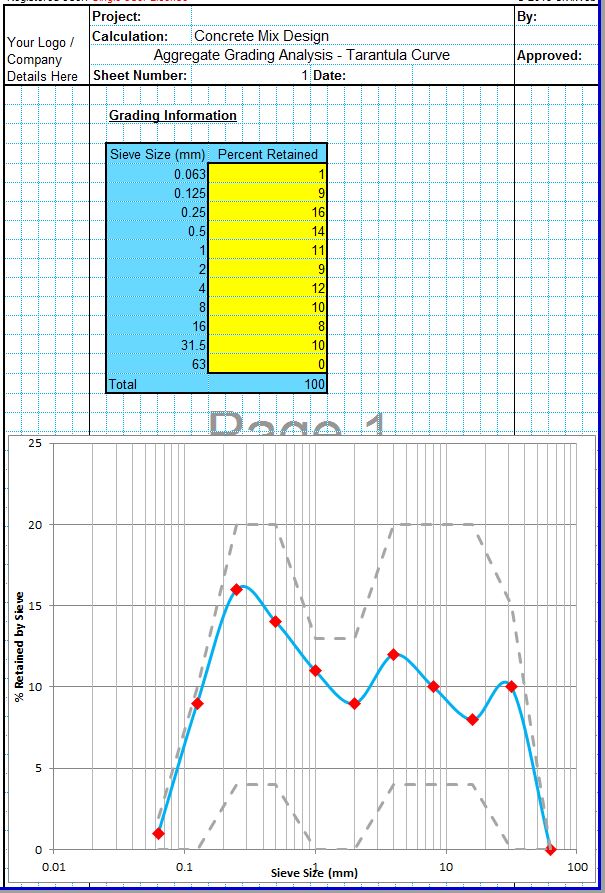

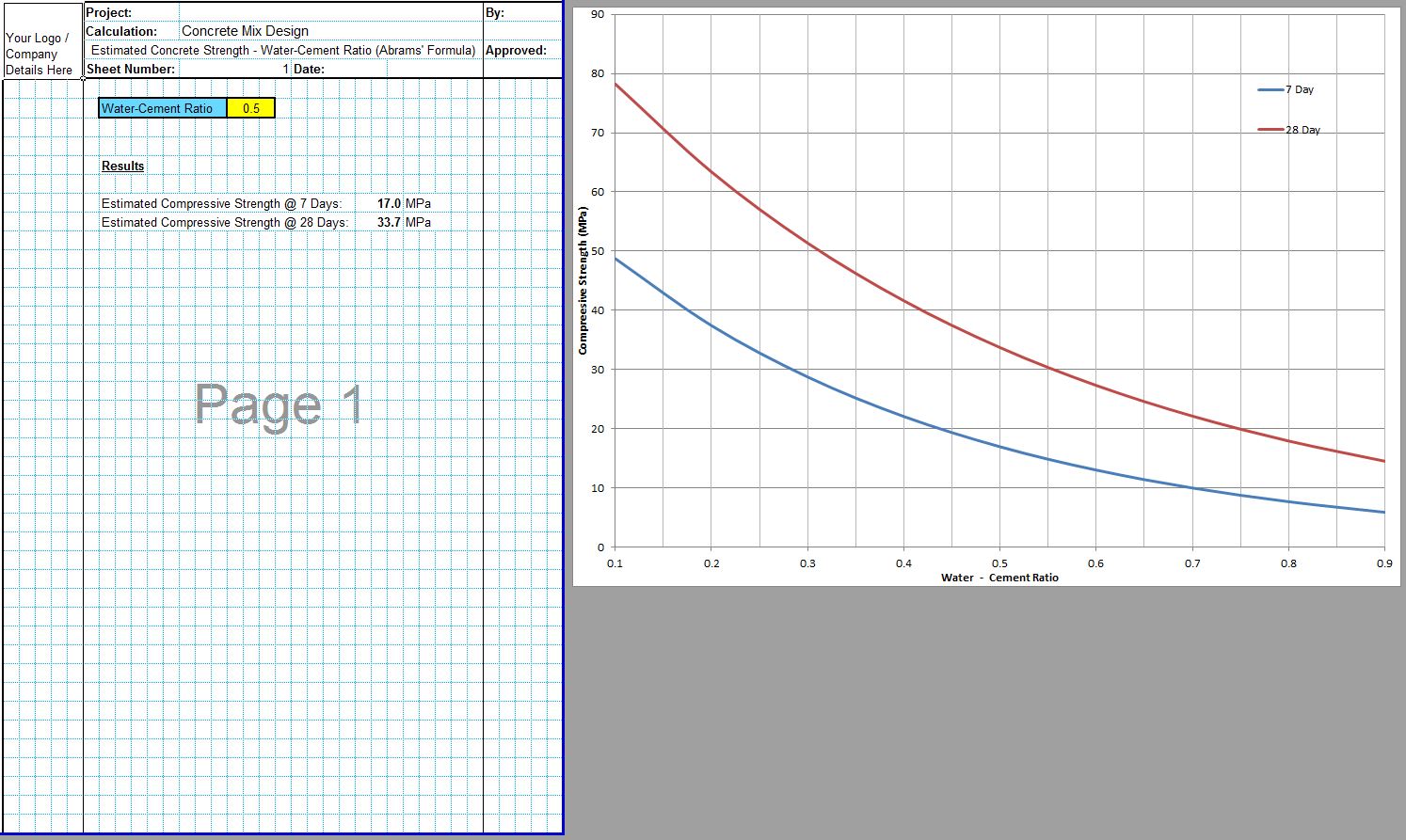

- Water-Cement Ratio – The water-cement ratio is one of the most important factors of a high strength concrete mix design. A lower water-cement ratio will generally lead to a higher compressive strength of the concrete as this will decrease the amount of free water in the mix after hydration and therefore reduce the volume of capillary pores in the hardened concrete matrix. For this reason the water-cement ratio is often limited in specifications partly to ensure the compressive strength of the concrete. Abrams’ formula can be used as a general guide to compressive strengths in normal concretes. A useful calculator tool for estimating the compressive strength of the concrete based on the water-cement ratio is included with the CivilWeb Compressive Strength of Concrete Spreadsheet. This is described in detail in our Water-Cement Ratio in Concrete post.

- Cement Type – The compressive strength of the hardened concrete can be affected by the composition, the fineness and the quantity of cement in the mix. Different cement compositions will affect the early and later age strengths as different compounds hydrate at different rates. Finer cements generally hydrate more quickly but tend to have limited later age strength development as they have a poorer quality microstructure compared with coarser cement grains.

- Supplementary Cementitious Materials (SCMs) – SCMs such as fly ash, ground granulated blast furnace slag (GGBS) or microsilica affect the strength gain of concrete in different ways. Generally fly ash and GGBS will slow the rate of hydration leading to lower early age strengths but sometimes higher later age strengths. Microsilica will increase the strength of concrete at both early age and later ages. Further information on the use of mineral admixtures for high performance concrete is included in our Supplementary Cementitious Materials post.

- Air Content – Air content directly increases the volume of voids in the concrete matrix, decreasing the compressive strength. Air content does have positive effects on the freeze-thaw resistance of the concrete so air entrainment is often used applications where the concrete is exposed to frequent freeze-thaw cycles such as concrete pavements so long as the decrease in compressive strength is allowed for in the design. Further information is included in our Air Entrained Concrete post.

- Aggregate-Paste Bond – The bond between the aggregates and the cement paste is often an important factor in the tensile and flexural strength of concrete, though is not important in determining the compressive strength.

- Workmanship – The mixing, handling and placing will affect the amount of voids in the concrete which can decrease the strength. Each of these operations must be carefully controlled to prevent poor practices from affecting the performance of the hardened concrete. This is particularly the case with the addition of water to the mix onsite to make it more workable which can have a very significant effect on the compressive strength of the concrete.

In order to perform as designed from a structural point of view, the concrete must achieve the specified characteristic compressive strength. In some cases high performance concrete can lead to problems associated with higher shrinkage and higher heat of hydration. This is particularly the case with concrete pavements where the durability of the pavement can be significantly compromised with higher shrinkage. If a high performance concrete or high strength concrete is to be used this should be checked over with the designer to ensure that there are no negative effects.

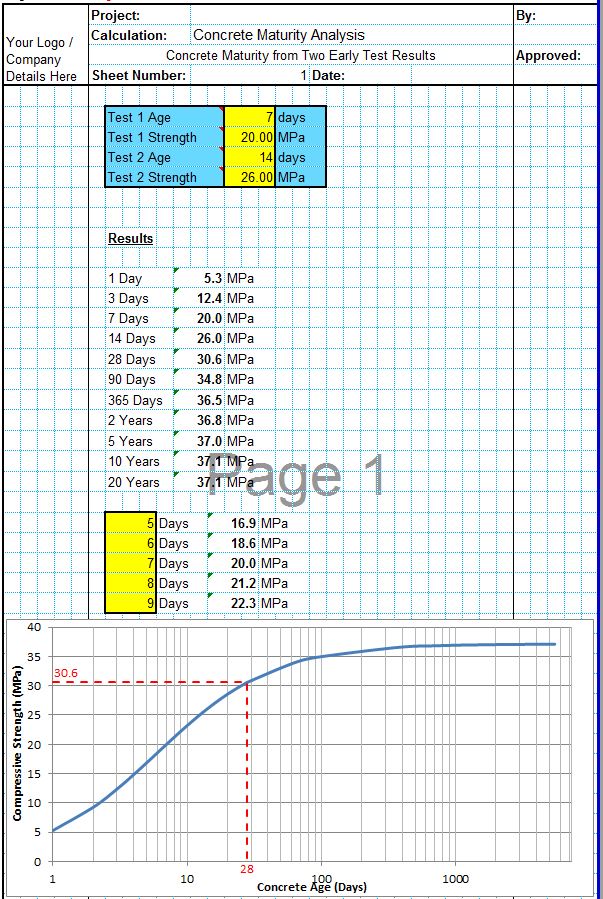

Compressive Strength of Concrete at 7 days and 28 days

Concrete continues to hydrate and to gain strength for years after it is poured. Concrete gains strength due to the chemistry of the hydration of the cement. Essentially the cement continues to hydrate while there is moisture available which it can simply take from the air in most cases. Therefore there is a problem with deciding exactly when the specified compressive strength of the concrete is required to have been achieved. A supplier could simply say wait 20 years and the concrete will be up to strength!

To get around this problem, the specified compressive strength of the concrete is taken as the 28 days strength of the concrete. Further information on the maturity of concrete is included in our Concrete Strength at 7 Days post.

CivilWeb Compressive Strength of Concrete Spreadsheet

The CivilWeb Compressive Strength of Concrete spreadsheet includes all the useful design tools detailed above. This suite of spreadsheets is available for £5 on its own, or it is included with the CivilWeb Concrete Properties Suite of Spreadsheets which is available for £10.

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.