Manning's Roughness Coefficient is a dimensionless coefficient describing the internal roughness of a drainage pipe. This value must be carefully chosen to suit the design conditions. It is dependent on mostly the same issues as the Colebrook-White roughness coefficient, primarily the pipe material and condition. Care must be taken that a conservative approach is taken for most drainage designs, as the pipe must function after 50 years of service so laboratory values for pipe materials will not be suitable for general drainage design. Some typical design values and a range for new pipes and damaged pipes are included below. Generally a conservative design value of 0.014 is often used for new drainage pipes as sliming and deterioration tend to affect all pipe materials in a similar manner.

Manning Coefficient for Partial Flow Conditions

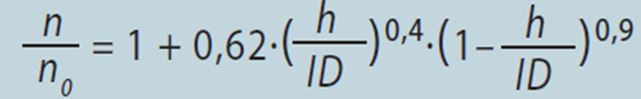

There is some evidence that the Manning coefficient should be altered for partial flow conditions. It has been proposed to use the following equation to calculate the appropriate Manning Coefficient for partial flow conditions, where ID is the internal diameter and h is the pipe fill height.

This effect can be seen in the below chart (orange line).

Typical Roughness Coefficients (n) for Manning Formula

| Manning's n Values (Pipes & Conduits) | Suggested Design Value | Likely Range | |

| Concrete Pipe | 0.014 | 0.012 | 0.016 |

| Plastic Pipe (Smooth Interior) | 0.013 | 0.009 | 0.015 |

| Plastic Pipe (Corrugated Interior) | 0.022 | 0.018 | 0.025 |

| Steel Pipe | |||

| Welded | 0.012 | 0.010 | 0.014 |

| Riveted or Spiral Steel Pipe | 0.015 | 0.013 | 0.017 |

| Corrugated Steel Pipe | 0.025 | 0.021 | 0.035 |

| Vitrified clay sewer | 0.014 | 0.011 | 0.017 |

| Brick Sewer | |||

| Glazed | 0.013 | 0.011 | 0.015 |

| Brick with Cement Mortar (Brick Sewers) | 0.015 | 0.012 | 0.017 |

| Sanitary Sewer (With Slime, Bends and Connections) | 0.013 | 0.012 | 0.016 |

| Cement Asbestos Pipe | 0.013 | 0.011 | 0.015 |

| Cast iron | |||

| Uncoated Cast Iron Pipe | 0.013 | 0.010 | 0.014 |

| Coated Cast Iron Pipe | 0.012 | 0.011 | 0.013 |

| Badly Corroded Cast Iron | 0.035 | ||

| Wrought Iron | |||

| Black | 0.014 | 0.012 | 0.015 |

| Galvanised | 0.015 | 0.013 | 0.017 |

| Ductile Iron (Cement Lined) | 0.013 | 0.012 | 0.014 |

| Smooth Brass Pipe | 0.011 | 0.009 | 0.013 |

| Smooth Glass Pipe | 0.011 | 0.009 | 0.013 |

| Wood Stave Pipe | 0.012 | 0.010 | 0.013 |

Get your copy of the CivilWeb Pipe Flow Calculator spreadsheet including full Manning Equation analysis now for only £20.

Or why not bundle the CivilWeb Pipe Flow Calculator with our Rainfall Calculator Spreadsheet for only £5 extra?

Related Spreadsheets from CivilWeb;

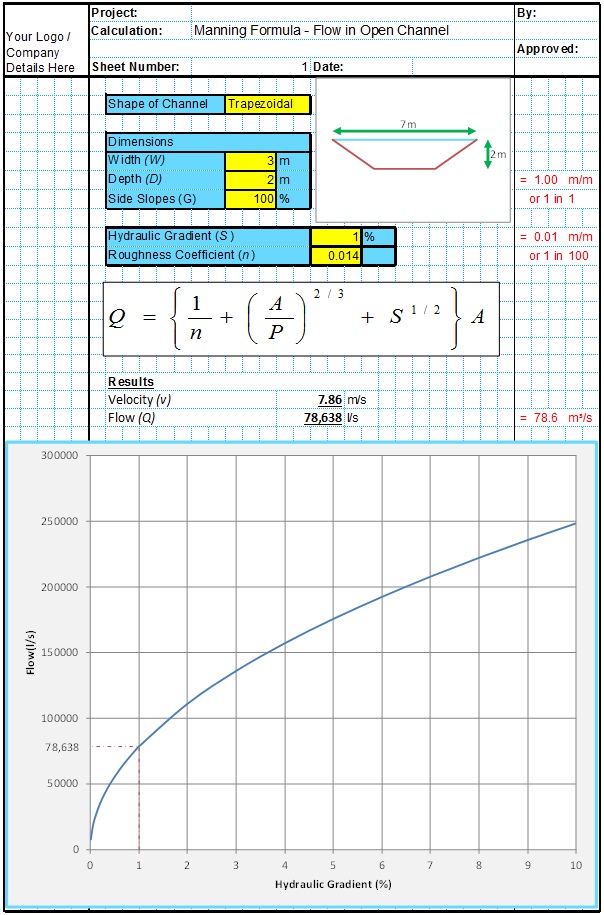

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 6 spreadsheet suites;

- Pipe Flow Calculator

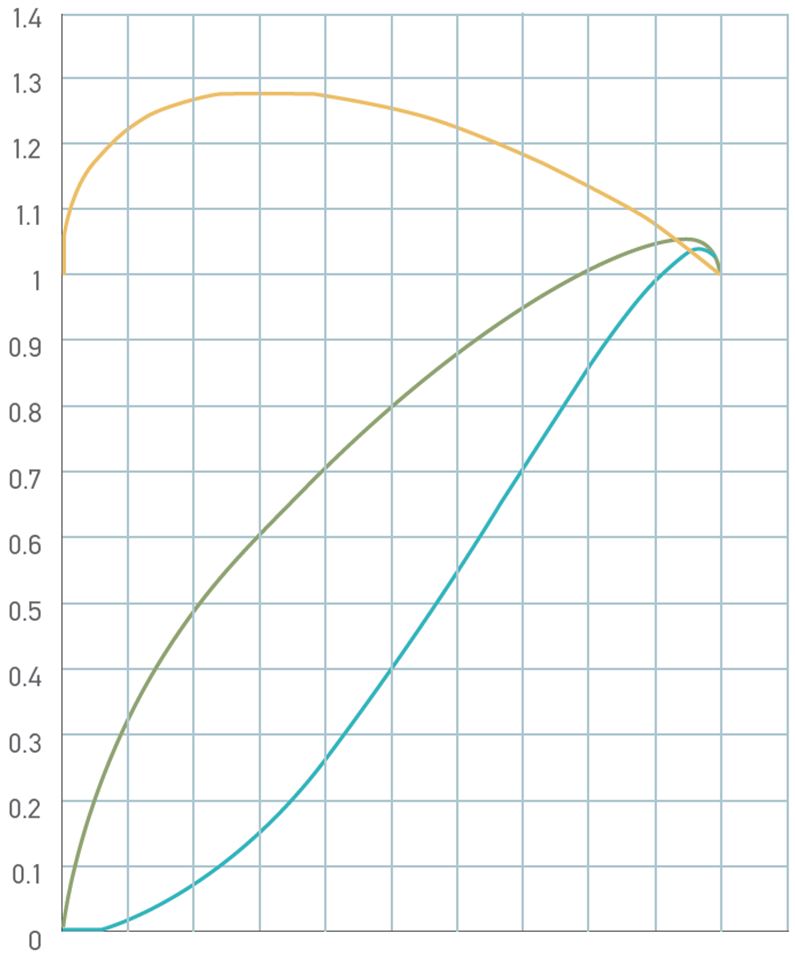

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design