A layer of geotextile soakaway membrane installed between the stone aggregate fill and the natural soils is usually required. This is to prevent fine materials from the soil from migrating into the soakaway which can cause the soakaway to become blocked and can cause settlement of the surrounding soils.

Soakaway Membranes

The geotextile membrane should not be wrapped directly around the precast concrete storage ring as this will prevent the geotextile from being cleaned or removed which it becomes blocked. The geotextile should be installed at the interface between the excavation and the surrounding natural soils.

For trench soakaways the geotextile should completely encase the backfill aggregates including the top. The geotextile soakaway membrane should include at least a 300mm overlap on top and should be placed around 200mm from the surface. The top layer should be filled with coarse aggregates similar to the backfill aggregate. This top layer can then be easily removed and replaced if it becomes clogged with sediments. This is particularly important where sheet flow is expected to flow into the trench.

There is a large variety of geotextiles soakaway membrane available. Non-woven geotextiles are generally better suited to lined soakaway applications as they contain relatively large numbers of small openings which offers a better infiltration rate than woven geotextiles.

Geotextile Membrane Selection

The following issues should be considered before the correct geotextile soakaway membrane is specified;

- Pore Size – The selected pore size should be sufficient to prevent large amounts of fine materials from the surrounding soils migrating into the lined soakaway. Similarly the pore size should prevent any sediments present in the runoff from migrating from the soakaway and blocking the pores of the surrounding soils and reducing their infiltration rate.

- Permeability – The geotextile must be at least as permeable as the surrounding soils, otherwise the geotextile will limit the natural infiltration rate of the soil and restrict the performance of the lined soakaway.

- Breakthrough Head – Some geotextiles require a head of water to be present before they become permeable and allow the water to pass through.

- Clogging Resistance – The geotextile should retain the required sediments without clogging.

- Puncture Resistance – The geotextile needs to have sufficient resistance to resist the punching stresses caused by the sharp aggregates or tree roots.

- Tensile Strength – The geotextile must be strong enough to resists any forces from imposed traffic loads.

- Chemical Tolerances – The geotextile must be resistant to any chemical or microbial effects which are expected from either the natural soils, fill materials or runoff.

- UV Tolerance – The geotextile must be sufficiently resistant to the levels of UV expected, which is typically zero.

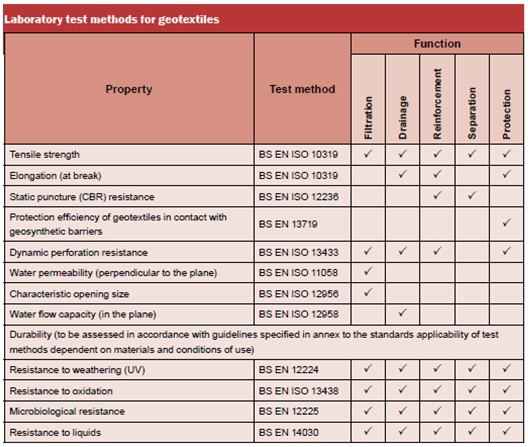

There are many standards covering the use of geotextiles. For soakaways generally BS EN 13252 should be used. A general guide to the lab tests is included below, taken from the SUDS Manual.

Special geotextiles can also sometimes be specified to prevent contaminants such as contaminated sediments or hydrocarbons in the runoff from infiltrating into the ground. Sometimes these can be installed inside the perforated precast concrete soakaway chambers if required.

Membrane Installation

The following issues should be considered when installing the geotextile;

- Care should be taken to ensure that the geotextile is stored in accordance with the manufacturer’s guidelines onsite, particularly if this is for a significant period of time. The geotextile should not be exposed to UV light fir significant periods unless it has been designed to do so.

- Care should be taken to ensure that the geotextile is not contaminated onsite, particularly with fine materials or sediments.

- It is important that there are no voids between the natural soils and the geotextile as these can reduce the infiltration rates achieved through the geotextile and promote geotextile clogging. They can also lead to settlement issues and even soil piping where the movement of water underground leads to erosion of the soils. Voids often occur where large rocks or boulders are removed from the sides of the excavation. Any voids should be filled with natural soils wherever possible. Excavated material can be used for this purpose.

- The manufacturer’s instructions should be followed when installing the geotextile. Generally it is recommended that the geotextile rolls should overlap by at least 300mm at any joints.

- The geotextile should be immediately backfilled and covered if possible. It should not be left uncovered for long periods to prevent deterioration due to UV, dust and general exposure.

Related Spreadsheets from CivilWeb;

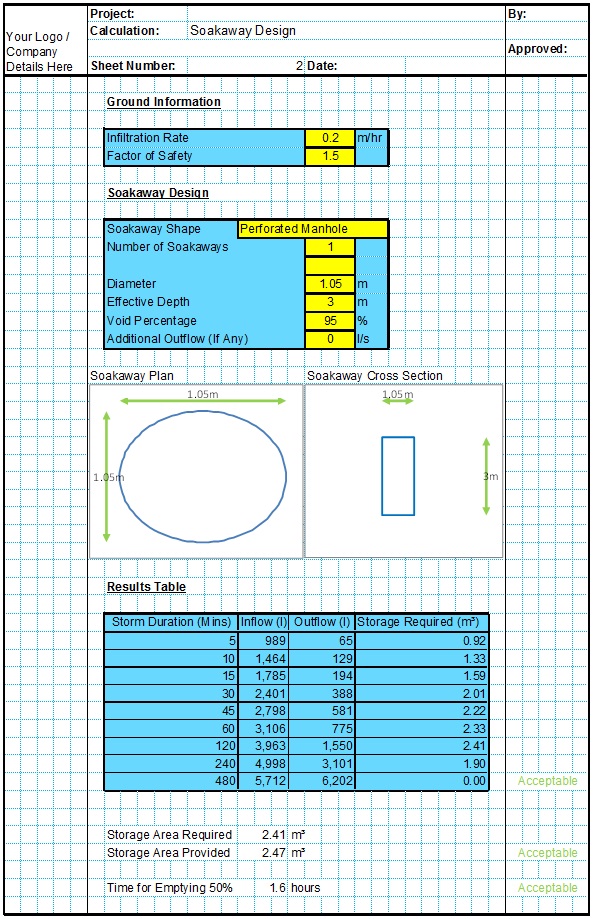

Soakaway Design Spreadsheet

This spreadsheet calculates the requirements for a soakaway system and assists the user to design a suitable system.

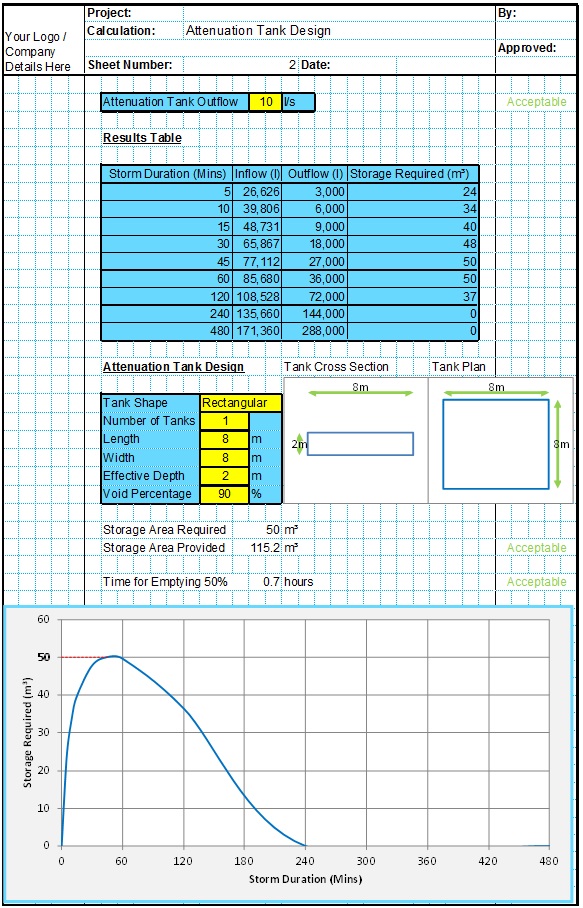

Attenuation Design Spreadsheet

This spreadsheet calculates the requirements for a attenuation system and assists the user to design a suitable system.

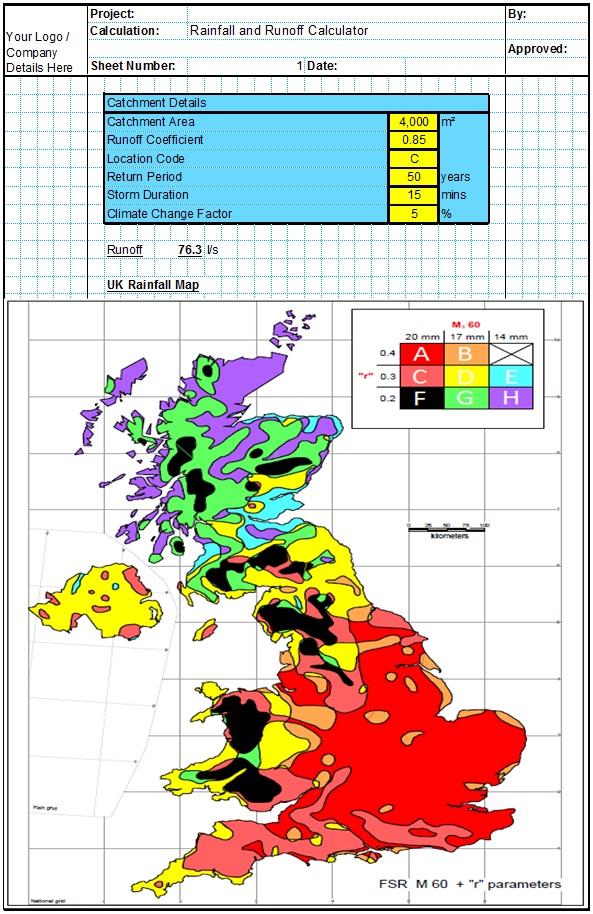

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 7 spreadsheets;

- Colebrook White Pipe Design

- Manning Pipe Design

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design