Air entrained concrete is concrete which includes a higher than normal air content. Air entrained concrete includes air entraining fibres or air entraining admixtures which capture air when the concrete is being mixed and hold it in the mix to increase the air content.

Air entrained concrete has a number of beneficial properties, mostly an increased resistance to freeze-thaw cycles. This is particularly important where the concrete is likely to be in contact with free water which can freeze such as concrete roads and pavements. The main drawback with air entrained concrete is reduced strength.

Air Entrained Concrete

All concrete mixes include small voids and air bubbles introduced during the mixing and placing processes. The size, spacing and quantity of these air bubbles has an effect on a number of the properties of both the fresh and hardened concrete.

The main benefit of small air bubbles within the mix is they increase the concrete’s resistance to freeze-thaw cycles. This is particularly important for concrete pavements in temperate regions such as the UK. The small air bubbles allow any free water within the concrete space to expand as it freezes, reducing the damage caused to the concrete. These small bubbles can be created in the concrete by the use of air entraining admixtures which capture small bubbles of air during the mixing process. Further information on air entraining agents is included in our Air Entraining Admixture post.

In the UK an air content of around 5% is specified to protect against freeze-thaw damage. Added air content will also slightly reduce the volume requirements of all the other components, slightly reducing costs.

Air Entrainment & Reduced Strength

The main downside of air entrained concrete is the air content decreases the strength of the concrete. It is questionable whether high strength, high density concrete requires air entrainment as the dense concrete does not include any water lenses to freeze.

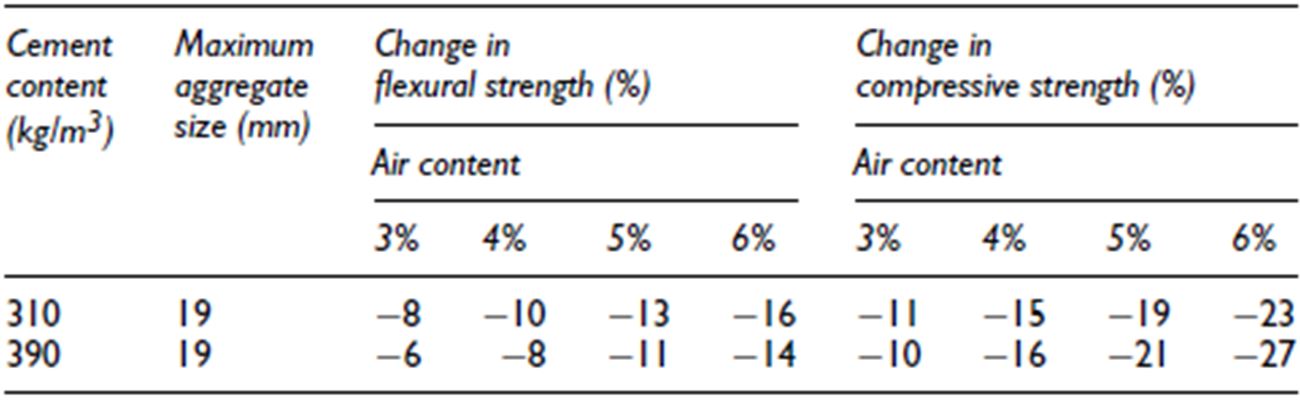

Increased air content does however increase the workability of the mix. This increased workability can then be used to reduce the water-cement ratio, partially offsetting the reduced strength. A table showing a typical reduction in strength for different air contents is shown below.

Where an air content requirement has been specified it is important that this is checked. Fresh concrete should be tested in accordance with the procedures given in BS EN 12350-7. Each concrete delivery should be tested and a tolerance of plus or minus 1.5% is often used.

Air Content in Concrete

Achieving the specified air content can be difficult as the air content of the concrete can be affected by a number of different factors. These include;

- Mix Ingredients – Any change in the type, source or quantities in any of the concrete components can have an effect on the sir content.

- Temperature – Air contents tend to reduce with any increases in concrete temperature.

- Mixing Time – The air content will tend to increase with longer mixing times up to a certain point when it will start to decrease.

- Batching Sequence – Changing the batching sequence can alter the air content of the concrete.

- Slump – More air tends to be entrained in a high slump mix than in a lower slump mix.

- Water Reducing Admixtures – Some water reducing admixtures can interact with the air entraining admixtures and reduce the effectiveness of the air entraining admixtures.

- Haul Time – In some cases longer haulage times can decrease the air content of the concrete.

- Vibration – Excessive vibration during placement can lead to lower air contents.