Air entraining admixtures are used in order to increase the air content of the concrete. Air entrained concrete have a number of benefits including higher workability and greater resistance to freeze thaw cycles. Air entraining admixtures are specified in accordance with ASTM C260 in the US.

Air Entraining Admixtures

Air entraining admixtures are used within a concrete mix to develop an entrained air void system of tiny spherical bubbles. Air entraining admixtures are typically derived from pine wood resins, vinsol resins and other synthetic detergents. The air entraining admixture captures air by creating a soap like coating. The air entraining admixture reduces the surface tension at the air-water interface stabilizing the bubbles of air within the mix. As these bubbles are formed from air added during concrete mixing, it is important that the concrete is mixed for enough time to allow the air to enter the mix and be stabilized into small bubbles.

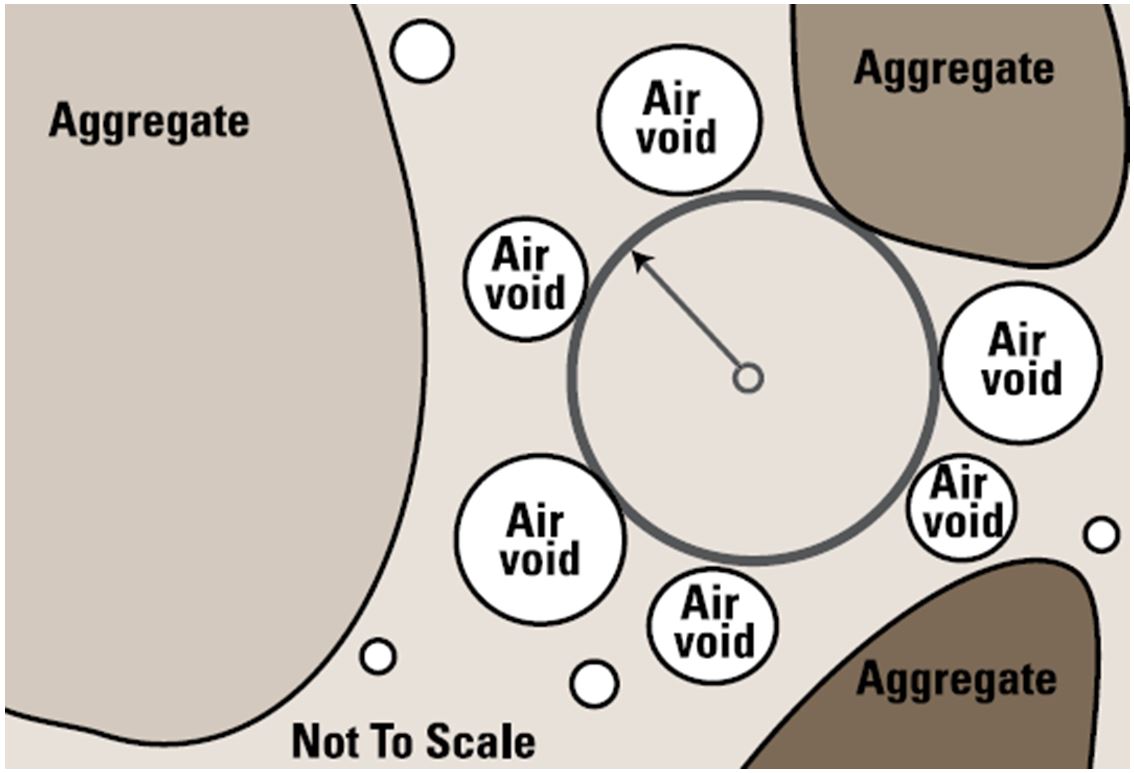

The bubbles are typically 0.05mm to 0.5mm is diameter and are spaced at a distance of less than 0.2mm. This should not be confused with entrapped air in concrete where large voids are accidentally formed during mixing and placing of the concrete. The cost of the air entraining admixture is partially offset by the reduction in the other materials required for the mix caused by the increased air content. A diagram showing the spacing of the air bubbles is shown below.

Air Entraining Agents in Concrete

This entrained air system helps to protect the concrete from damage due to freezing and thawing cycles which is an important durability parameter for most concrete pavements. The small air voids provide space for any free water in the concrete capillaries to expand into as it freezes, reducing the risk of this causing damage to the concrete. It also protects the concrete against scaling defects. Note that the entrained air will not protect newly placed concrete from frost damage before it has hardened.

The total amount of air entrained in the concrete should be between around 9% of the volume of the concrete paste to ensure adequate frost resistance. This equates to between 7.5% and 4.0% of the total concrete volume depending on the maximum size of the aggregates used, as this alters the total volume of paste in the mix. In the UK an air content of 5.0% is required for 20mm aggregates.

Air Entrainment Effects on Workability

Air entrainment also improves the workability of the fresh concrete as the spherical air bubbles help to improve workability, particularly for angular aggregates. This can be an important function as well as the freeze-thaw durability benefits of air entrained concrete. Even where freeze-thaw cycles are not expected to damage the concrete, air contents of around 3.0% are often specified just for the workability benefits.

Problems with Air Entrainment Admixtures

The air bubbles contained within air entrained concrete can also block water from bleeding to the surface of the concrete. This is usually beneficial except when the concrete is to be placed during hot or windy conditions which can lead to shrinkage cracking.

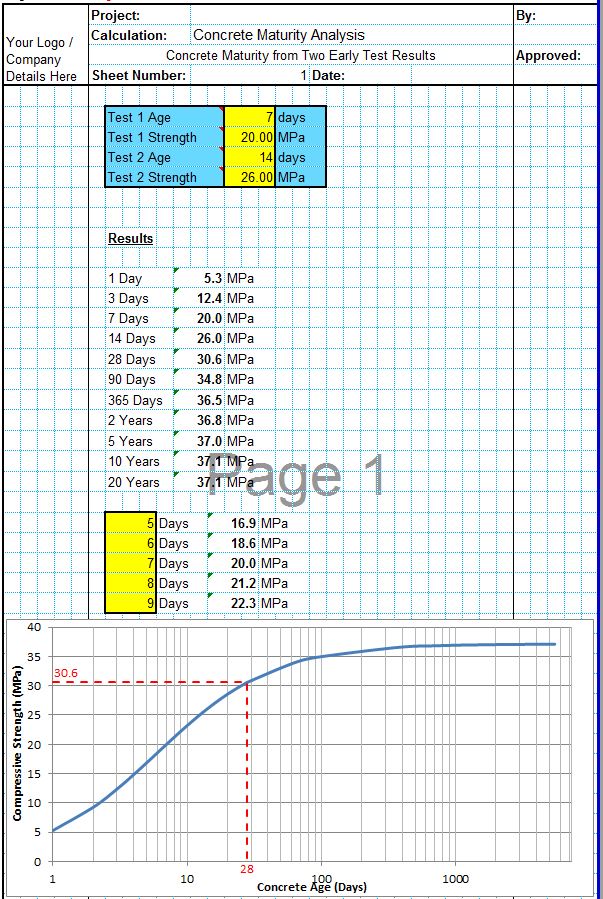

The additional air content of air entrained content does have a negative effect on the concrete strength. For each additional 1% of air content, the compressive strength of the concrete will decrease by around 5%.

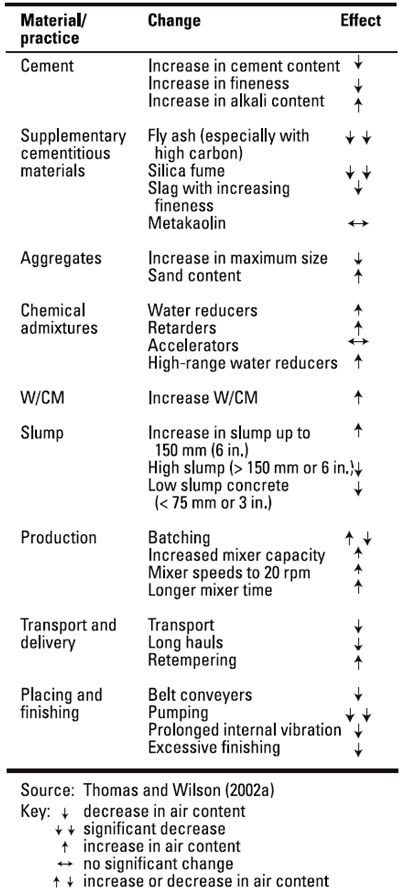

Carbon impurities within some SCMs, particularly Fly Ash and microsilica can absorb the air entrainment admixtures reducing their effectiveness. The compatibility of air entraining admixtures and any SCMs proposed for the mix should be checked. The compatibility of any water-reducing admixtures should also be checked as these can promote the formation of larger air bubbles within the mix. The effects of other mix components on the air entrainment of the concrete is summarized in the table opposite. Further information can be found in our Air Entrained Concrete post.

The table below illustrates some of the main effects of air entrainment admixtures in concrete.