Impurities such as clay in concrete can have adverse effects on the fresh and hardened concrete. Any silts or clays contained within the aggregates will increase the water demand of the mix due to the relatively high surface area of the fine silt or clay particles.

Clay in Concrete

Clay in concrete will also reduce the bond strength between the aggregate particles and the cement paste when the fine silt or clay particles form a thin coating on the aggregate particles. Any clay agglomerates contained within the aggregates will absorb some of the water during mixing and can cause popouts in the concrete surface as the clay dries out.

Some specifications limit the amount of silt or clay particles within the aggregates to a maximum of 5% of the aggregate mass, though much lower quantities should be achievable through proper controls at the aggregate source. A maximum value of around 2% is often specified.

Minimizing Clay in Concrete

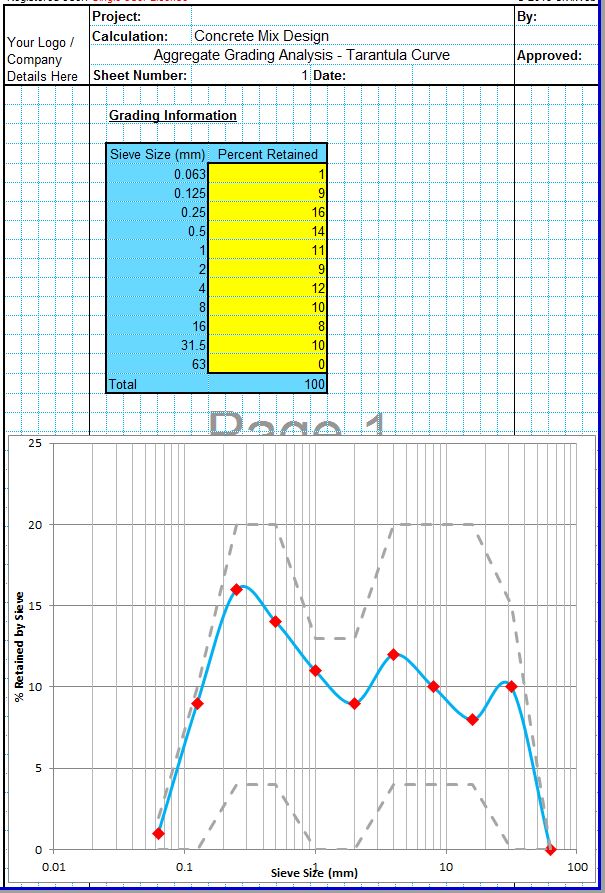

One common method of control is to limit the maximum percentage of fine aggregate particles which pass the 63μm sieve. In natural fine aggregates and aggregates produced from crushing natural gravels it is likely that many of these particles will be clay. By limiting the fine content this can minimize the risk of significant volumes of clay entering the concrete mix.

Fine aggregates produced from crushed rock or sand do not require such controls as the fine particles in these cases are unlikely to be clay.