Anchor Bolt Pullout Strength describes the anchors resistance to bolt pullout failure. The CivilWeb Concrete Anchorage Design Spreadsheet calculates the anchor bolt pullout strength in accordance with BS EN 1992-4 as part of a full design procedure for anchorages in concrete.

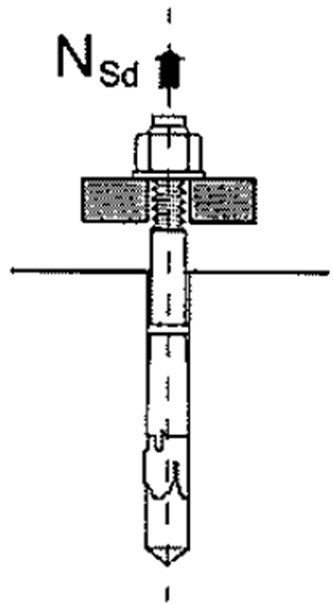

Bolt pullout failure can occur in either cast in anchors or mechanical anchors. For cast in fasteners this occurs when the bond between the concrete and the anchor bolt fails and the bolt is pulled out of the concrete. Note this is not a concrete cone failure of the concrete, but a failure of the bond. For mechanical fasteners this occurs when the mechanical device fails and allows the bolt to be pulled out of the concrete.

Anchor Bolt Pullout Strength - Cast In Bolts

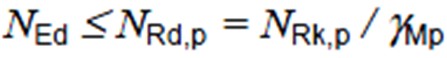

For cast in anchors the Design Pull Out Resistance (NRd,p) must be greater than the tensile force (NEd) as shown below.

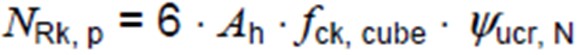

Characteristic Pull Out Resistance (NRk,p)

This is limited by the concrete pressure under the head of the bolt. This can be calculated using the below equation;

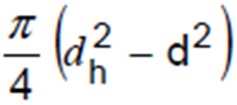

Head Load Bearing Area (Ah)

This can be calculated from the dimensions of the head and bolt.

Diameter of the Anchor Head (dh), Diameter of the Bolt (d)

These can be taken from the manufacturer’s info.

Characteristic Cube Strength of Concrete (fck,cube)

This can be taken from tests taken during the concrete pour or from design info.

Ψucr,N

This depends on whether the concrete is cracked or not. For uncracked concrete Ψucr,N = 1.4, for cracked concrete Ψucr,N = 1.0. The definition of cracked and uncracked concrete is explained here.

Partial Safety Factor for Bolt Pull Out Failure (γMp)

This is the partial factor used for all concrete failures. This is described in detail here.

Design Verification Calculations - Mechanical Anchors

For mechanical anchors the Pull Out Resistance (NRd,p) must be greater than the tensile force (NEd) as shown below.

Characteristic Pull Out Resistance (NRk,p)

The Characteristic Pull Out Resistance value for the fastener will be given by the manufacturer.

Partial Safety Factor for Bolt Pull Out Failure (γMp)

This partial safety factor is calculated using the below formula which depends on the quality of the installation.

Partial Safety Factor for Concrete (γc)

This is detailed here. A value of 1.5 is typically recommended.

The CivilWeb Concrete Anchorage Design Spreadsheet completes the above detailed calculations and presents the results along with a series of design graphs showing the designer the sensitivities of the key design parameters as well as whether the proposed anchorage is acceptable in accordance with BS EN 1992-4.

Get your copy of the CivilWeb Concrete Anchorage Design Spreadsheet now for only £20.

Download Free Trial Version

To try out a fully functional free trail version of this software, please Click Here or enter your email address below to sign up to our newsletter.