The flakiness index is used to describe the average particle shape of aggregates including those used for concrete. A high flakiness index test result indicates a high proportion of elongated aggregates, a low test result indicates a low proportion of elongated aggregates.

Elongated Aggregates

Elongated aggregates are defined as those with a ratio of width to thickness greater than 3. Elongated aggregate particles are not desirable as they will lead to increased water demand to produce workable concrete and the elongated aggregate shape often indicates that the particle has weak fracture planes which can affect the strength of the concrete. Elongated aggregate particles can also increase the risk of segregation during handling and placing the concrete and can be more difficult to pump.

In the UK the quantity of flat or elongated particles is called flakiness. The flakiness of the aggregates can be determined using a flakiness index test as detailed in BS EN 933-3. This test is also sometimes referred to as a shape test of the aggregate, an aggregate flakiness test or aggregate elongation test.

Flakiness Index Test

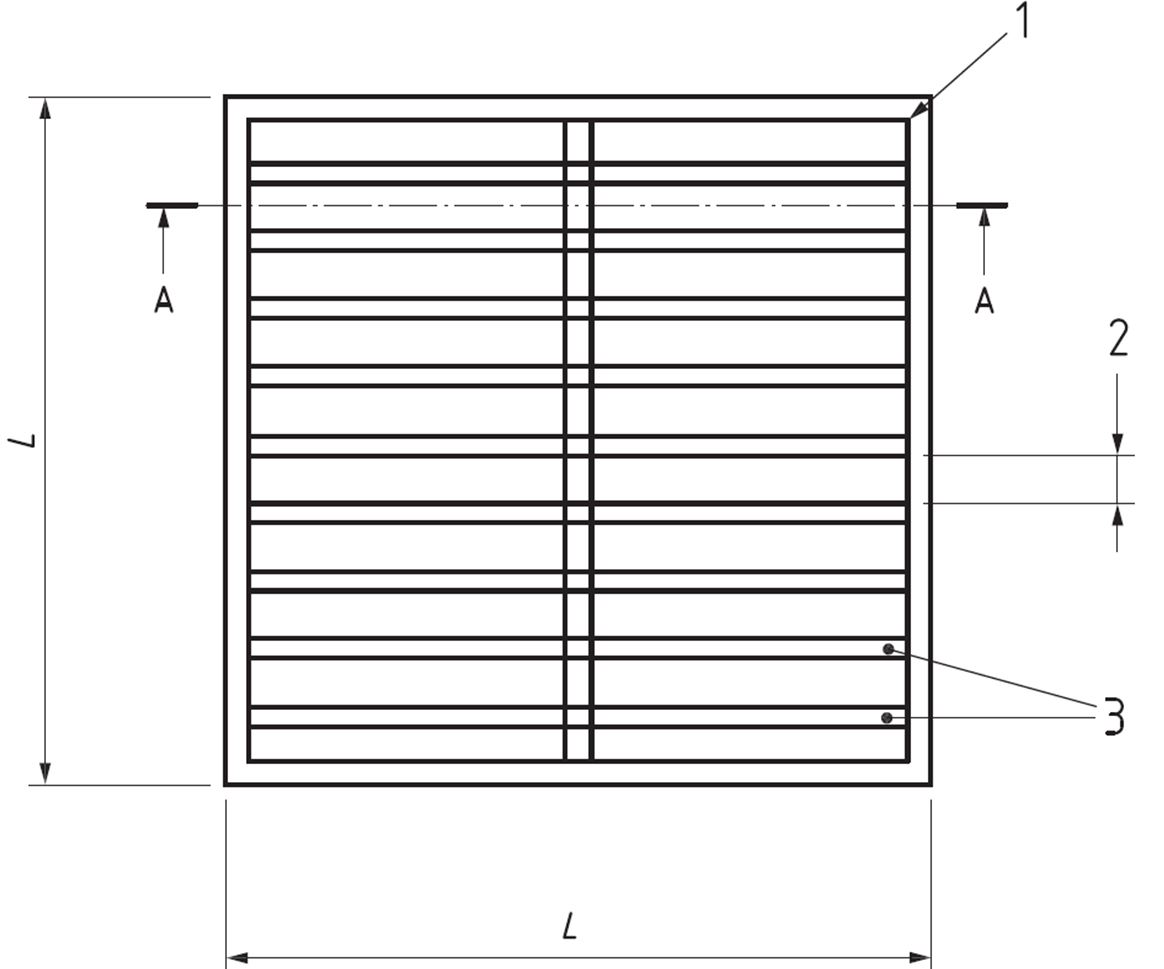

The elongation and flakiness test involves sieving the aggregates through a sieve with long parallel openings (as shown in the diagram below) which measures the amount of aggregates which are elongated which determines the flakiness index. Many specifications state a maximum flakiness index test value of around 35, though lower values of 30 or even 25 are often specified where the water content of the concrete needs to be controlled for workability or strength reasons.

Shape of Aggregate in Concrete

The angularity, elongation and flakiness and shape of coarse aggregates in concrete is determined by the source and method of production of the aggregate. Marine aggregates dredged from rivers will naturally have a spherical, smooth, rounded shape due to the natural processes of erosion. Conversely aggregates manufactured from crushed rock will be more of a cubical shape, rough texture and will contain sharp edges and angular corners. These different types of aggregate are illustrated in the images below.

The shape of the aggregates in concrete has a number of effects on the concrete’s properties. Rounded aggregates are more workable as the rounded shape offers a lower surface area than more angular aggregates. This reduces the amount of paste required to coat the aggregates, increasing workability and reducing water and cement requirements. The reduced cement content will also reduce the shrinkage of the concrete and make the concrete more economical. Increased workability also makes the fresh concrete easier to pump and to finish.

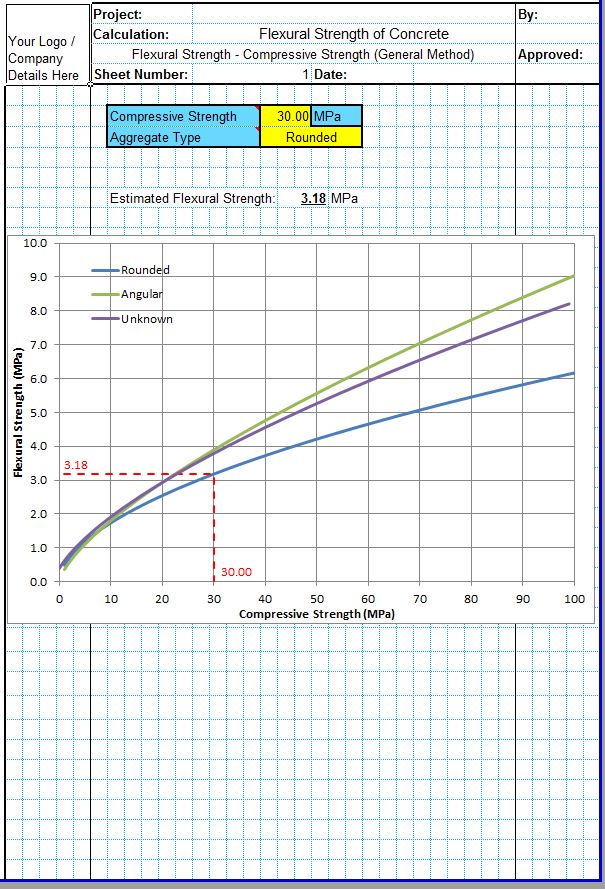

Angular aggregates require more paste, and are therefore less workable than rounded aggregates. This effect is particularly significant with crushed fine aggregates. They will however produce greater aggregate interlock due to their sharp corners which increases the strength of the concrete, particularly the flexural strength. The rough texture of angular aggregates also leads to greater bond strength between the hardened cement paste and the aggregates, which increases both compressive and flexural strength. Angular aggregates in some cases can also be more difficult to pump.

CivilWeb Aggregate Grading in Concrete Analysis Spreadsheet

Buy now for only £5.

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.