The grading of fine aggregate has a significant effect on the workability of the concrete mix. The Fineness Modulus is used in US practice and is a measure of the grading of fine aggregates. It can be calculated from a sieve analysis by adding the cumulative percentages of fine aggregates retained on the following sieve sizes; 0.15mm, 0.30mm, 0.60mm, 1.18mm, 2.36mm and 4.75m. This value is then divided by 100 to give the fineness modulus. A Fineness Modulus calculator tool is included in the CivilWeb Grading of Aggregates on Concrete spreadsheet.

Grading of Fine Aggregates - US

The fineness modulus must be between 2.30 and 3.10 to meet the requirements of US standard ASTM C33. This effectively sets grading limits for fine aggregates. The grading zone of fine aggregates is limited to those with a finenesss modulus of between 2.30 and 3.10.

A high fineness modulus generally indicates that the aggregate is deficient in smaller particles. Fine aggregate gradings with higher fineness modulus values are also cost effective as the coarse particles will reduce the water requirement and therefore the cement required for the concrete mix.

The fineness modulus is used in concrete mix design to indicate the effects of the fine aggregates on the workability of the mix. The measured fineness modulus of fine aggregates provided by the supplier should not deviate from the value used in design by more than 0.20. If the fineness deviates by more than 0.20 the concrete mix may need to be redesigned. This is particularly important in slipformed pavements, pumped concrete or other methods where the workability of the mix is critical.

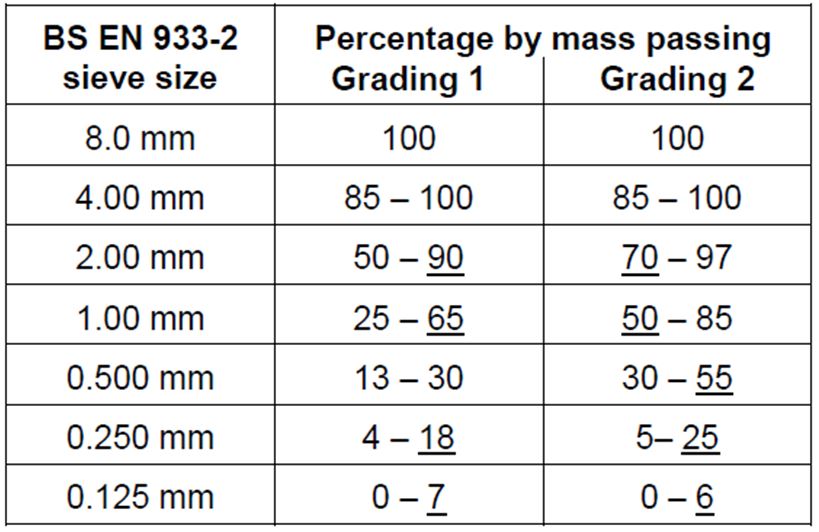

Grading of Fine Aggregates - UK

In the UK the following grading of fine aggregates are often used. A total tolerance of around 5% is often applied to these percentages to account for minor deviations. Also the percentage passing the 0.125mm sieve can be increased to around 15% if manufactured fine aggregates are used.

Grading of Fine Aggregates – Testing Methods

Testing is recommended to check the consistency of the grading of the fine aggregates at the supply site and onsite during production. It is recommended that the fine aggregate gradings are tested every day during production. This sampling and testing should be completed in accordance with BS EN 932 and BS EN 933.

If the contractor wishes to deviate from the agreed grading of the fine aggregates to suit locally available aggregate supplies for example, this can often be accommodated. In this case the contractor or supplier must be able to demonstrate that the proposed grading of the fine aggregates will meet the performance requirements of the specification. This is often done with evidence of past uses of the gradation or for a new grading can be demonstrated by testing on a trial area of pavement.

Total Fine Aggregate Content

As well as the grading of the fine aggregates, the total fine aggregate content must also be considered. Fine aggregates in the concrete mix have a large surface area and therefore a high water demand. For this reason the fine aggregate content of the concrete mix needs to be controlled in order to control the workability of the fresh concrete.

Generally the total fine aggregate content passing the 2.0mm sieve should be between 30%-40% of the total aggregate content. This is to ensure that the mix will be sufficiently workable. Less fine aggregates can generally be specified for low slump concrete as this concrete is not susceptible to segregation and does not bleed excessively.

For a concrete mix with a low workability requirement, for example those to be installed using a slipform paver or mechanical finishing, a fine aggregate content of around 5%-10% passing the 300μm sieve is generally suitable. For pavements or other concrete which will be hand finished a fines content of more than 15% passing the 300μm sieve will be required.

Minimizing Clay Content of Fine Aggregates

For uncrushed fine aggregates or fines manufactured from crushed gravel the maximum amount of fine materials passing the 63μm sieve should not exceed around 3% of the total aggregates. This is due to the likelihood of many of these particles to be clay which will reduce the strength and increase the water requirements of the concrete. Further information is included in our Clay in Concrete post.

Where manufactured fine materials made by crushing rock or sand are to be used the maximum fines content can be increased as these particles will be largely free from clay or shale and will not be soft. The amount of fine materials passing the 63μm sieve in this case should not exceed 9%.

Minimum Fine Aggregate Content

In addition to the maximum values, a minimum value of fine materials is also required to prevent excessive bleeding, which can lead to further restrictions on the water content of the mix. A minimum value of around 2-3% passing the 150μm sieve is often recommended, particularly for hand laid or hand finished pavements. Less fine aggregates are generally required in air entrained mixtures, and any deficiencies in fine aggregates can be offset with the use of fine supplementary cementitious materials.

As well as the workability, the fines content also affects the abrasive resistance of the finished concrete. Where abrasive resistance is important fine aggregates should not contain any larger friable particles which may break down under mechanical actions. This is important as fine aggregates are present at the concrete surface and should be sufficiently strong to resist the expected mechanical actions. This is particularly important where a concrete pavement will be utilized for hard wheeled vehicles or for shovel loaders handling bulk materials, or where erosion or other abrasive effects are expected.

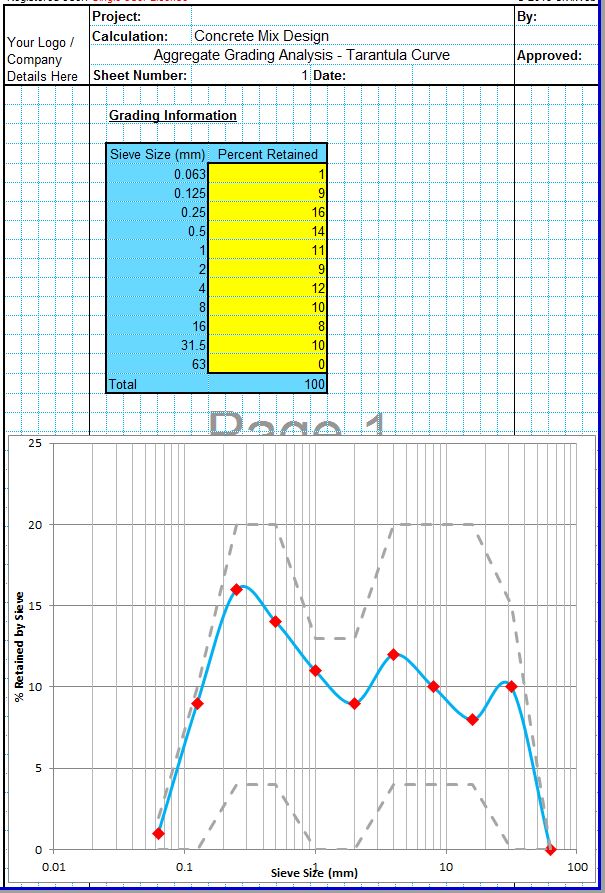

Grading of Aggregates in Concrete Analysis Spreadsheet

The grading of the fine aggregates must be compatible with the grading of the coarse aggregates. This ensures that the combined grading of the aggregates will be suitable. Further information is included in our Grading of Aggregates in Concrete post.

The CivilWeb Grading of Aggregates in Concrete Analysis spreadsheet is available for purchase below for just £5. The tool is also included with the Concrete Properties Suite which costs just £10.

CivilWeb Grading of Aggregates in Concrete Analysis Spreadsheet

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.