The quality of water for concrete is important to ensure that no deleterious contaminants enter the mix with the mixing water. In general clean potable water will always be suitable for concrete mixes. Recylced or grey water can be acceptable so long as the water is tested and controlled to prevent chlorides, sulphates or other harmful additives from entering the mix. Saltwater can also be used in some cases for unreinforced concretes.

Quality of Water for Concrete

Water is an essential component of all concrete mixes but it does not vary very much and therefore the quality of mixing water in concrete does not get much attention. Water is required for the hydration of the cement and for the workability of the fresh concrete. The mixing water required for concrete pavements does not differ from the requirements for any concrete and should conform with BS EN 1008.

Water Standards for Concrete

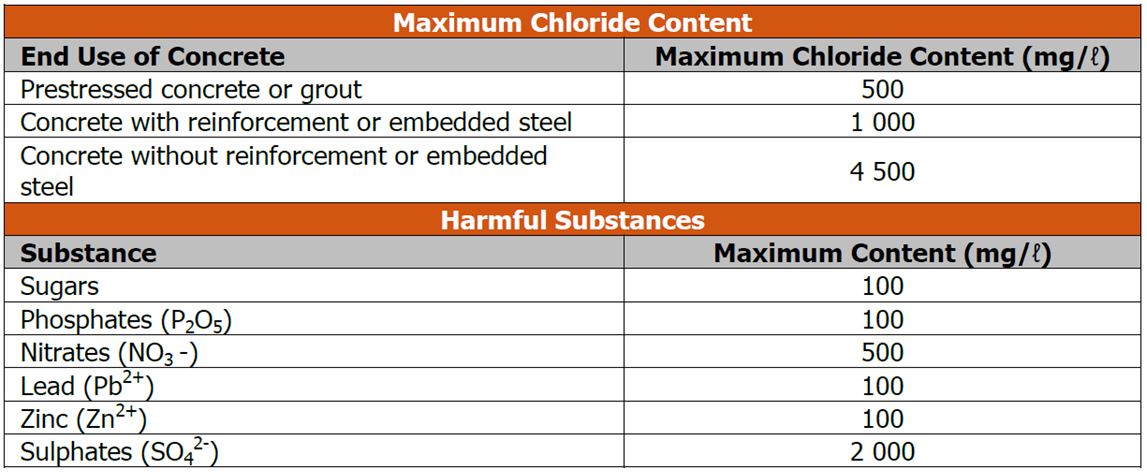

Mixing water must be free of any significant quantities of oils, salt, acids, alkalis, vegetable matter, sugars or any other substances which will be harmful to the concrete or affect the hydration of the cement. Excessive impurities in the mixing water can affect the setting time of the fresh concrete and the strength of the hardened concrete. Any moisture or water coming from the aggregates must also be suitably free of contamination, and must be tested if there is any doubt. Some of the requirements detailed in BS EN 1008 are shown in the table below.

Potable Water Quality for Concrete Mixes

Clean potable water will always be of suitable quality for mixing concrete. If clean potable water is not available or the quality of the water is in doubt, the water should be tested in accordance with the requirements of BS EN 1008. This will include the testing of the water for;

- Chloride content

- Sulfate content

- Alkali content (particularly where alkali reactive aggregates may be used)

- pH

- Harmful contaminants including sugar, phosphates, nitrates, lead and zinc

- Setting time of fresh concrete made with the water

- Strength of hardened concrete made with the water

Quality of Water in Concrete - Natural Water Sources

Water can be taken from natural sources as long as the requirements of BS EN 1008 are met. This means that natural sources of water must be obtained in a manner which excludes silts, mud, grass or other foreign materials.

Quality of Recycled Water Used in Concrete

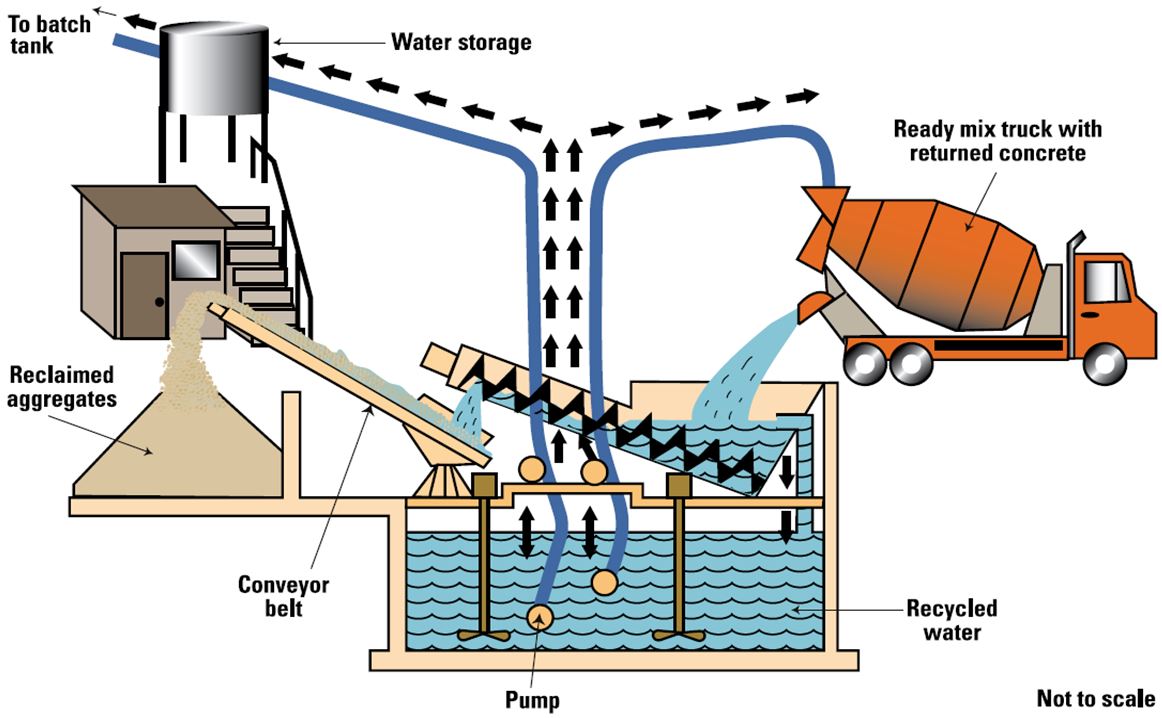

Water recycled from the processing of returned concrete, wash water and rain water harvested at the concrete plant can be used as mixing water so long as it meets the requirements of BS EN 1008. One method of reclaiming water and aggregates from returned concrete is shown in the below diagram.

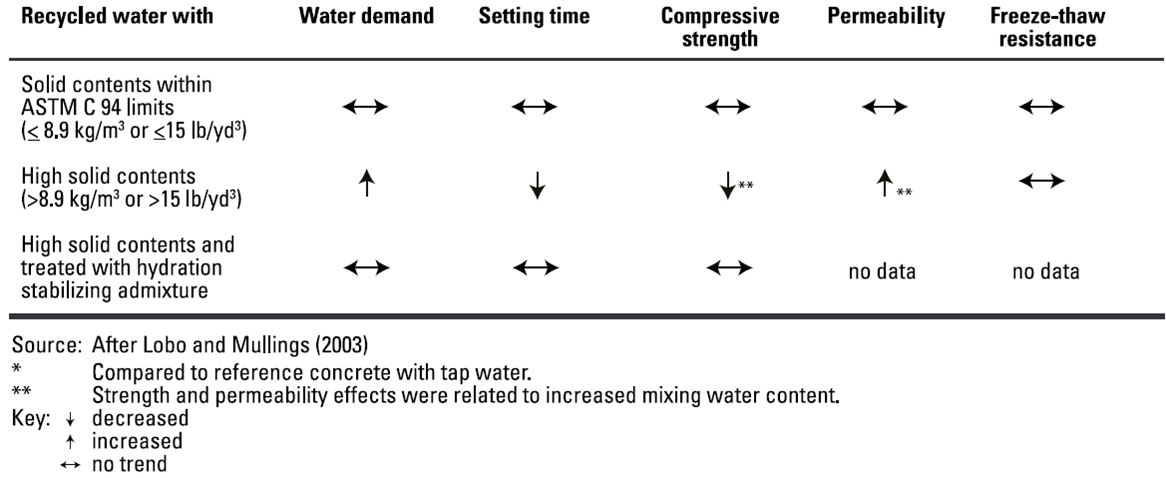

The recycled water is often processed through settling ponds or similar sediment control methods. Any recycled water used for making concrete must be tested regularly to make sure that it meets the requirements and the water quality does not deteriorate over time or between sources. Using recycled water will typically have an effect on the properties of the concrete, as shown in the below table.

Saltwater in Concrete

In some places fresh water is in limited supply which makes it more expensive or difficult to use large quantities of potable water for making concrete. Seawater or other salt water sources can be used for concrete but they will introduce too many chlorides into the concrete which will accelerate the corrosion of any reinforcing steel, dowels or other embedded steel items. Seawater can however be used in unreinforced concrete and where the reinforcement and dowels are suitably protected from corrosion, for example by using coated steel. Using salt water to make concrete can reduce the strength of the hardened concrete by as much as 15% and can affect the setting time. Concrete utilising salt water will also show signs of efflorescence and salt deposits on the concrete surface. This is a purely aesthetic concern and will not harm the performance or the durability of the concrete.

Temperature of Mixing Water

The temperature of the mixing water has a large effect on the temperature of the fresh and hydrating concrete. This is because water has a much higher specific heat capacity than the other main components of concrete (aggregates or cement). When there are temperature concerns one way to mitigate the effects is to alter the mixing water temperature. In cold climates mixing water is often heated to prevent the fresh concrete from freezing during and shortly after placement. Similarly in hot climates concrete is often mixed with chilled water or even ice to limit the temperature of the fresh concrete. Any ice added to the mix must be completely melted and mixed in before the mixing process in complete.