Recycled concrete aggregates are being used more and more as the drive for more environmentally friendly concrete increases along with the costs to dispose of unwanted concrete.

In principle the requirements for recycled aggregates used in concrete works are the same as for any natural or manufactured aggregates. The benefits of using recycled concrete aggregates on a project include reduced material and haulage costs for the new concrete and reduced disposal costs for any old concrete. It also conserves natural aggregate sources and saves the energy of extracting and processing natural and manufactured aggregates.

Recycling Concrete into Aggregates

It is very important that the process of recycling the concrete into aggregates is carefully controlled to ensure that all deleterious materials such as reinforcing steel and other embedded items, wood and soil are removed. The broken concrete lumps can then be crushed into new aggregates. Care needs to be taken that the recycled aggregates are clean and free of chemicals, coatings, clay and other contaminants. Ideally the source of the aggregates should be known.

Recycled Concrete Aggregates

The sulfate and chloride content of the aggregates should be checked prior to use, and the aggregates contained in the existing concrete should not be susceptible to alkali-aggregate reactions. If the existing concrete was suffering from alkali-aggregate reaction the concrete can be recycled but care must be taken to ensure that the new concrete mix includes supplementary cementitious materials to mitigate the alkali-aggregate reaction. Also any concrete pavements which suffered from D cracking can also be recycled but must be crushed to a smaller aggregate size to protect the new slab from similar D cracking.

The particle shape of recycled concrete aggregates is usually similar to the angular shape of crushed rock aggregates. In some cases the crushing process can remove most of the mortar from rounded marine aggregates, producing a product similar to the original natural aggregate. The specific gravity of the recycled aggregates tends to decrease as the particle size decreases, but this is not usually a concern for concrete projects. The abrasive resistance of recycled concrete aggregates is typically very good.

Recycled concrete aggregates can produce concrete of similar strength, workability and durability as normally sourced aggregate concrete. The concrete will have a similar permeability as concrete made with conventional aggregates and the frost and carbonation resistance will be similar.

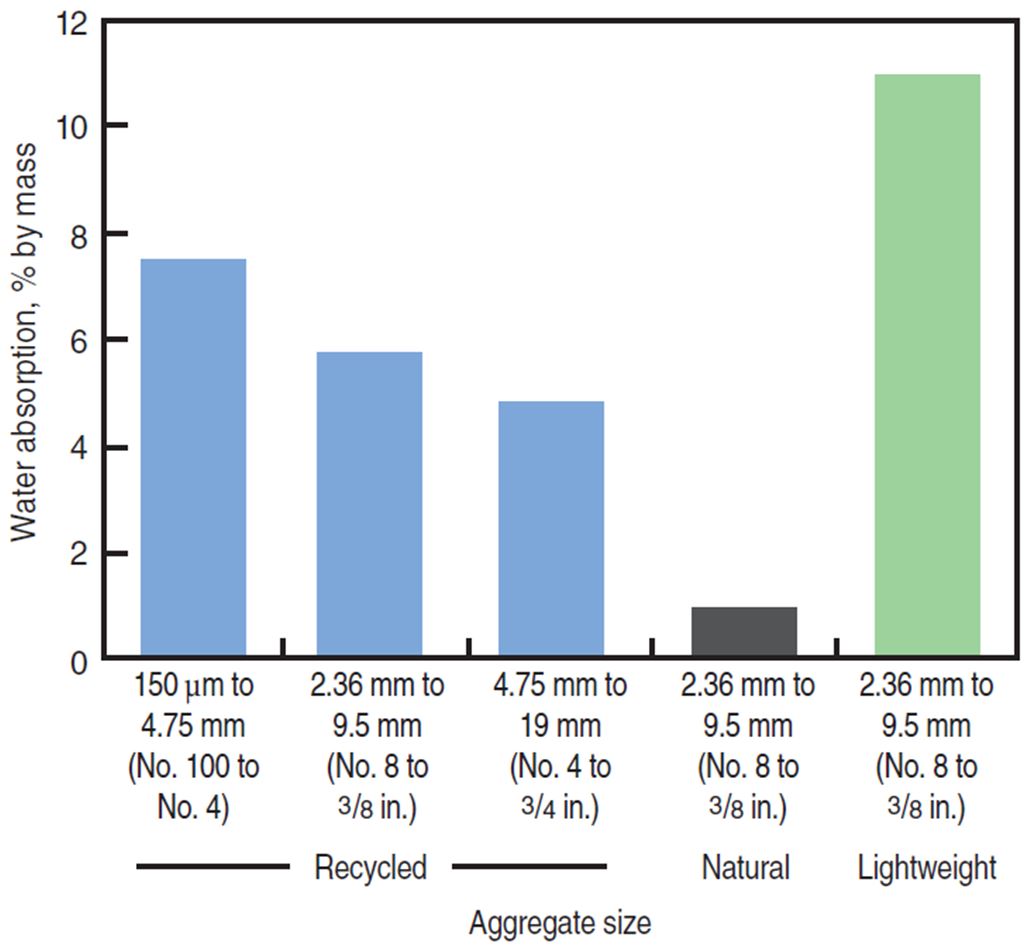

Water Absorption of Recycled Concrete Aggregates

Crushed recycled concrete aggregate will generally have a lower specific gravity and higher absorption value than other aggregates. The higher absorption is due to the porosity of the hardened cement paste. Typical absorption values of between 3% and 10% can be expected and this can be measured and allowed for in the mix design to achieve suitable workability. The moisture content of the recycled aggregates should be monitored carefully and recycled aggregate stockpiles can be pre-wetted and kept moist to prevent them from absorbing mixing water. Typical absorption values are shown in the below graph.

Recycled Concrete Fine Aggregates

Recycled concrete aggregates are usually only used as coarse aggregates, with natural sand used for fine aggregates. Drying shrinkage and creep can be increased by up to 100% in concretes utilizing more than around 10% to 20% recycled fine aggregates. This is due to the large quantities of existing cement paste included with the recycled fine aggregates and a higher coefficient of thermal expansion compared with conventional aggregates. This increased shrinkage and creep can be mitigated by using the Equivalent Mortar Volume method of proportioning the mix. This involves including the volume of mortar expected in the recycled aggregates with the total mortar content rather than treating it as aggregate. The volume of mortar in the aggregates must be tested for an accurate value. This can reduce the shrinkage and creep expected back to the same levels as conventional concrete.

If recycled fine aggregates are used there is also usually a small decrease in compressive strengths, tensile strengths and the elastic modulus of the hardened concrete. Flexural strengths can be reduced by up to 25% if recycled concrete aggregates are used for all the coarse and fine aggregates. This can be mitigated by increasing the cement content of the mix if required. Indeed some recycled concrete aggregate projects have reported an increased early age strength as the newly exposed cement particles in the aggregates are able to hydrate.

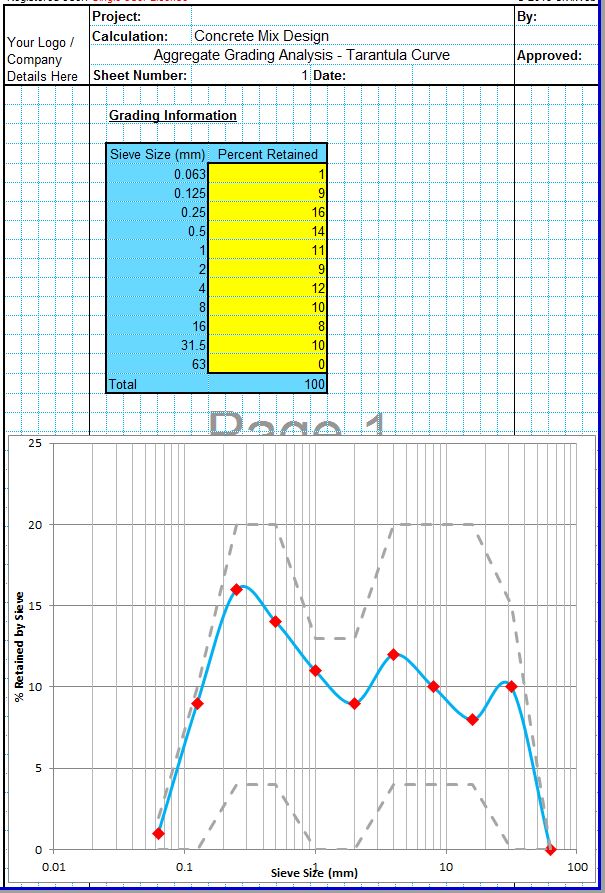

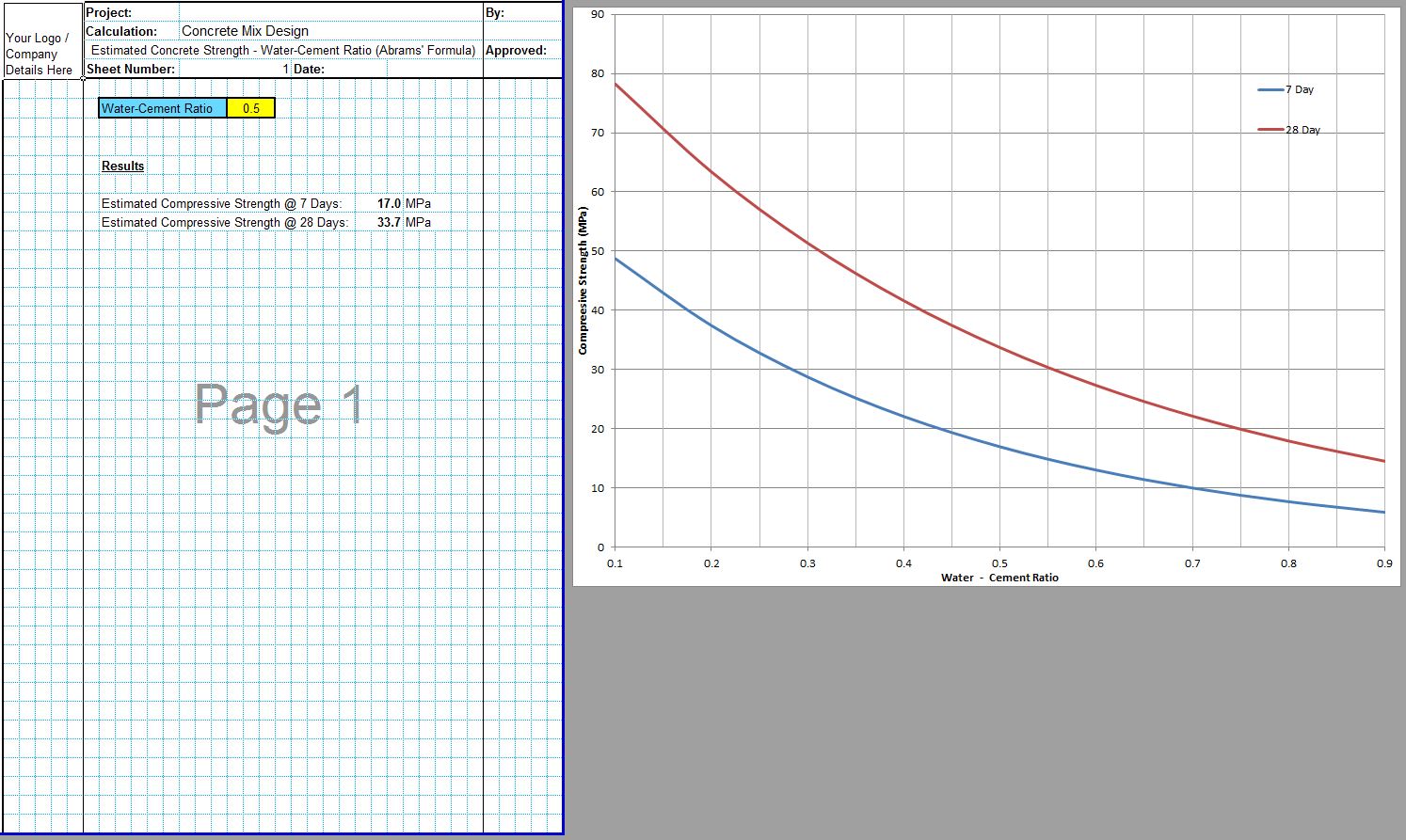

CivilWeb Grading of Aggregates in Concrete Analysis Spreadsheet

Buy now for only £5.

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.