Supplementary cementitious materials are mineral admixtures which display cementitious properties when added to concrete. Each hydrates at different speeds and affects the properties of the concrete in different ways. Supplementary cementitious materials are often referred to as pozzolanic and cementitious materials or simply as SCMs in concrete.

Supplementary cementitious materials can be used to replace ordinary Portland cement content in concrete which can decrease the costs. Many supplementary cementitious materials are also often produced from waste materials from steel, coal or other industries. Use of these waste products as supplementary cementitious materials can also improve the sustainability of the concrete, both by using less ordinary Portland cement and by using a waste product which otherwise would need to be disposed of.

Choice of Supplementary Cementitious Materials

There are a number of factors which need to be considered when specifying the cement combination for concrete. The most commonly considered properties when specifying supplementary cementing materials in concrete are detailed below.

Early Age Strength

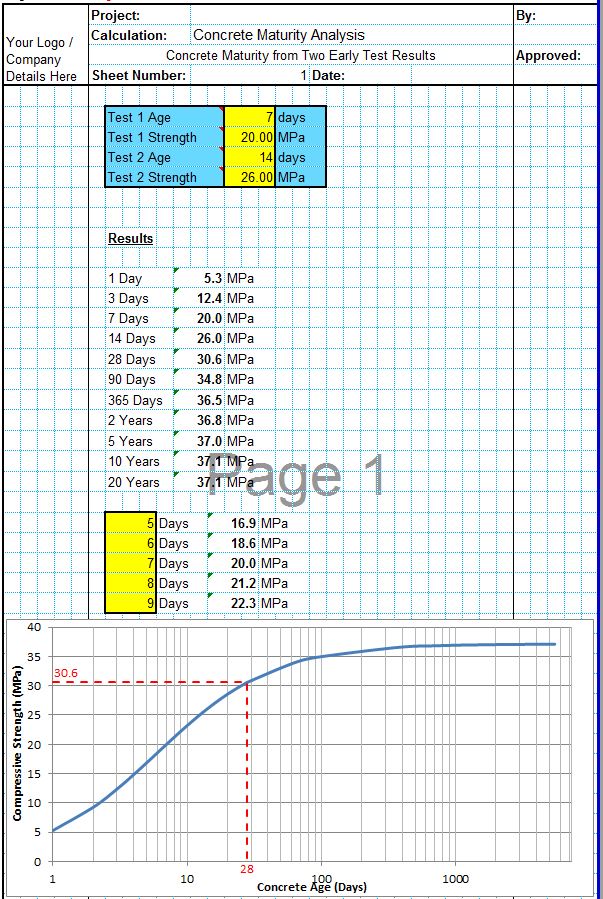

The early age strength of the concrete is important in many cases, particularly where the concrete needs to be loaded before it can reach its specified 28 day strength. Different supplementary cementitious material combinations will attain strength at different rates.

Portland Cement – These mixes have a relatively high rate of strength gain. They will typically achieve around 80% of their final strength within 7 days. For an even greater effect BS EN 197-1 includes specifications for high early strength cements, suffixed with an R for rapidly hardening. These mixes will not set much quicker than Portland cement only mixes, but will attain strength more quickly over the next few days. These mixes are however more expensive and often only allow the concrete to be put into use a few days sooner. They also release greater heat during hydration and can be more susceptible to early thermal cracking.

Portland Cement mixed with Ground Granulated Blast Furnace Slag (GGBS) – These mixes tend to gain strength more slowly, sometimes gaining only 60%-70% of their final strength after 7 days. Strength testing should be completed before the concrete is allowed to be loaded.

Portland Cement mixed with Fly Ash – These mixes also tend to gain strength more slowly than mixes using only Portland cement, often gaining only 50%-60% of their final strength after 7 days. The effects are similar to mixes containing GGBS detailed above.

Placing Temperature

The ambient temperatures, humidity and exposure conditions at the time of placing the concrete can also affect the choice of cement combination.

Portland Cement – These mixes give off a large amount of heat during hydration which makes them more resistant to cold ambient temperatures than other cement combinations. However during warmer weather this can cause the concrete to set quickly, which can make finishing the concrete more difficult and shorten the finishing window significantly.

Portland Cement mixed with GGBS – These mixes set more slowly and produce less heat of hydration than mixes using Portland cement only. This can make them susceptible to problems when placed at low ambient temperatures, with extended setting times and variable finishing times and saw cutting windows. They also tend to be less cohesive and bleed more than other mixes which can cause defects and issues with finishing. If problems are anticipated, the effects can be lessened by reducing the amount of GGBS in the mix and increasing the Portland cement content. Conversely, the above effects can be positives when placed at high ambient temperatures where the use of GGBS will extend setting times and finishing and saw cutting windows compared with Portland cement only mixes.

Portland Cement mixed with Fly Ash – These mixes also tend to set more slowly than mixes using only Portland cement leading to similar issues with cold weather as mixes containing GGBS detailed above.

Setting Time

Different cement combinations have different setting rates which affects the method and ease of finishing. Short setting times may require different methods of finishing or greater manpower, while longer setting times will impact on the construction programme and the ability to load the concrete member. This will also affect the window of time in which induced saw cuts can be completed before the concrete starts to shrink and crack.

Portland Cement – These mixes will set relatively quickly, limiting the time available for finishing. The fast setting time may also mean that saw cuts for induced joints will need to be installed less than 24 hours after the concrete is placed. This is because the fast setting time and high temperature of hydration can lead to thermal contraction cracking unless the induced joints are installed early.

Portland Cement mixed with (GGBS) – The setting time for these mixes are generally slightly slower than pure Portland cement mixes. This allows a longer time for finishing and saw cuts for induced joints can be installed later.

Portland Cement mixed with Fly Ash – These mixes tend to set even more slowly than mixes using GGBS. The effects are similar to mixes containing GGBS detailed above, but can be even more marked in cold weather.

Consistence & Workability

The consistence and workability of the fresh concrete mix is also affected by the cement combination chosen.

Portland Cement – These mixes can be more difficult to place, compact and finish than some other mixes.

Portland Cement mixed with (GGBS) – These mixes are generally more workable, easier to place, compact and finish than mixes using Portland cement only.

Portland Cement mixed with Fly Ash – The addition of fly ash into the mix will reduce the water demand of the mix by up to 6% without affecting the workability. This allows the workability to be increased without compromising the water-cement ratio or the strength. This can also be used to mitigate other workability factors such as angular aggregates used to increase strength or where the aggregates are expected to be poorly graded. The cohesiveness of the concrete is also improved with reduced bleeding compared to Portland cement only mixes. These effects are due to the spherical shape of the fly ash particles which reduces the amount of water required to coat the particles with cement paste. The lower density of the fly ash particles also serves to increase the cement paste volume.

Abrasive Resistance

Cement combinations with additions have been shown to achieve significantly reduced resistance to abrasive if they are air cured only. For this reason it is important that concrete pavements constructed using cement combinations including supplementary cementitious materials are cured properly in accordance with the supplier’s instructions. If they are cured correctly the concrete will attain a similar abrasive resistance to cement only mixes.

Conclusions

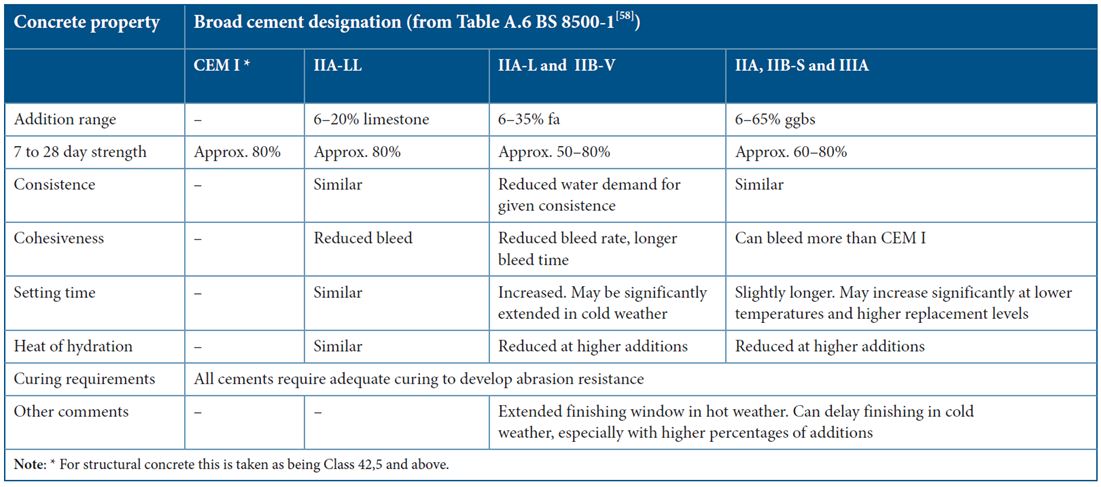

The above parameters and general effects on the properties of concrete are quite neatly summarized in the below tables;