The water absorption of aggregate used for concrete has a significant effect on the required water content of the mix in order to produce concrete which is sufficiently workable in its fresh state and sufficiently strong in its hardened state. The water absorption of aggregates goes hand in hand with the moisture content of the aggregate to determine water demand.

Water Absorption of Aggregate

All normal weight aggregates include pores which can be filled with water. When these pores are full the aggregates can also maintain a thin film of water around the aggregate particles. The water absorption of the aggregates along with the moisture content of the aggregates are important factors to consider when proportioning the concrete mix, particularly the amount of water required.

The water absorption of the fine aggregate and the water absorption of the coarse aggregates may differ significantly, particularly when they are not coming from the same source or have not been stored in the same conditions.

The water absorption value for aggregates describes the percentage increase in weight between the dry aggregate and the saturated aggregate. Therefore the absorption value is the amount of water which the aggregates are able to hold.

The absorption value can be ascertained using the water absorption test described in BS EN 1097-6 and should generally be less than 2% in order to prevent large variations of water in the concrete mix during production. It can be difficult to control the moisture content of high absorption aggregates in practice, leading to variations in the quality of the produced concrete.

Moisture Content of Aggregate

The moisture content of the aggregates determines whether the aggregate will effectively add water to the concrete mix or whether the aggregates will take water away from the mix. If the aggregates are over saturated this means that the moisture content of the fine aggregates and coarse aggregates exceeds the water absorption of the fine aggregates and coarse aggregates. Effectively the aggregates contain a higher moisture content than they can absorb, meaning that they will effectively add water to the mix. Conversely if the aggregates contain a lower moisture content than the water absorption, then the fine and coarse aggregates will take water from the mix in line with their absorption value.

Effects of Water Absorption of Aggregate

As stated above aggregates with a high water absorption value (greater than around 2%) can create problems controlling the moisture content of the aggregates in practice. This leads to variability in aggregate moisture content which can make it difficult for the correct water content of the concrete mix to be determined.

Aggregates with a high absorption value are likely to increase shrinkage during drying. High water absorption aggregates used for concrete pavements are also more susceptible to popouts and are less resistant to freeze-thaw cycles.

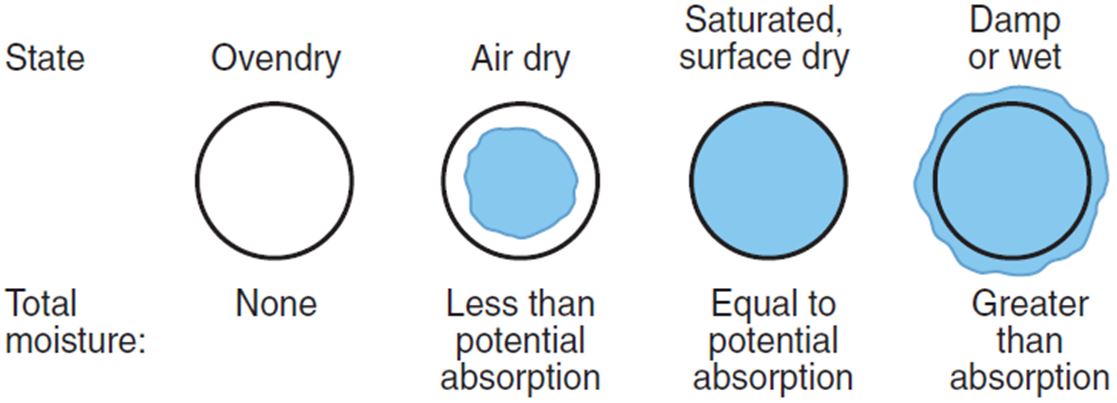

The moisture content of aggregates can be measured using the moisture content of aggregate test detailed in BS EN 1097-5. The different states of moisture content in aggregates is illustrated below.

The amount of water to be added when producing the concrete mix depends on whether the aggregates contain excess free water (damp or wet state) or whether they are air dry and contain less water than their absorption value.

Controlling the Moisture Content of Aggregate

Aggregate stockpiles should include methods of draining excess water and the moisture content of aggregates should be monitored regularly and measured prior to inclusion in the concrete mix so the water content can be adjusted if necessary. This is particularly the case where the aggregates have a high water absorption value or where the aggregates are stored in an exposed location. Variations in aggregate moisture content of only a few tenths of a percent will have a measurable effect. The aggregates should be tested using the moisture content of aggregate test before production of the concrete commences and then again several times during the shift. The aggregates should also be tested following changes in weather conditions such as during rain.

Bulking Effects due to Moisture Content of Aggregates

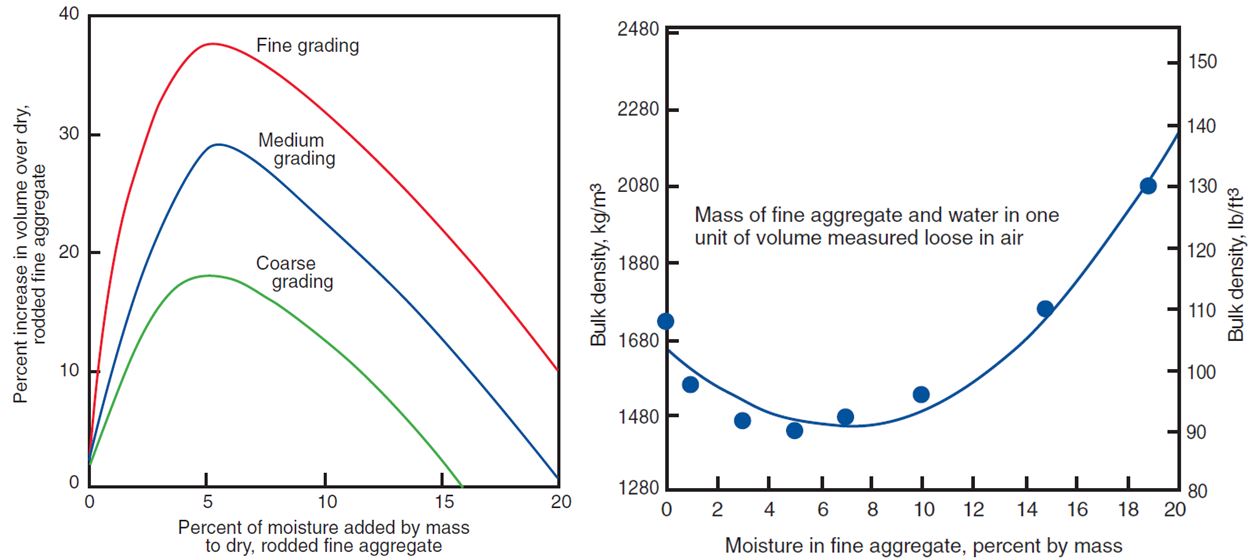

Another factor to consider when proportioning water and aggregates in a concrete mix is the bulking effect. Bulking is the increase in volume of aggregates depending on the moisture content of the fine aggregates. Moist fine aggregates will increase in volume compared with dry fine aggregates. The bulking effect occurs because the surface tension of the moisture content effectively separates the aggregate particles, creating an increase in volume. Bulking can occur whenever moist fine aggregates are handled, even when the aggregates were previously fully consolidated.

Bulking effects need to be considered when measuring aggregates prior to concrete mix production. As the volume can vary depending on the bulking effect, aggregates are usually portioned by weight adjusting for moisture content rather than based on volume. Care must be taken to ensure that the mix of aggregates is proportioned correctly.

The below graphs illustrate the bulking effect, showing the increase in volume and the changes in density.

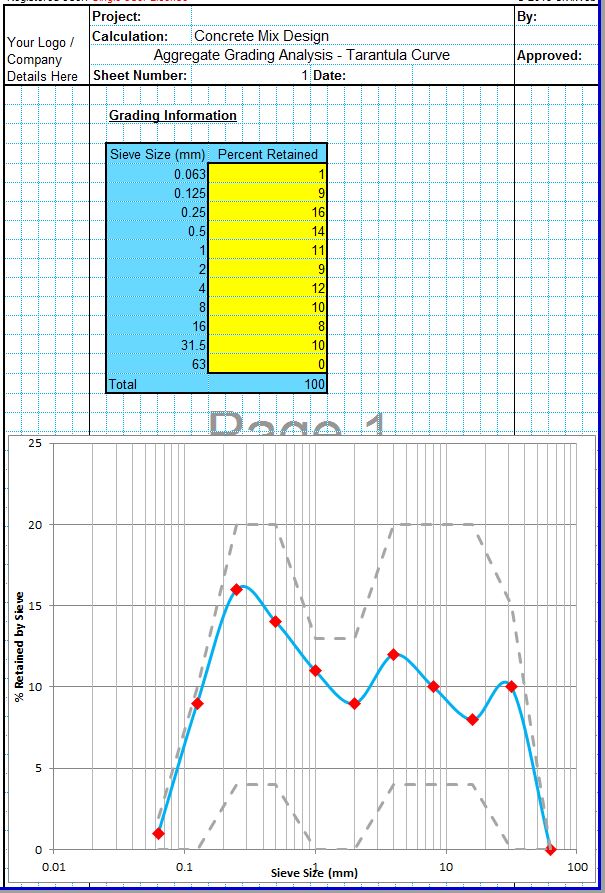

CivilWeb Grading of Aggregates in Concrete Analysis Spreadsheet

Buy now for only £5.

Our full Concrete Properties Suite of spreadsheets is available for only £10.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.