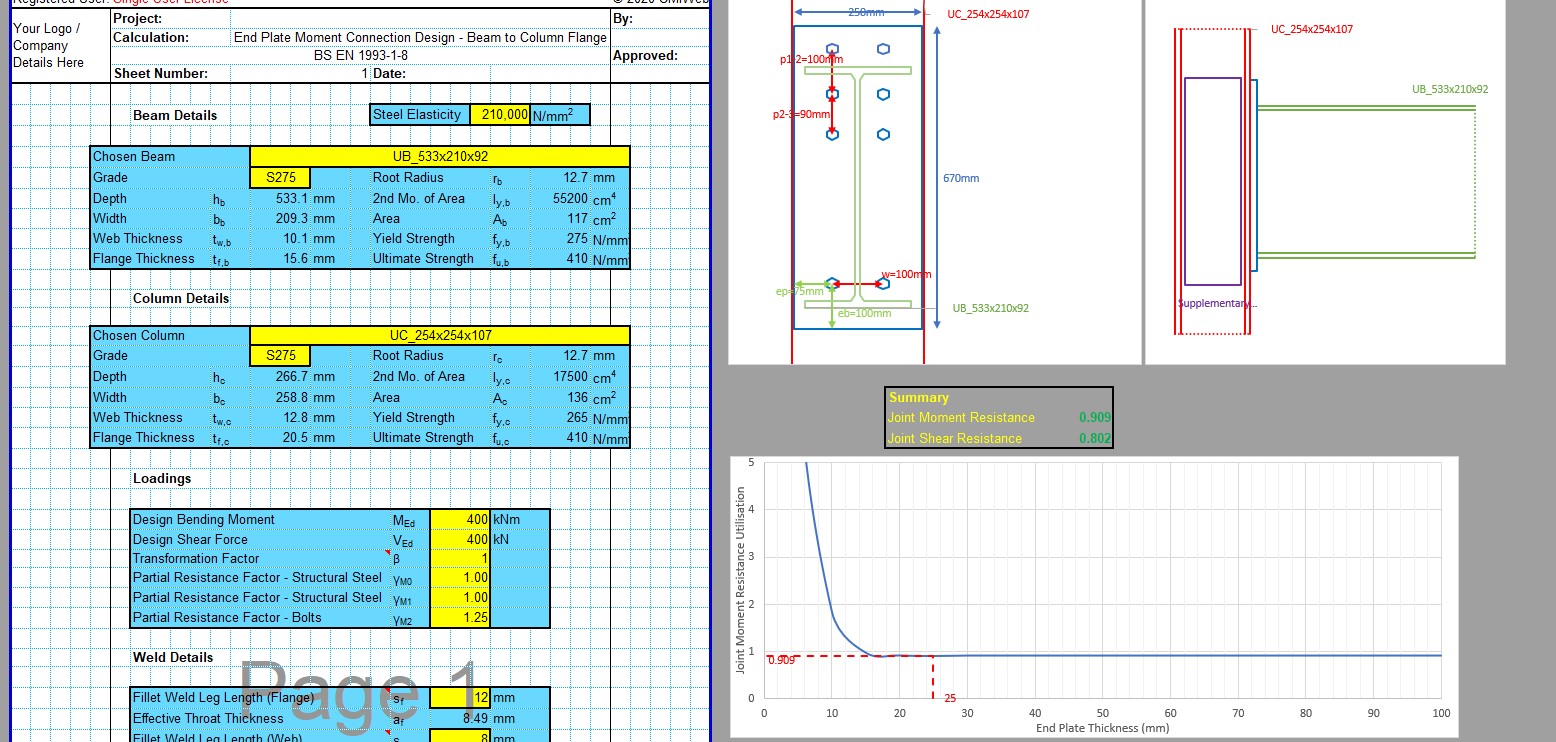

The CivilWeb End Plate Connection Design Excel Spreadsheet is an advanced structural steel design spreadsheet which can be used to design end plate connections in accordance with BS EN 1993-1-8. The spreadsheet includes a total of 9 separate design sheets covering the design of full and partial end plate connections to column webs or flanges, and also the design of extended end plate moment connections. Each spreadsheet includes unique design and analysis tools which show the user exactly where the end plate connection can be optimised, saving hours of iterative design work. The CivilWeb End Plate Connection Design Excel Spreadsheet can be purchased for only £19.99.

Alternatively the CivilWeb Steel Connection Design Spreadsheet Suite includes end plate connections along with fin plates, splices, welds and base plate design spreadsheets. This powerful suite of spreadsheets can be used to design any commonly used steel connections and is available to purchase at the bottom of this page for only £29.99.

Or why not buy our best value bundle? Our Full Steel Design Spreadsheet Suite can be purchased at the bottom of this page for only £49.99. This suite includes all of our steel design spreadsheets and represents an incredible saving of 66%. This suite can also be purchased at the bottom of this page.

End Plate Connection Design Excel

End plate connections are simple flexible connections typically between a steel beam and steel column. The end plate connection consists of a single plate of steel which is welded onto the end of the steel beam. This end plate can be full depth (encompassing the full height of the steel beam) or partial depth (where the end plate is shorter than the depth of the beam). See above for examples of a full depth end plate and a partial depth end plate.

The end plate is then bolted to the column web or flange onsite. End plate connections are commonly used because they are typically low cost and can provide a robust connection. However they are difficult to adjust onsite and must be fabricated to relatively low tolerances in order to match up with the column. There is usually little space for error which can lead to delays if a steel section must be sent back for refabrication. In some cases packers can be used to compensate for fabrication tolerances though this is not always possible. The beams must be cut to length with greater precision in order to ensure that the beam is the correct length when the end plate is fitted.

End plates can be used effectively with skewed beams and can be fabricated to tolerate minor offsets in beam and column joints. End plate connections are not typically used on taller steel structures.

In many cases it is simpler and easier to specify standard end plate connections across a steel frame rather than design and specify each individual connection independently. This removes some of the sources of common errors such as misreading drawings and erecting beams in the wrong place or sequence. This requires the designer to take care when designing the steel beams and columns also in order to make standard joints possible across the whole steel frame.

Simple End Plate Connection Design Excel

The CivilWeb End Plate Connection Design Excel Spreadsheet includes four separate sheets for the design of all commonly used simple end plate connections. This includes the following;

- Partial depth end plate connection design to column web

- Partial depth end plate connection design to column flange

- Full depth end plate connection design to column web

- Full depth end plate connection design to column flange

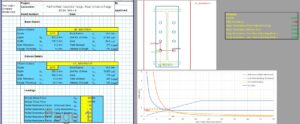

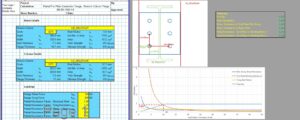

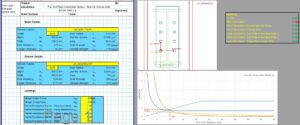

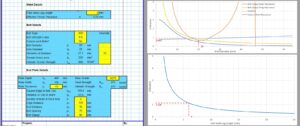

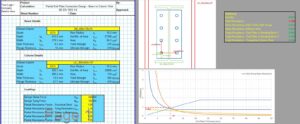

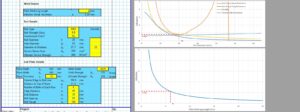

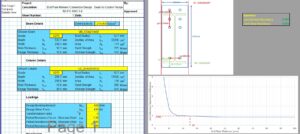

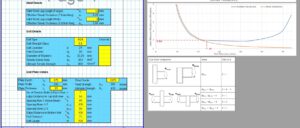

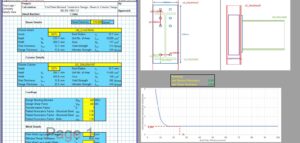

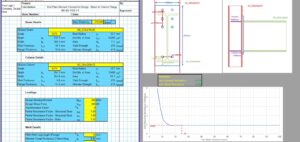

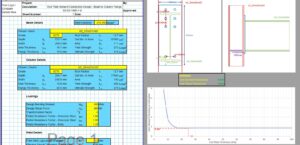

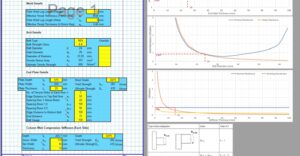

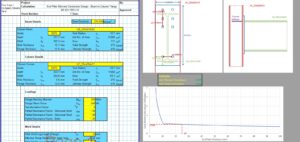

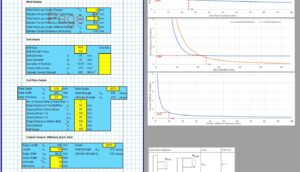

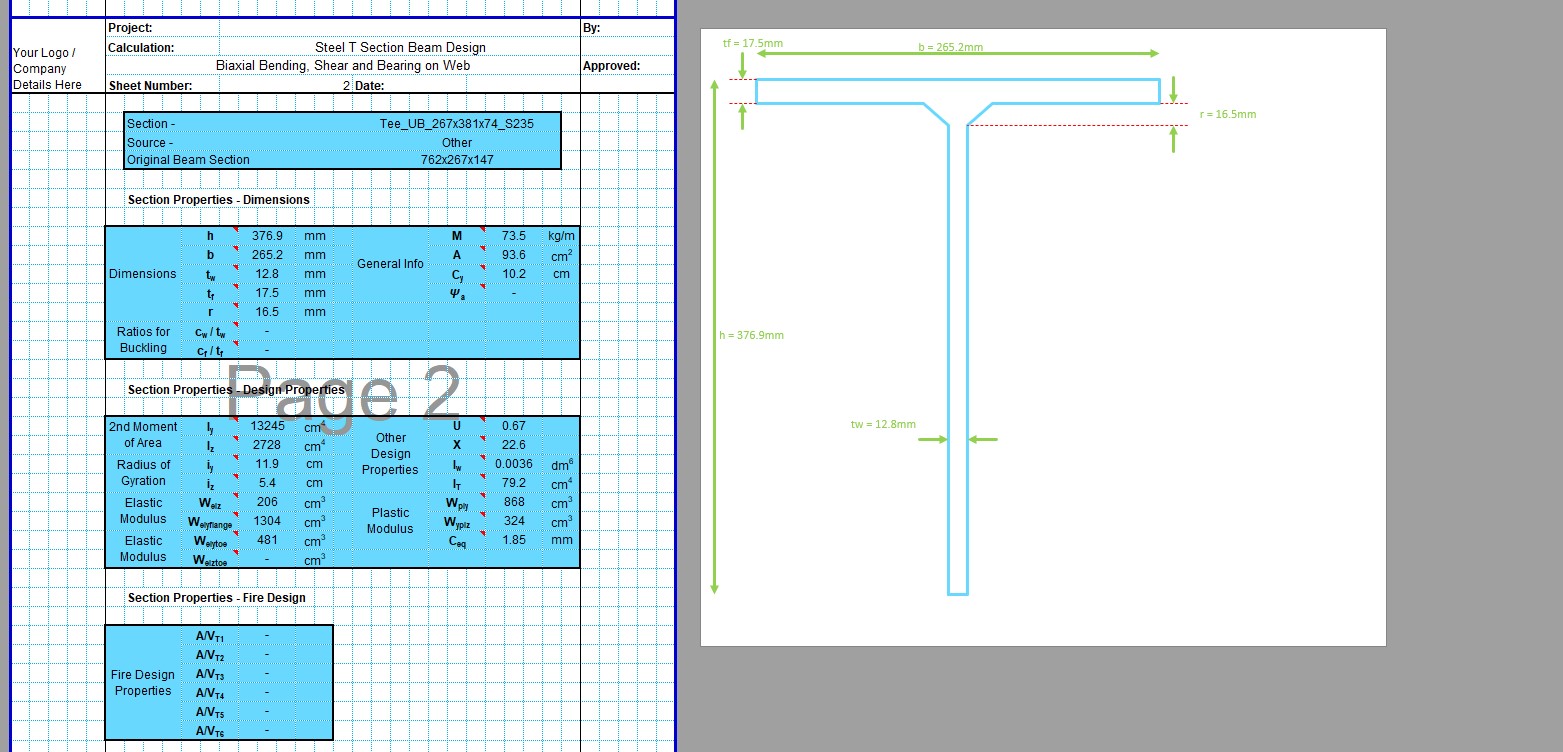

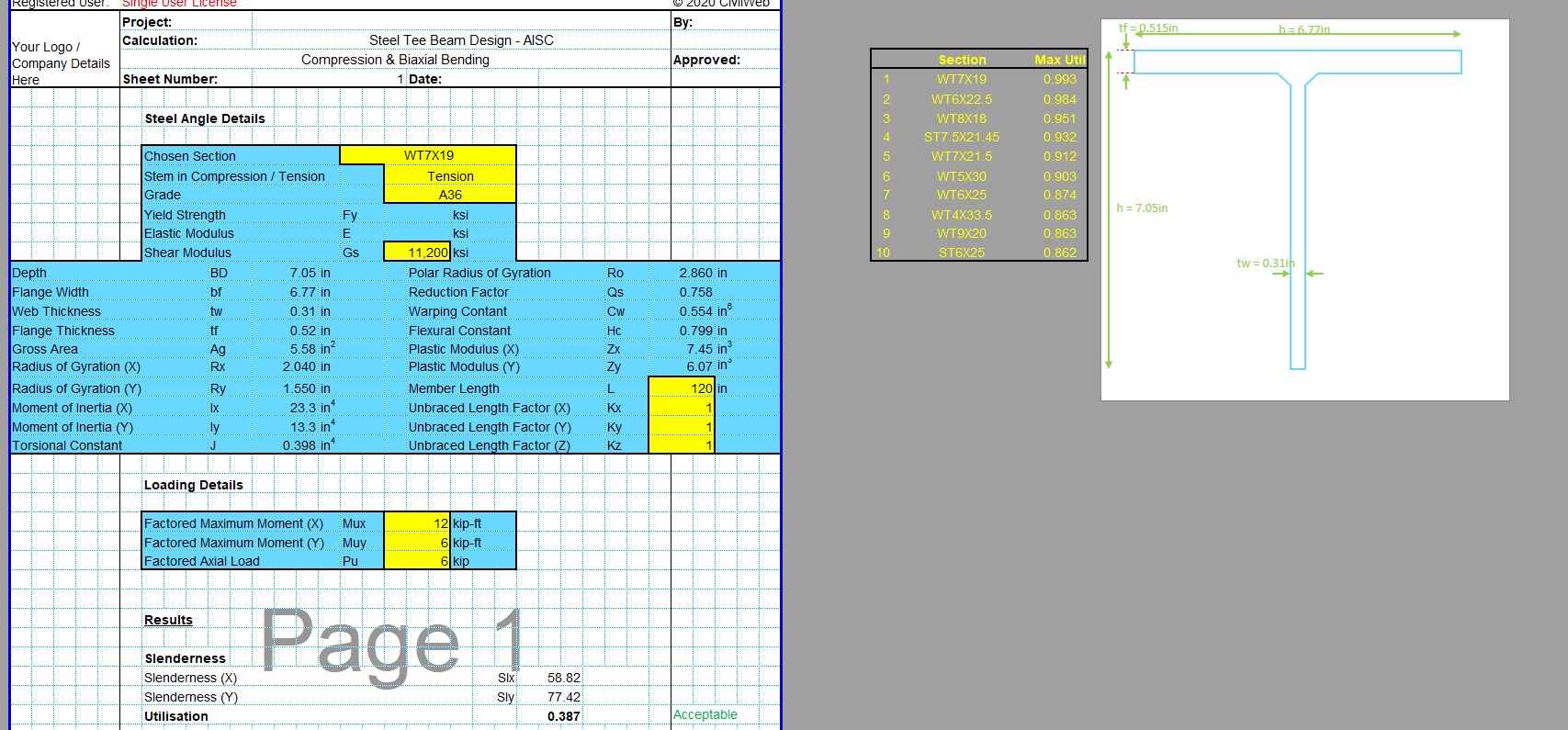

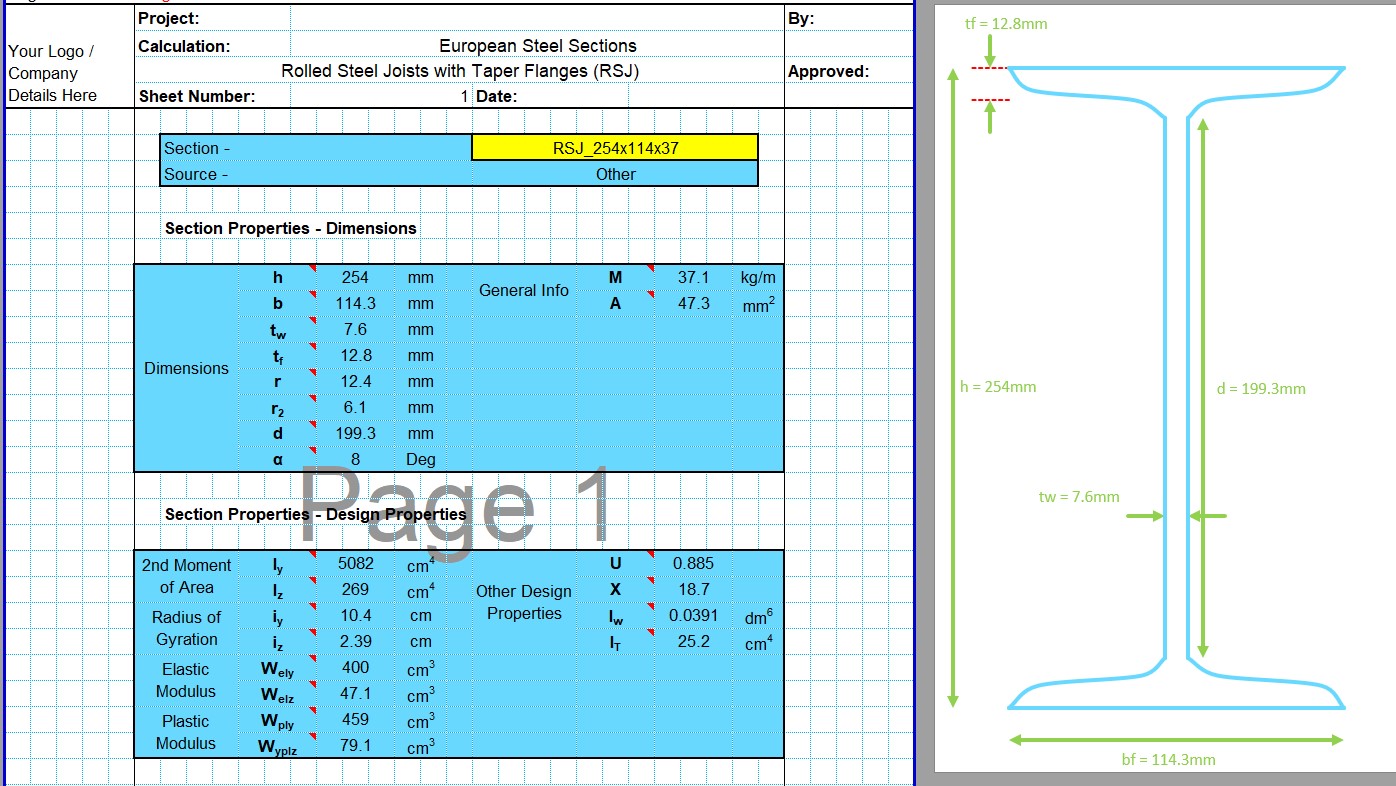

First the user must enter the geometrical and loading details for the end plate connection. The user can choose from any standard I shaped beam or column section including UB, UC, UBP, HE, IPE, HD, HLZ, HL and HP sections. In total geometrical and design details for over 500 different sections are included in the spreadsheet.

Next the user inputs the loadings to be resisted by the connection and the partial action factors which are pre-set in accordance with BS EN 1993-1-8 though these can be altered to suit alternative standards.

Then the user can input the fillet weld details, bolt sizes and end plate dimensions. The CivilWeb End Plate Connection Design Excel Spreadsheet allows the user to choose from any standard bolt type from M1.6 to M64. In total 29 different standard bolt sizes can be selected. The spreadsheet automatically chooses geometrical information for standard bolts, though these can be overridden by the designer where required to suit any bolt.

The end plate design spreadsheet updates a dynamic drawing of the end plate, beam, column and bolts to show the user exactly what end plate connection is being analysed. This unique feature removes the risk of the user accidentally entering inputs incorrectly and shows key dimensions which can be used for specification and fabrication.

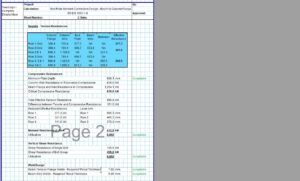

The end plate design spreadsheet then automatically completes all the critical calculations required for the evaluation of the end plate connection in accordance with BS EN 1993-1-8. All critical calculations are shown with a utilisation factor, showing exactly how much of the end plate connections capacity is being used on each case. This allows the user to see exactly where the end plate connection is most stressed and where any alterations to the connection can be made.

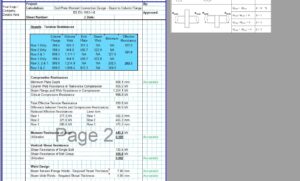

The calculations undertaken automatically by the spreadsheet include;

- Ductility – to ensure the joint is sufficiently ductile

- Weld Resistance

- Shear Resistance of the Bolt Group

- Shear Resistance of the Beam Web

- End Plate Bending Resistance for Tying Forces

The results of these calculations are shown in green or red depending on whether the end plate connection resistance is sufficient or not, showing the user instantly where any issues may lie. The spreadsheet also returns a summary of the calculations at the top of the end plate design spreadsheet which can be seen at a glance while the designer is adjusting any of the components.

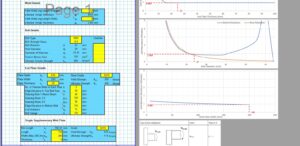

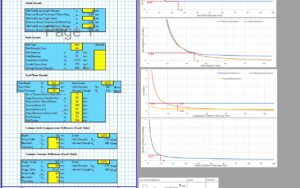

The CivilWeb End Plate Connection Design Excel Spreadsheet also includes unique design and analysis graphs which plot the resistance utilisations of the connection against alterations to the end plate thickness, bolt diameter or weld leg length. This shows the user at a glance exactly how to adjust these main design parameters in order to optimise the design. This saves the designer hours of iterative design work which would otherwise be required in order to ensure that the design is optimised.

Extended End Plate Moment Connection Spreadsheet

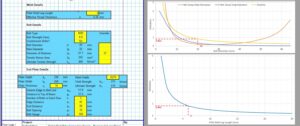

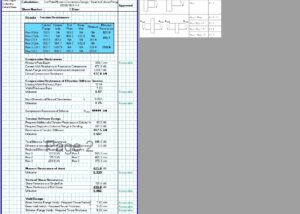

In addition to simple end plate moment connections, the spreadsheet also includes 5 separate spreadsheets for the design of extended end plate moment connections. This includes separate sheets for the design of moment connections where web compression stiffeners, tension stiffeners and supplementary web plates are required.

These sheets include all the same features as described above, but suited to extended end plate moment design.

CivilWeb End Plate Connection Design Excel Spreadsheet

The CivilWeb End Plate Connection Design Excel Spreadsheet is an advanced steel connection design spreadsheet which calculates the capacity of any end plate connection in minutes, fully in accordance with BS EN 1993-1-8. However, the unique design and analysis tools make the spreadsheet easy to use, and allow a fully optimised, fully compliant end plate connection design to be completed in minutes, saving hours of design work on every connection design.

Buy the CivilWeb End Plate Connection Design Excel Spreadsheet now for only £19.99.

Or why not buy our best value bundle, the full CivilWeb Steel Design Suite which includes all of our steel design spreadsheets for only £49.99, a saving of 66%.

Download Free Trial Version

To try out the free trial version of this software, please enter your email address below to sign up to our newsletter and we will send your free version now.