The CivilWeb Tube Moment of Inertia Calculator is a powerful collection of spreadsheets which can be used to determine all the design section property information for Circular hollow sections (CHS), Tubes and Pipe shaped sections. The spreadsheet includes all the latest information on circular hollow sections published in national standards including US (AISC), European, UK and Indian steel sections. The spreadsheet also includes a comprehensive collection of section property calculators which can be used to determine all the required design information on non-standard or bespoke circular hollow sections, elliptical hollow sections (EHS) and hollow semi-circular and sector sections of any dimensions.

This combination of comprehensive standard section information and non-standard section calculators allows the designer to determine all the design information required on circular hollow sections of any size, standard or non-standard. The CivilWeb Tube Moment of Inertia Calculator can be purchased on this page for only £9.99.

Alternatively the full Steel Section Properties Excel Suite includes all the design section information from all standard section shapes and sizes, totalling thousands of different sections. It also includes all our non-standard sized beam section property calculators. Together this powerful suite of spreadsheets includes all the information required for the design of any standard or non-standard steelwork section. This unique collection of design information and calculators is available for only £29.99.

Or why not buy our best value bundle? Our Full Steel Design Spreadsheet Suite can be purchased at the bottom of this page for only £49.99. This suite includes all of our steel design spreadsheets and represents an incredible saving of 66%. This suite can also be purchased at the bottom of this page.

Circular Hollow Section Uses

Circular hollow sections are a very useful shape which is used commonly in steel frame construction, piling and other construction types. Circular hollow sections are also very commonly used in aluminium and other metals as well as steel.

Circular hollow sections are very useful. The hollow shape means that the section is much more efficient at resisting bending than the equivalent solid circular sections. This is because the material in the centre of the section is much less resistant to bending than the material at the outside of the section. This is because of the lever arm effect which multiplies the bending resistance of the material by its distance from the neutral axis. A larger diameter circular hollow section is much more resistant to bending than a smaller diameter solid circular section of the same mass, at a similar cost.

Circular hollow sections show more resistance to torsion than equivalent open sections which might be used for the same purpose. In cases where torsion is a significant effect circular or other hollow sections are often specified.

The main advantage with circular hollow sections compared to other shapes is the circular hollow sections equal resistance to bending in any direction. Open sections such as I shaped and C shaped sections are very good at resisting bending in one direction, but not so good at resisting bending in the other direction. Rectangular or square hollow sections are good at resisting bending in both main directions, however are not so good at resisting bending moments acting in different angles. The circular hollow sections perfect symmetry at every angle makes the shape uniquely resistant to bending in any direction. This is very useful for columns and other members where wind loads for example can equally act on the member in any direction. For this reason circular hollow sections are very commonly used as columns and piles.

This symmetrical layout can be a disadvantage however when the member is likely to experience large bending moments in one direction only. In these cases the circular hollow section includes a lot of material which is ineffectively placed closer to the neutral axis. For this reason circular hollow sections are rarely used as main members when bending is predominantly in one direction. I shaped beams are optimised to suit bending in one direction, square or rectangular hollow sections are well suited to bending in two directions, circular hollow sections are best suited to bending in any direction.

Another disadvantage with the circular hollow section shape is that the section is closed. This means that there is no easy access inside the section for the installation of bolts and other fixings. Open sections such as I shape beams, C shape channels or L shape members are easy to install bolts through, even after installation. Closed sections such as the circular hollow section are much more difficult or even impossible to install some types of fixings which limits their use in some circumstances. For this reason circular hollow sections are often used alongside open sections in steel frame constructions.

CivilWeb Tube Moment of Inertia Calculator - Section Properties Included

The CivilWeb Tube Moment of Inertia Calculator includes all the latest published information on standard sized circular hollow sections from US (AISC), UK, European and Indian steel standards. The spreadsheet also includes information on historical circular hollow sections from old UK and US steel standards from the last 100 years.

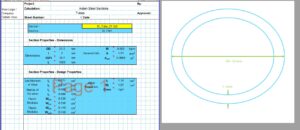

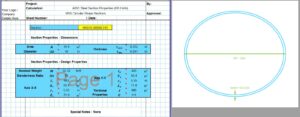

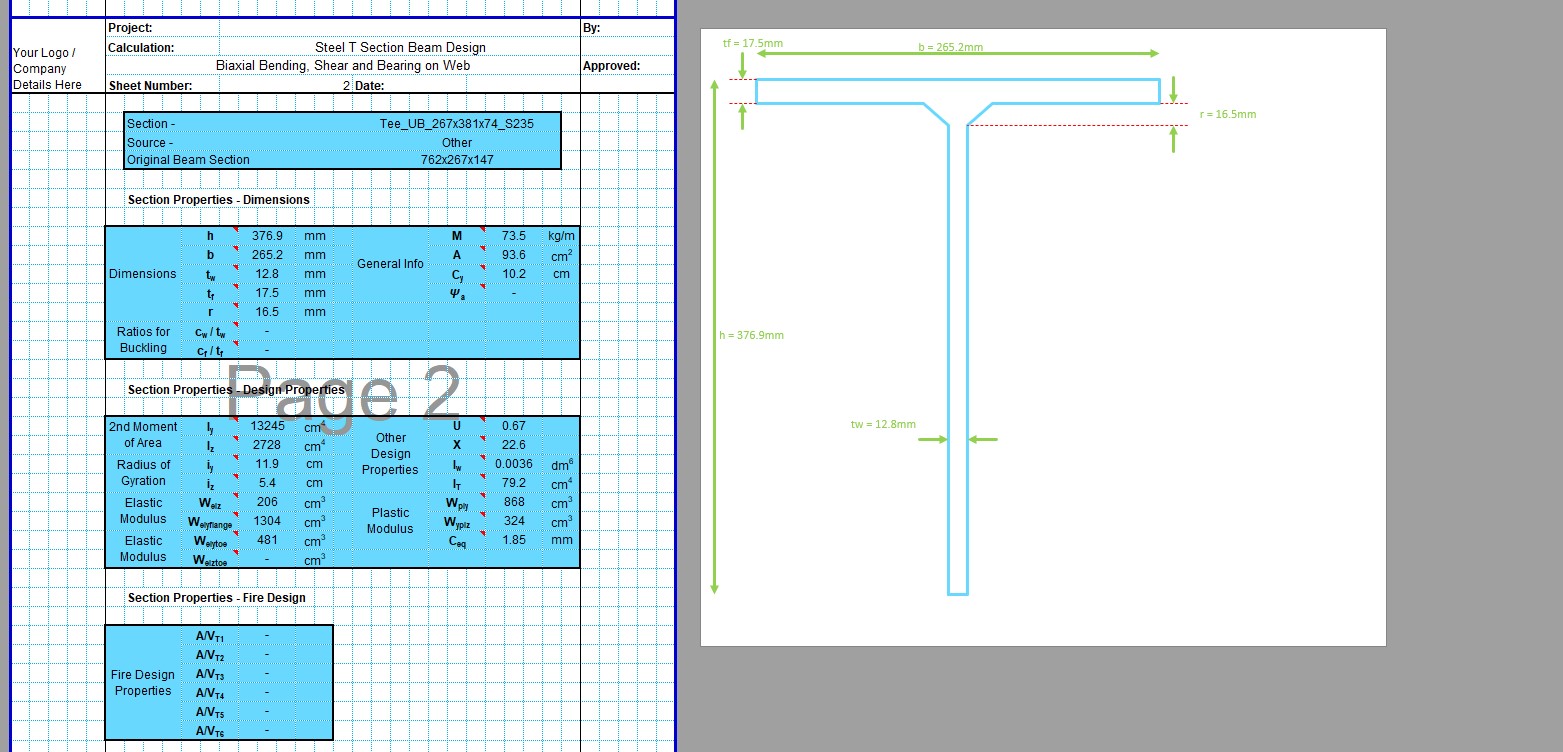

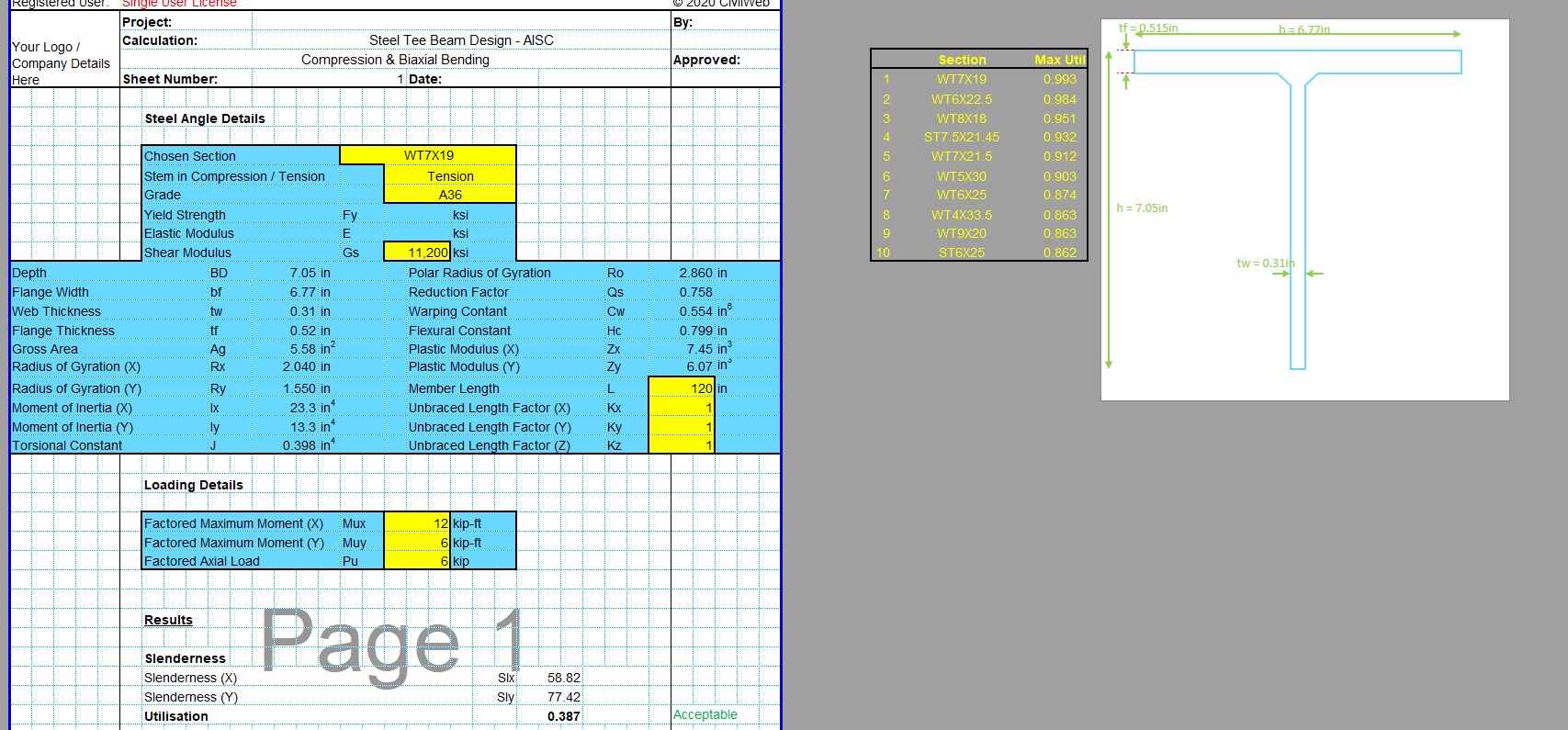

The spreadsheet includes the following published design section properties for hot formed and cold formed circular hollow sections as well as elliptical hollow sections;

- Section Diameter and Thickness

- Mass per Metre and Length per Tonne

- Surface Area per Metre and per Tonne

- Second Moment of Area (Pipe Moment of Inertia Calculator)

- Radius of Gyration

- Elastic and Plastic Section Moduli

- Torsional Constant of Inertia

- Torsional Constant Modulus

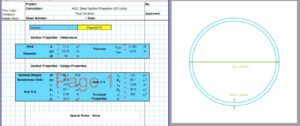

In addition to the published information about standard sized circular hollow sections, the CivilWeb Tube Moment of Inertia Calculator also includes a section property calculator which is able to calculate all the section information required for the design of non-standard sized circular hollow sections of any dimensions. The designer can specify any diameter and thickness and the spreadsheet will calculate all the properties required for the design of this section. This can also be used for the analysis of existing structures with non-standard sized sections.

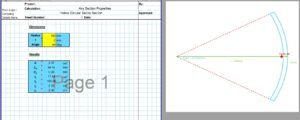

The CivilWeb Moment of Inertia Calculator Tube includes the following calculators for user specified tubular sections. The spreadsheet can also be used to calculate the same section information for user specified Elliptical Hollow Sections (EHS), Hollow Semi-Circular Sections and Hollow Circular Sector Sections.

- Sectional Area

- Centre of Gravity Location

- Pipe Moment of Inertia Calculator (Second Moment of Area)

- Radius of Gyration

- Elastic Section Modulus

- Plastic Section Modulus

- Torsional Constant of Inertia

CivilWeb Tube Moment of Inertia Calculator

The CivilWeb Tube Moment of Inertia Calculator is a vital tool for the design of circular hollow sections of any material, particularly steel. The spreadsheet includes all standard circular hollow section data from the UK, US (AISC), European and Indian national steel standards. The spreadsheet also includes a powerful section property calculator tool which can calculate the section properties for any sized circular hollow section. Together these tools allow the designer to determine all the section property information required for the design of circular hollow sections for any material or any size.

Buy the CivilWeb Tube Moment of Inertia Calculator now for only £9.99.

Or why not buy our best value bundle, the full CivilWeb Steel Design Suite which includes all of our steel design spreadsheets for only £49.99, a saving of 66%.

Download Free Trial Version

To try out the free trial version of this software, please enter your email address below to sign up to our newsletter and we will send your free version now.