The Colebrook White Roughness Coefficient or equivalent sand roughness coefficient is a coefficient describing the internal roughness of the drainage pipe. It is used in the Colebrook White Equation. While this coefficient may have the units of length it cannot be measured directly from the pipe. The value of the coefficient must be determined from hydraulic tests. While hydraulic tests can confirm the roughness coefficient of the pipe in laboratory conditions, in practice the roughness of the pipe is dictated by other factors as described below. For this reason manufacturer’s roughness coefficients should not be used for general drainage design.

Design Values

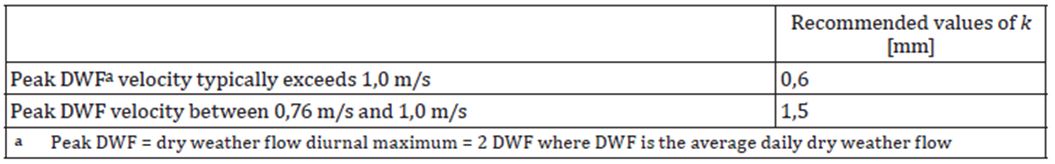

While the true roughness coefficient can be affected by a number of conditions including pipe material, condition and sedimentation conditions, for general design purposes it is recommended that roughness coefficient values of 0.6mm and 1.5mm are used for general surface water and foul water drainage pipes respectively. These values have typically been used for design in the past and therefore these values are covered in the published charts and tables. This is also the recommendation in Sewers for Adoption for design of new drainage systems. BS EN 16933-2 recommendations for foul and combined sewers is shown in the below table;

BS EN 16933-2 also recommends that these roughness values include some allowance for local headlosses such as those from junctions and pipe joints.

While values of 0.6mm and 1.5mm are used as standard, in some cases a variation from these values may be justified. This can be the case where the capacity of a newly installed pipe is being calculated or where analysis is being done on an old sewer with significant sliming or defects.

Design Considerations

The following factors should be taken into account when determining a suitable roughness coefficient value;

- Pipe Material – this is generally only a concern for analyzing new pipes or pipes which are not expected to be subjected to any degree of sedimentation throughout the design life. The appropriate roughness coefficient value for new pipes can be taken from the manufacturer. Alternatively typical values for common pipe materials are included at the bottom of this page.

- Pipe Condition and Age – The age and general condition of the pipe should be taken into account as a drainage pipe will naturally deteriorate towards the end of its design life which will increase the effective roughness coefficient. Typical values including for general age and condition are included at the bottom of this page.

- Pipe Alignment – The alignment of the pipe will affect the roughness coefficient. Any curves or misalignment of the pipe will increase the effective roughness coefficient and should be allowed for.

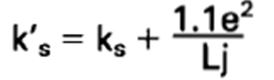

- Pipe Joints – The condition, quality and type of pipe joints can affect the effective roughness coefficient. Poorly designed or installed joints will increase the roughness coefficient and should be allowed for where appropriate. Where eccentricities are measured in pipe joints, this can be allowed for in the roughness coefficient using the following equation;

k’s = Amended roughness coefficient (mm)

e = Joint Eccentricity (mm)

Lj = Pipe Length Between Joints

This is typically used for clayware joints with eccentricities in excess of 8mm. A calculator for this equation is included in the CivilWeb Pipe Flow Calculator spreadsheet package.

- Slimes, Biofilms and Growths – Some sliming or biological growth is expected in particularly in foul water drainage pipes though surface water pipes can also be affected. The extent of this growth will depend on the type of runoff or foul water handled and the velocity of the water. The presence of this slime in foul sewers will usually override the effects of any other factors such as joint types and pipe materials. This slime tends to form on any pipe material in a similar way.

- Sedimentation – The sedimentation conditions in the pipe should be evaluated as this can affect the roughness coefficient. This depends largely on the sediments expected in the runoff or foul water and the velocities. Further guidance and a procedure for calculating an adjusted roughness coefficient including for the effects of a sediment bed are included here. The CivilWeb Pipe Flow Calculator spreadsheet package includes a tool for completing these calculations.

The Highways Agency has issued some simplified guidance on the equivalent roughness coefficients of drainage pipes with sedimentation. This took the form of two tables showing adjusted roughness coefficients for good condition pipes (initial roughness 0.6mm) and deteriorated pipes (initial roughness 2.1mm). These tables are reproduced in the user guide provided with the CivilWeb Pipe Flow Calculator spreadsheet.

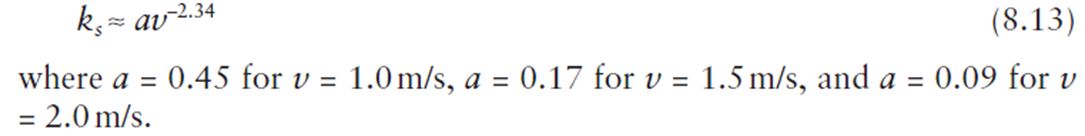

For rising mains the sliming tends to more uniform and more closely adhered to the pipe surface. For this reason Sewers for Adoption allows for roughness coefficient values of 0.3mm for mean velocities up to 1.1m/s, 0.15 for mean velocities up to 1.8m/s. Alternatively the following equation can be used for rising mains;

A calculator for this equation for rising mains is included in the CivilWeb Pipe Flow Calculator spreadsheet package.

Comparison with Manning’s Coefficient

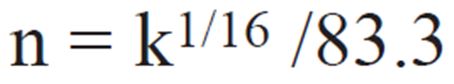

There is an empirical equation which can be used to approximately convert roughness coefficient values to Manning roughness values, shown below.

A calculator for this equation for converting roughness values is included in the CivilWeb Pipe Flow Calculator spreadsheet package.

Typical Material Roughness Coefficients (ks) for Colebrook-White Equation

| Surface Water (New) | Suggested Design Value | Likely Range | |

| Asbestos Cement | 0.03 | 0.015 | 0.03 |

| Concrete | |||

| Precast concrete pipes With 'O' ring joints | 0.15 | 0.06 | 0.6 |

| Precast concrete pipes Without Ring Joints | 0.3 | 0.06 | 1.5 |

| Fibre Reinforced Concrete | 0.03 | 0.015 | 0.03 |

| Prestressed | 0.06 | 0.03 | 0.15 |

| Monolithic With Steel Forms | 0.6 | 0.3 | 1.5 |

| Monolithic With Rough Forms | 1.5 | 0.6 | 1.5 |

| Clayware | |||

| With Sleeve Joints and 'O' Ring Seals | 0.06 | 0.03 | 0.15 |

| With Spigot and Socket Joints | 0.15 | 0.03 | 0.3 |

| Brass/Copper | 0.003 | ||

| Glass | 0.003 | ||

| Aluminium | 0.003 | ||

| Lead | 0.003 | ||

| Pitch Fibre | 0.03 | ||

| Glass Fibre | 0.06 | ||

| Iron | |||

| Wrought Iron | 0.06 | 0.03 | 0.15 |

| Rusty Wrought Iron | 0.6 | 0.15 | 3 |

| Galvanised Iron | 0.15 | 0.06 | 0.3 |

| Cast Iron | 0.3 | 0.15 | 0.6 |

| Bitumen or Spun Concrete Lined Ductile Iron | 0.03 | ||

| Steel | |||

| Uncoated | 0.03 | 0.015 | 0.06 |

| Coated | 0.06 | 0.03 | 0.15 |

| Rusty | 0.15 | 0.15 | 0.3 |

| Rivetted | 3 | 0.3 | 6 |

| Wood Staved | 0.6 | 0.3 | 1.5 |

| UPVC | |||

| Twin Walled with Coupling Joint | 0.006 | 0.003 | 0.006 |

| With chemically cemented joints | 0.03 | 0.015 | 0.06 |

| With spigot and socket joints, 'O' ring seals at 6 m to 9 m intervals | 0.06 | 0.03 | 0.15 |

| Brickwork | |||

| Glazed | 1.5 | 0.3 | 1.5 |

| Well pointed | 3.0 | 0.6 | 3.0 |

| Old brickwork | 15.0 | 3.0 | 15.0 |

| Concrete Channels | |||

| Trowel Finish | 1.5 | 0.5 | 3.3 |

| Float Finish | 3.3 | 1.5 | 5.0 |

| Gravel Bed | 7.0 | 3.3 | 18.0 |

| Unfinished | 7.0 | 2.0 | 18.0 |

| Sprayed Concrete Finish, Good Section | 14.0 | 5.0 | 43.0 |

| Sprayed Concrete Finish, Wavy Section | 33.0 | 10.0 | 70.0 |

| Unlined Rock Channels | |||

| Homogeneous Rocks, Granite | 150 | 60 | 300 |

| Diagonally Bedded Slates | 300 | 300 | 600 |

| Earth Channels | |||

| Straight Uniform Artificial Channels | 60 | 15 | 150 |

| Straight Natural Channels Free from Shoals, Boulders, Weeds | 300 | 150 | 600 |

| Combined Sewers (velocities between 0.5m/s and 1.0m/s) | Good | Normal | Poor |

| Concrete | 0.6 | 1.5 | 3.0 |

| Asbestos Cement | 0.6 | 1.5 | 3.0 |

| Clayware | 0.6 | 1.5 | 3.0 |

| UPVC | 0.3 | 0.6 | 1.5 |

| Combined Sewers (velocities above 1.0m/s) | Good | Normal | Poor |

| Concrete | 0.3 | 0.6 | 1.5 |

| Asbestos Cement | 0.3 | 0.6 | 1.5 |

| Clayware | 0.15 | 0.3 | 0.6 |

| UPVC | 0.1 | 0.15 | 0.3 |

Get your copy of the CivilWeb Pipe Flow Calculator spreadsheet including full Colebrook-White analysis now for only £20.

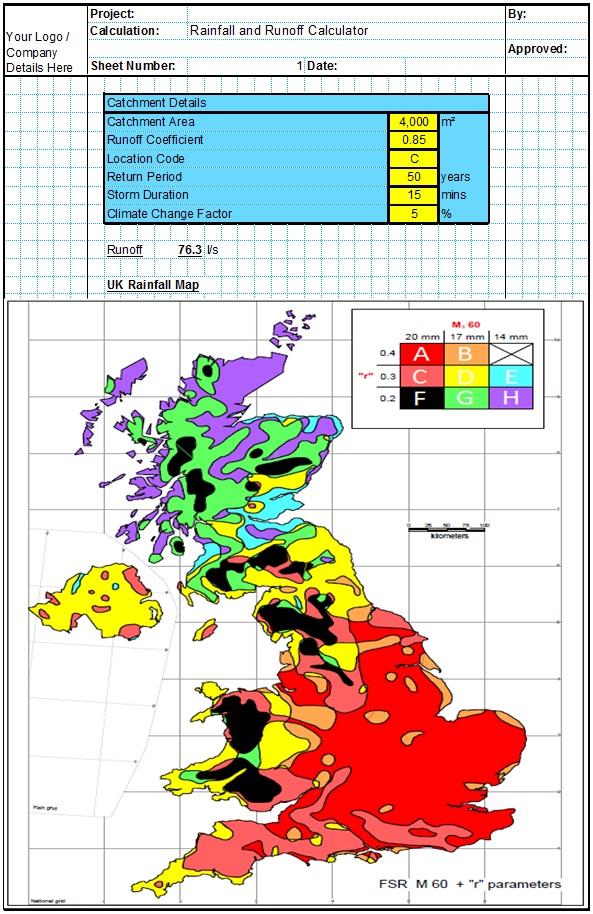

Or why not bundle the CivilWeb Pipe Flow Calculator with our Rainfall Calculator Spreadsheet for only £5 extra?

Related Spreadsheets from CivilWeb;

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 6 spreadsheet suites;

- Pipe Flow Calculator

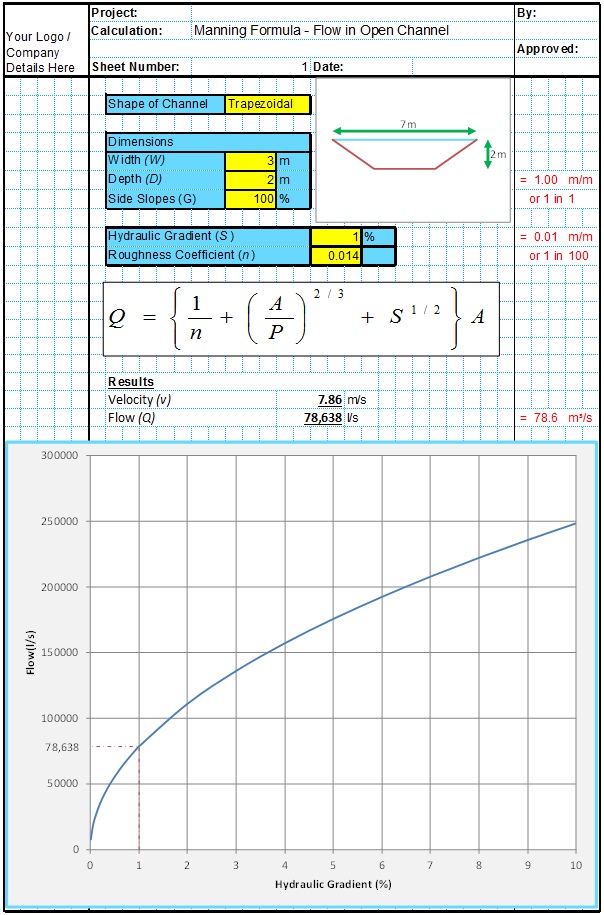

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design