Circular section pipes are by far the most commonly used shape for drainage pipes. This is because the cylindrical shape achieves the maximum area possible for the perimeter length of material. Cylindrical pipes are also easy to make and reasonably easy to store and install. Most design standards do not deal directly with other shapes.

There are however a number of alternative drainage pipe shapes which have been used in the past and which may provide some advantages in certain circumstances.

Arch Pipes

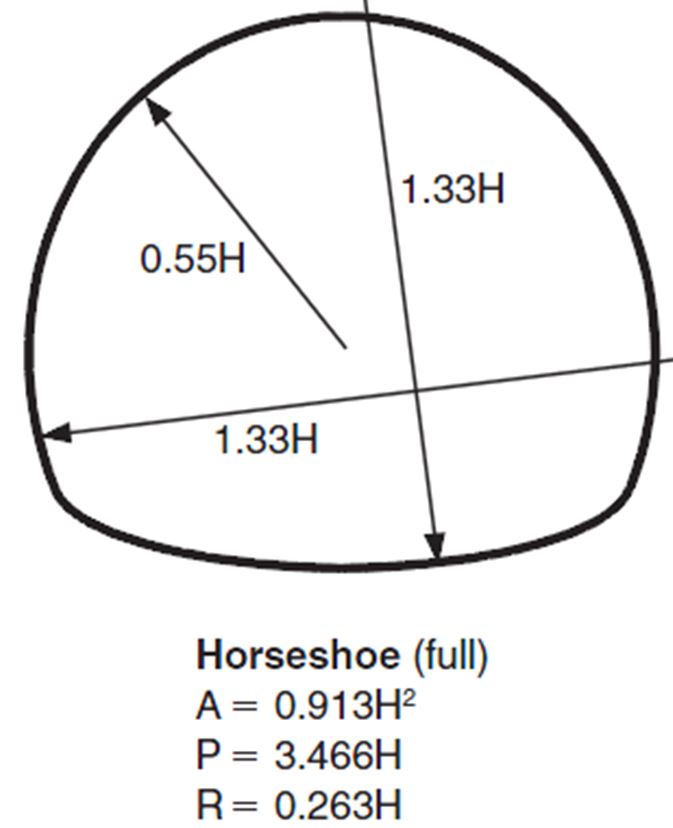

Arch section pipes (also known as horseshoe shape) are typically made of steel but can be made of concrete. They are sometimes used where there are limits to the size of the pipe as they will increase discharge by around 14% compared to a similar height circular section pipe. A diagram showing the typical dimensions and geometrical details of arch pipes is shown below;

Hydraulic Performance

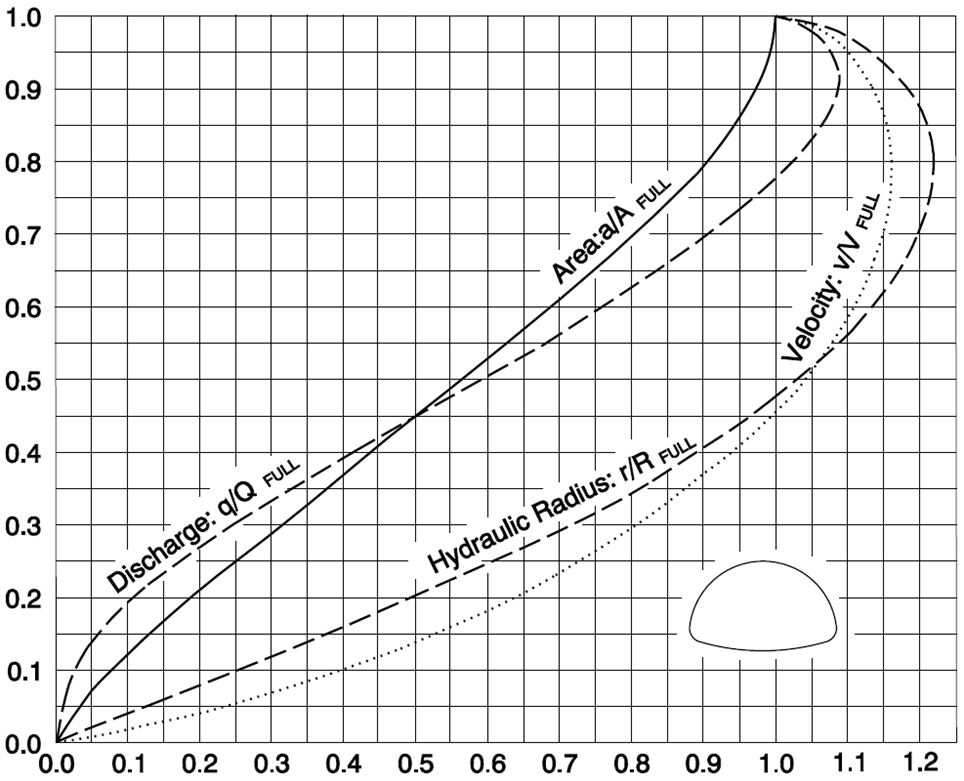

As arch section pipes are similar to circular section pipes, their hydraulic performance can be analyzed using the Colebrook-White or Manning equations. To do this we can substitute the pipe Diameter values for 4xHydraulic Radius. A diagram showing the hydraulic performance of arch pipes running partially full is shown below;

The CivilWeb Pipe Flow Calculator spreadsheet package includes the option to calculate the hydraulic performance of arch section pipes using either the Colebrook-White Formula or the Manning Formula. While these calculations are precise, they relate to a general arch section shape. Therefore the results should be checked against the manufacturer’s information if available.

Egg Shaped Pipes

Egg shaped section or ovoid pipes were commonly used in the 19th century in the UK, particularly for combined sewers with a low daily flow.

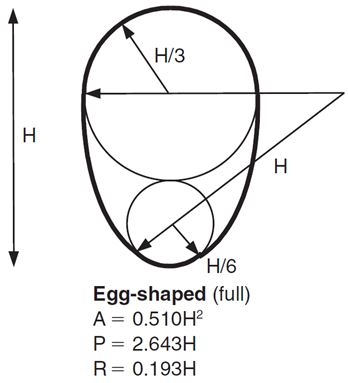

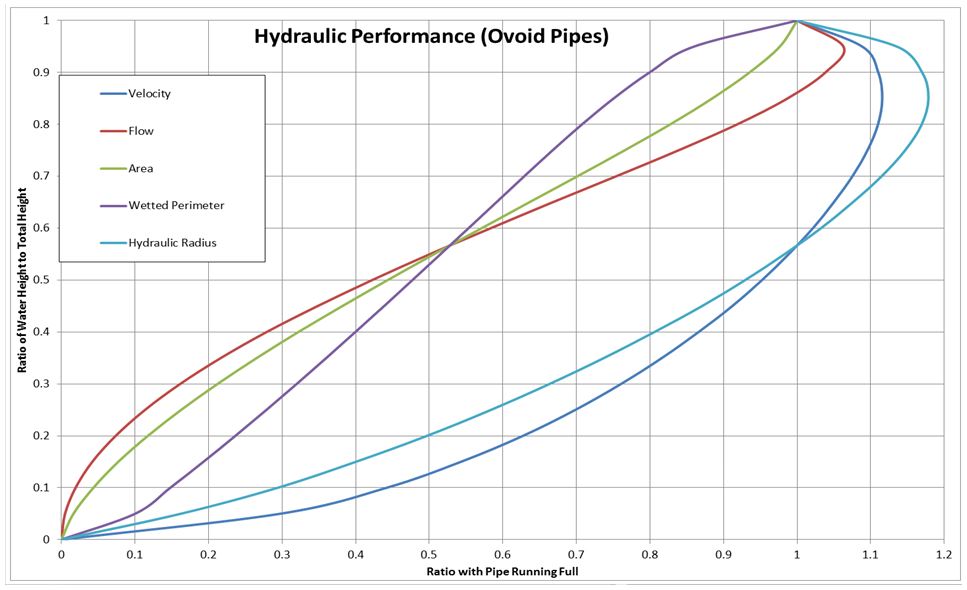

Egg shaped pipes have higher velocities at low volumes due to the shape of the bottom of the pipe and for this reason can have better self-cleansing characteristics. In some conditions this improved performance can allow pipes to be laid at shallower gradients and can offset the increased costs of the pipe compared to standard circular section pipes. A diagram showing the typical hydraulic performance of egg shaped pipes is shown below;

Egg shaped pipes can also resist higher traffic loadings than circular pipes and are much less likely to deform under load.

As the point of the egg shape is placed at the bottom, these shape pipes can be difficult to construct and can be unstable if not completed correctly. They are also more expensive to make than circular pipes, and for this reason are only used in specific circumstances.

The CivilWeb Pipe Flow Calculator spreadsheet package includes the option to calculate the hydraulic performance of egg shape section pipes using either the Colebrook-White Formula or the Manning Formula. While these calculations are precise, they relate to a general egg shape section as shown in the above diagram. Therefore the results should be checked against the manufacturer’s information if available.

Elliptical Pipes

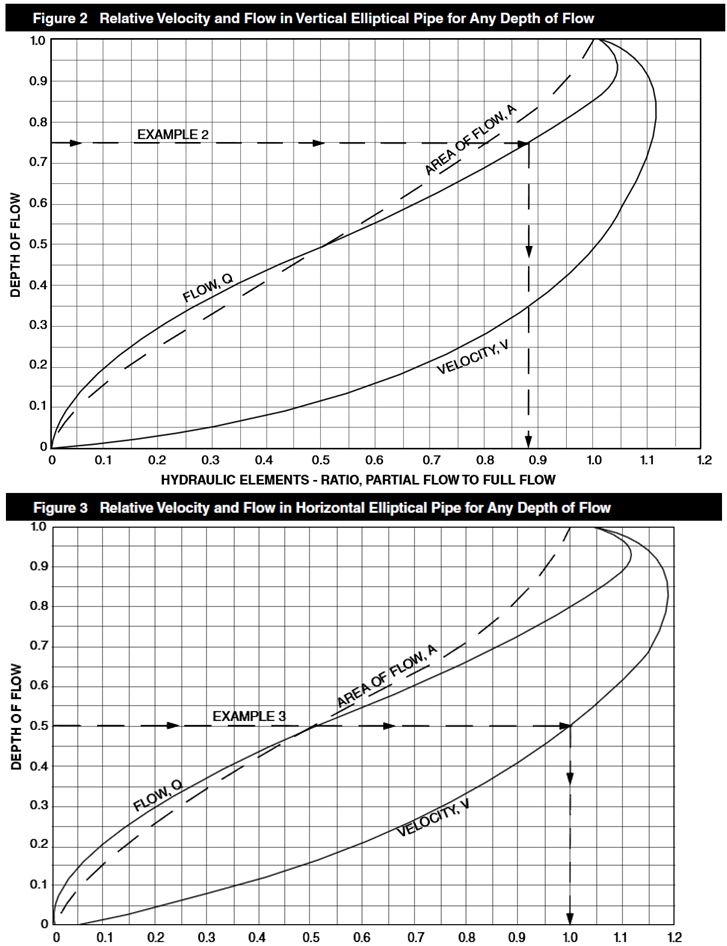

Elliptical pipes are also available. They can be installed either vertically or horizontally, with the vertical alignment offering hydraulic advantages similar to the egg shaped pipes discussed above. The horizontally laid pipes offer a better hydraulic capacity than circular pipes of the same height. This is particularly useful when there is a limit to the height available for the pipe or when there are structural reasons for keeping the pipe at a certain depth. Similarly vertically laid elliptical pipes can be used when there are horizontal restrictions on the pipe width.

Elliptical pipes can be more difficult to install than circular pipes, particularly when laid in a vertical alignment. They are more expensive to make than circular pipes but they are certainly useful in situations where either horizontal or vertical space is limited.

The CivilWeb Pipe Flow Calculator spreadsheet package includes the option to calculate the hydraulic performance of elliptical pipe laid either horizontally or vertically using either the Colebrook-White Formula or the Manning Formula. While these calculations are precise, they relate to a general elliptical shape section which may not exactly correlate to the required ellipse ratio. Therefore the results should be checked against the manufacturer’s information if available.

Two diagrams showing the typical hydraulic properties of elliptical pipes are shown below.

Non-Standard Pipe Shapes

Other pipe or conveyance shapes such as square, rectangular, U shaped or irregular shaped pipes may need to be analyzed from time to time. Where no manufacturer’s information is available, these sections hydraulic properties can be estimated using the Colebrook-White or Manning Formulas. The area and perimeter of the section can be used to calculate the hydraulic radius which can then be inserted into the formulas, a value of 4xR replaces the Diameter (D). As long as the section is basically circular with no re-entrant vertices, the formulas will give a reasonable estimate of the velocity and flow through the pipe.

The CivilWeb Pipe Flow Calculator spreadsheet package includes the option to calculate the hydraulic performance of any shaped pipe using either the Colebrook-White Formula or the Manning Formula.

Get your copy of the CivilWeb Pipe Flow Calculator spreadsheet including arch, egg-shaped and elliptical pipe design now for only £20.

Or why not bundle the CivilWeb Pipe Flow Calculator with our Rainfall Calculator Spreadsheet for only £5 extra?

Related Spreadsheets from CivilWeb;

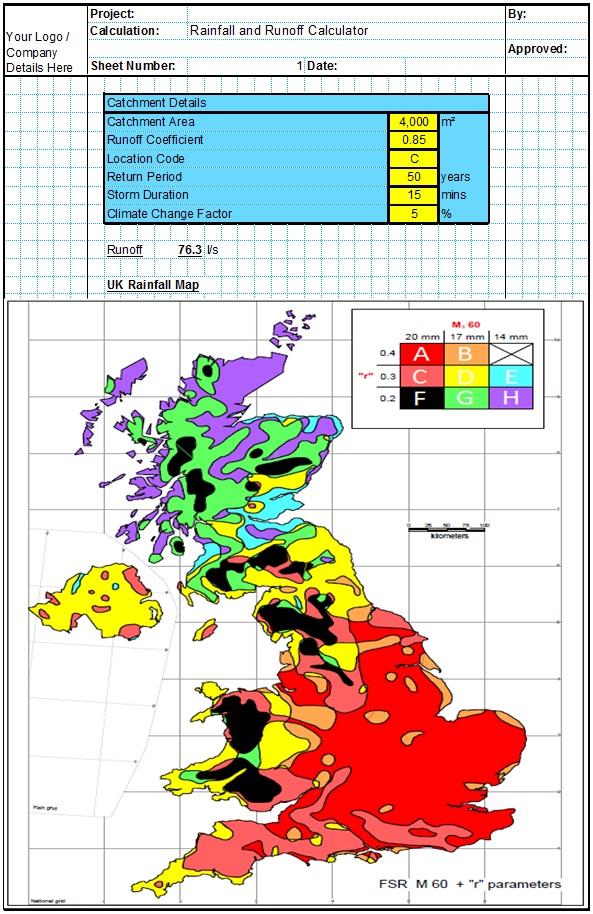

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 6 spreadsheet suites;

- Pipe Flow Calculator

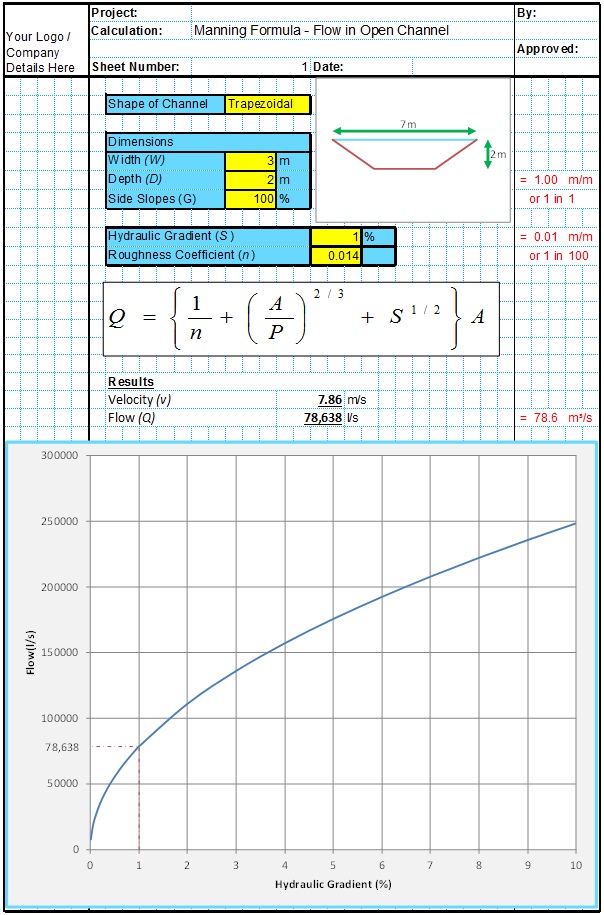

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design