Runoff from a construction site is often heavily laden with sediments and for this reason construction site runoff should not be allowed to enter a soakaway or other drainage system. If runoff has entered the soakaway during the construction phase it is essential that the soakaway is thoroughly cleaned and the sediments removed to prevent the soakaway from becoming clogged with sediments. If some runoff must be dealt with by the soakaway during the construction phase it is essential that suitable sediment interception methods are employed, and that these are all cleaned or re-mediated at the end of the project. Temporary silt fences or sediment traps can be effective temporary measures. Alternatively a grass strip could be left in place to act as a filter strip where possible.

If a soakaway needs to be utilised during the construction phase to treat runoff, the runoff can first be captured and put through a mobile silt catchment system such as a Silt Buster. This will remove the silt from the runoff allowing it to be discharged through the soakaway.

It is also advisable to prevent large amounts of construction runoff from travelling over soils which are going to be used as infiltration materials for a proposed soakaway to prevent sediments from infiltrating into the soils and reducing its infiltration rate. Alternatively silt fences or straw bale barriers can be used to reduce the sediment load of any runoff traversing the soil during construction.

Straw bales can be placed at the base of a slope to trap some of the sediment being eroded from the slope progressing onto the rest of the site. Alternatively they could be installed around a proposed soakaway site to protect this specific site from sediments laden runoff during construction. They can also be installed around completed inlets to prevent sediments from entering a completed drainage system linked to a soakaway during the construction phase. They are temporary in nature and generally will become fully clogged in a few weeks or months. For larger sites diversion ditches and sedimentation basins may be required.

Silt Fences for Soakaways

A silt fence is a woven geotextile material which acts in the same way to remove some of the sediment from construction site runoff. Similar to straw bales the silt fence should be installed at the base of a disturbed slope or around a proposed soakaway site. A silt fence will usually last longer than straw bales if properly maintained. Neither straw bales or silt fences are appropriate where concentrated flow is expected. A more robust method of sediment removal will be required where concentrated flows are expected.

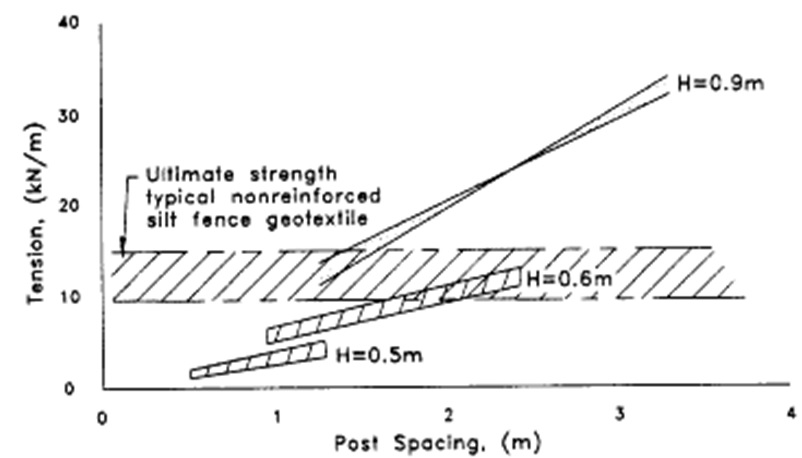

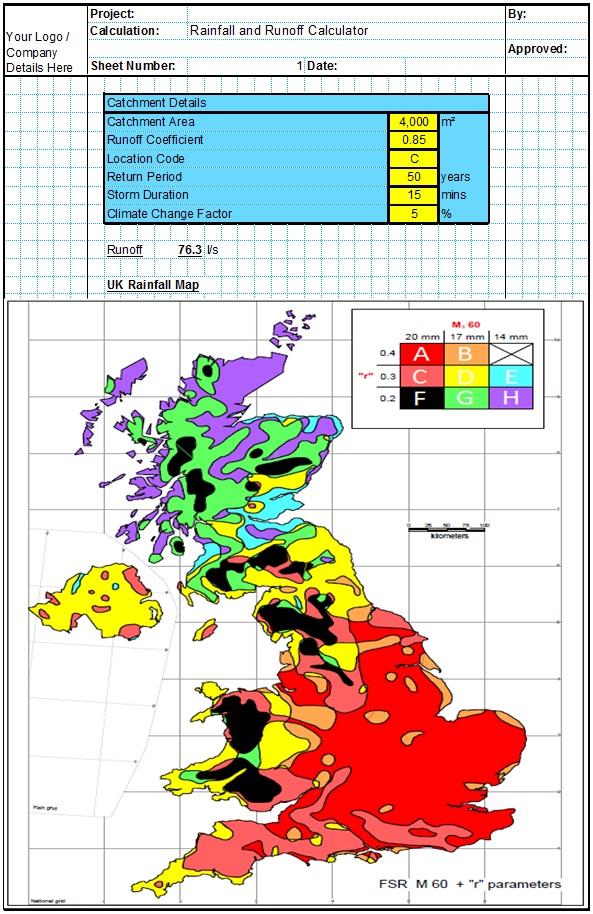

The design of a silt fence follows the following procedure. First the volume of water is estimated from rainfall and runoff models. The CivilWeb Rainfall & Runoff Calculator includes some suitable models for estimating site runoff. Next the volume of sediments must be estimated. This is used to size the sediment storage area behind the silt fence. This depends on the erodibility of the soils and the intensity of the rainfall. Allowances must be made for the level of vegetation cover and slope length and steepness. Next the geotextile can be selected. The geotextile must be permeable enough to allow the design storm runoff to percolate through without overtopping the geotextile. The geotextile must also be strong enough to retain the pooled stored water behind the fence. This is dependant on the spacing of the posts or supports. The following two charts can be used to estimate the required geotextile strength.

The silt fence will usually be around 600mm-800mm high. The silt fence should be installed on a level contour as far as practical. At the ends of the fence they can be turned uphill to prevent water from running around the silt fence.

Silt Fence Installation

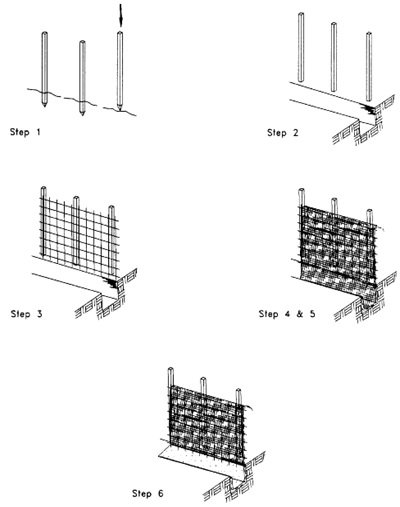

The installation will generally follow the below process;

- The posts are installed first. The posts are usually either wood or steel and are typically installed at between 0.5m and 3.0m spacing. Posts are generally driven around 600mm into the ground, depending on the expected loads and post spacings.

- Then a trench is dug at the base. The bottom 150mm of geotextile must be buried to prevent any runoff from flowing underneath the silt fence.

- Then any reinforcing wire or mesh is installed to the posts.

- Next the geotextile is fixed to the posts, usually using staples or wire. Care must be taken to prevent the geotextile from tearing or puncturing during installation, particularly when fixing the geotextile to the posts.

- The trench should be carefully backfilled and compacted to prevent any scouring.

There are also measures which should be taken onsite to minimise the potential for site erosion, reducing the sediment loads carried by site runoff. Vegetation should be left in place for as long as practical and then disturbed areas should be left exposed for as short a time as possible. Care should also be taken to avoid erosion from concentrated flows of rainwater. This includes preventing large volumes of water from running down steep slopes, particularly where these slopes are not protected with vegetation during the construction process. Any soil stockpiles should be protected with vegetation, erosion control fabrics or stabilised if left onsite for a long period of time.

Related Spreadsheets from CivilWeb;

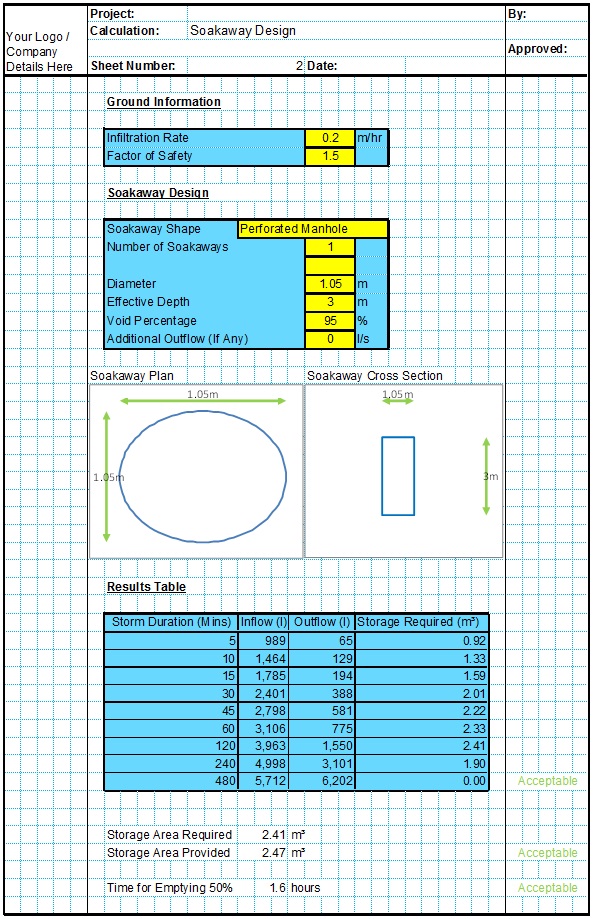

Soakaway Design Spreadsheet

This spreadsheet calculates the requirements for a soakaway system and assists the user to design a suitable system.

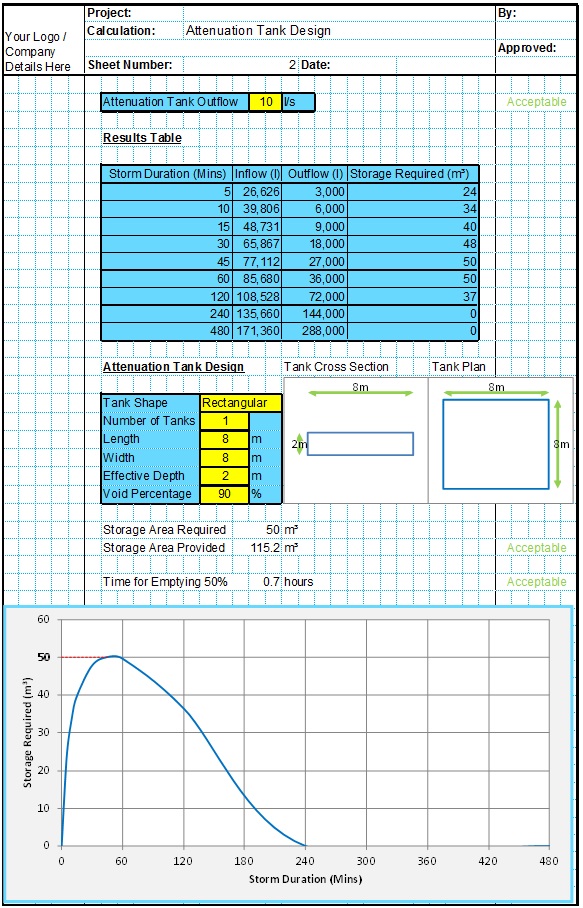

Attenuation Design Spreadsheet

This spreadsheet calculates the requirements for a attenuation system and assists the user to design a suitable system.

Runoff Calculator Spreadsheet

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

Full Drainage Design Suite

Full drainage design suite (50% Discount) including 7 spreadsheets;

- Colebrook White Pipe Design

- Manning Pipe Design

- Manning Open Channel Design

- Linear Drainage Design

- Runoff Calculator

- Attenuation Design

- Soakaway Design