In order to ensure that the french drain performs as required, it is important that the french drain installation process is carried out correctly. French drain installation is not a particularly complex undertaking and any civils or ground works contractor should be able to build a french drain correctly. The performance of the completed drain is sensitive to the quality of the french drain construction so care must be taken that the french drain is installed correctly.

The most important consideration when building a french drain is to ensure that the drain functions as designed. This can be achieved by undertaking the installation of the drain in accordance with the design drawings and specification. Further information on french drain details can be found in our French Drain Details post.

It is important that all components of the french drain are kept clean and in good condition before and during installation. This includes the geotextile filter fabric, filter material and perforated pipe which all must be kept clear of mud and debris onsite. Any mud or debris on the geotextile or within the filter material will compromise the performance of the completed french drain by inhibiting the permeability of the materials. For this reason sediment control is an important part of filter drain installation.

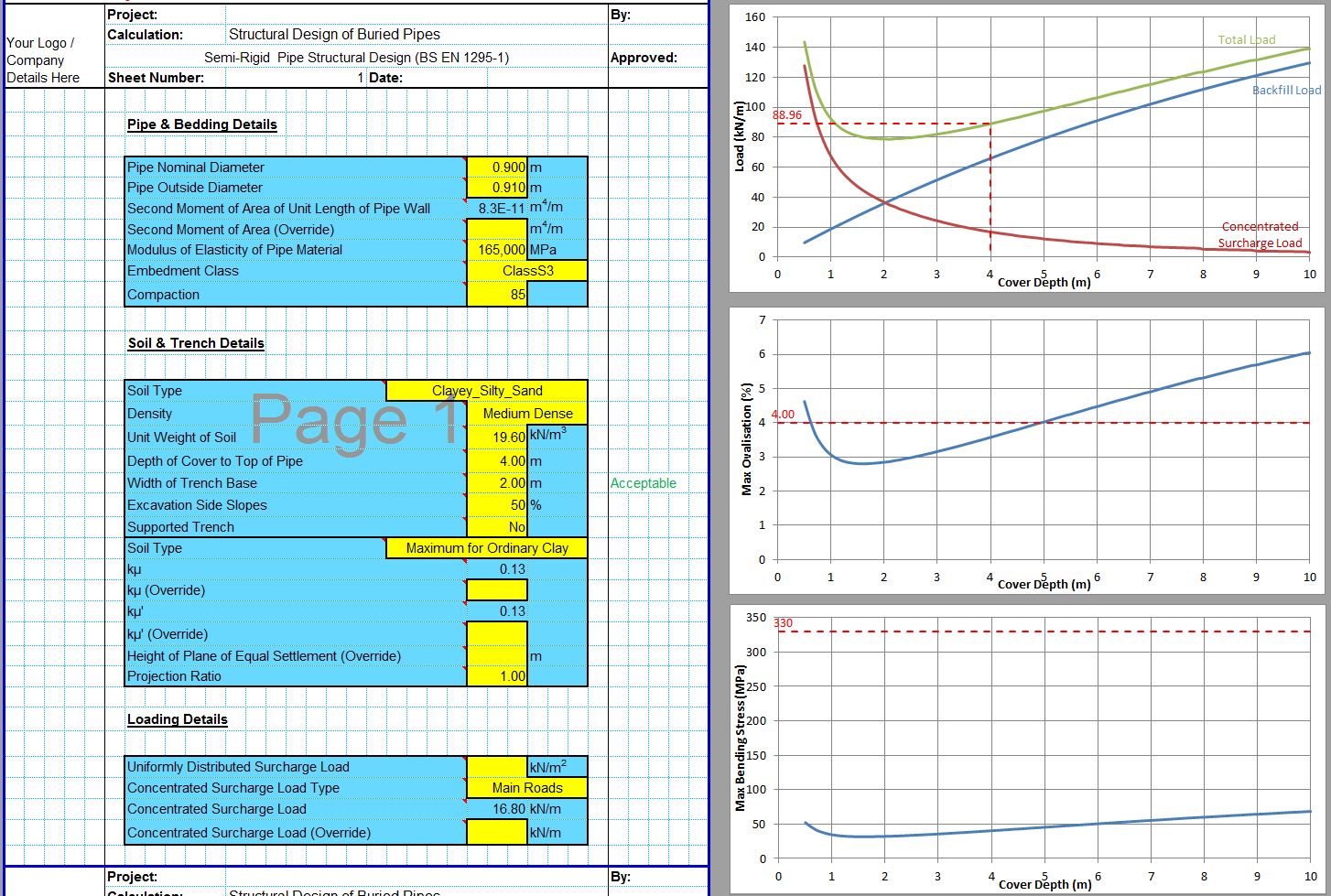

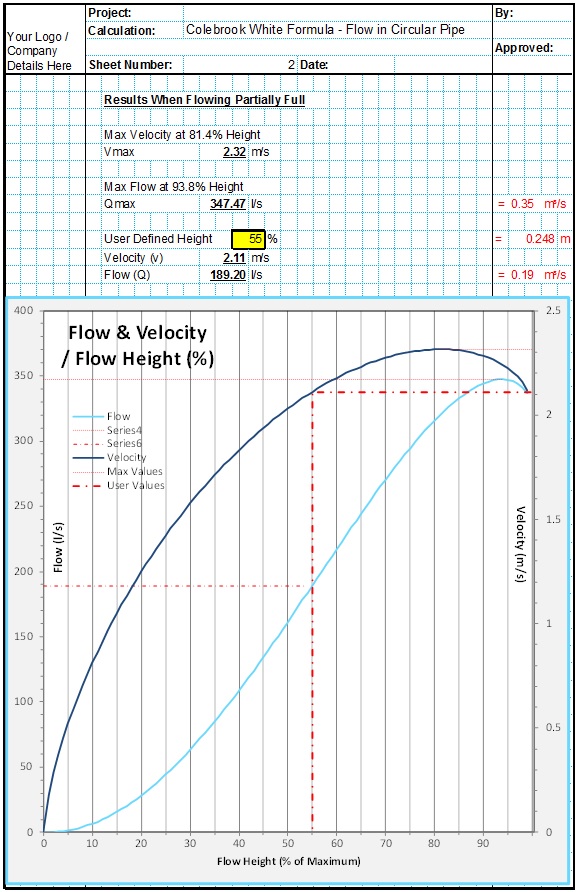

Where contamination is suspected the design of the french drain system can be modified by amending the expected permeability rates of the compromised components. The CivilWeb French Drain Design spreadsheet can be used to check that the french drain design is adequate.

Other general french drain construction concerns include ensuring the excavation is undertaken safely and correctly, the french drain filter fabric is installed carefully and the filter material is installed correctly. Construction inspections are an essential quality control tool which the designer can use to ensure that the french drain is installed correctly and will function as designed.

Digging a French Drain

The french drain trench must be sufficiently wide to allow the installation of the perforated pipe and the bedding material to the sides of the pipe. A calculator tool is included with the CivilWeb French Drain Design spreadsheet to check that minimum trench widths are in accordance with BS EN 1610.

The trench must also be wide enough to accept the required volume of runoff water from the design storm. Further information on french drain trench width is included in our French Drain Width post.

Care should be taken when digging a french drain trench through clay soils. Clay soils can become unstable in wet conditions and there is a risk that the sides of the trench can become smeared when excavated using mechanical plant and equipment. Further information is included in our French Drain in Clay post.

The depth of the french drain trench should be deep enough to protect the perforated pipe from any expected imposed loadings from the surface, and to maintain a consistent gradient for the perforated pipe. This is explained in further detail in our French Drain Depth post.

Laying Perforated Drainage Pipe

The bottom of the french drain trench should be smooth, firm and free of rocks or other hollows or protrusions. The trench bottom should be shaped to allow the secure bedding of the perforated pipes.

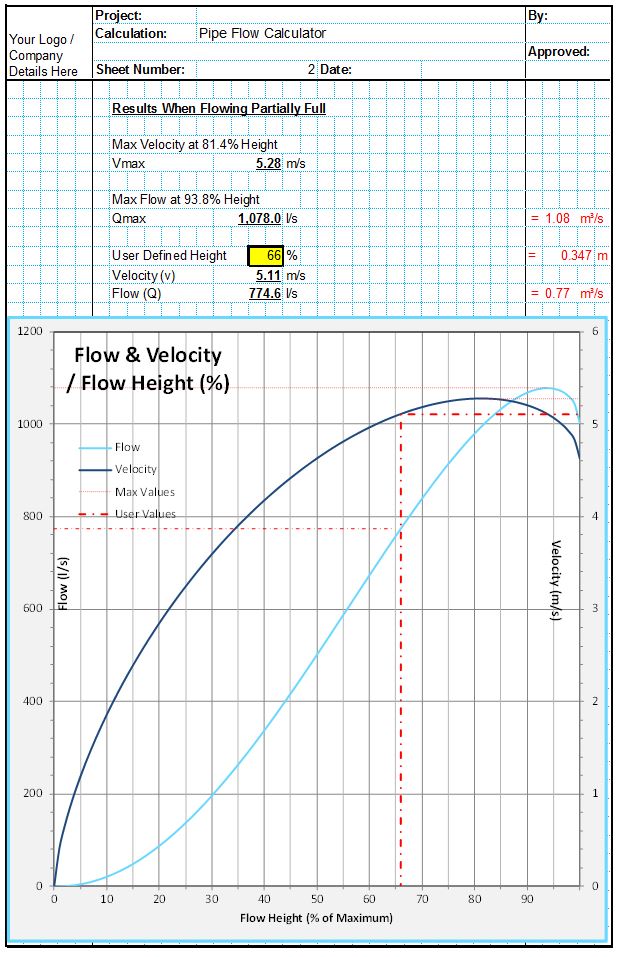

Laser grade control systems can be used to ensure the bottom of the trench and the perforated drainage pipes conform to the correct gradients. Care should be taken that any laser devices are used properly and safely. Pipes should not be laid with backfalls even for small lengths of the run. A consistent grade is very important for the performance of the perforated pipe. Further information is contained in our Perforated Pipe Design post.

Unperforated pipes should be installed in places where ingress from tree roots is expected. Unperforated pipes should also be used where there is a risk of soil erosion, scour of other harmful effects of infiltrating runoff.

Avoid dropping large or sharp pieces of the backfill material directly onto the pipe as this can cause damage.

Other Underground Services

The length and depth of french drains means that they are likely to encounter underground services where any exist. Known existing services must be located and marked onsite before any excavation works commence. The full area of the excavation must also be checked using a service detection device such as a cable avoidance tool (CAT) or similar. Service plans can be provided by the service providers.

Where there are any known services or where the service detector indicates there may be an unknown service, these must be uncovered using hand dig methods utilizing isolated hand digging equipment. Any service affected by the filter drain must be protected and supported throughout the works.

Sediment Control

Muddy or silty runoff is common on large construction sites including highway works. Where french drains are to be constructed as part of the works, care must be taken to prevent this construction runoff from entering the french drain system. Silt fences and similar devices can be used to contain or divert construction site runoff away from the french drain or the proposed french drain location. Further information is included in our Silt Fences post.

French drains and any other drainage systems must also be protected from any potential sources of pollution or contamination which may be present during the construction works.

Programming the French Drain Installation

On large highway or other construction projects it may seem natural to complete the french drains during the earthworks phase of the project as the heavy plant is already onsite.If the french drain construction is complete early in the project life there is a significant risk of the french drain becoming damaged or clogged with construction runoff during the course of the project.

Where infiltration into surrounding soils is included in the french drain design, there is also the risk that large plant movements will damage or compact the surrounding soils reducing their effective infiltration rate. If infiltration rate testing is completed before the project starts this could lead to the french drain being under designed.

This can be avoided by completing the french drain towards the end of the project.

Construction Inspections

Regular inspections of the french drain installation should be undertaken to ensure that the works are progressing in accordance with the detail drawings and the specification. This can be in a similar format and content as the construction inspections example given on our Soakaway Construction Inspections post.

Get your copy of the CivilWeb French Drain Design spreadsheet now for only £20.

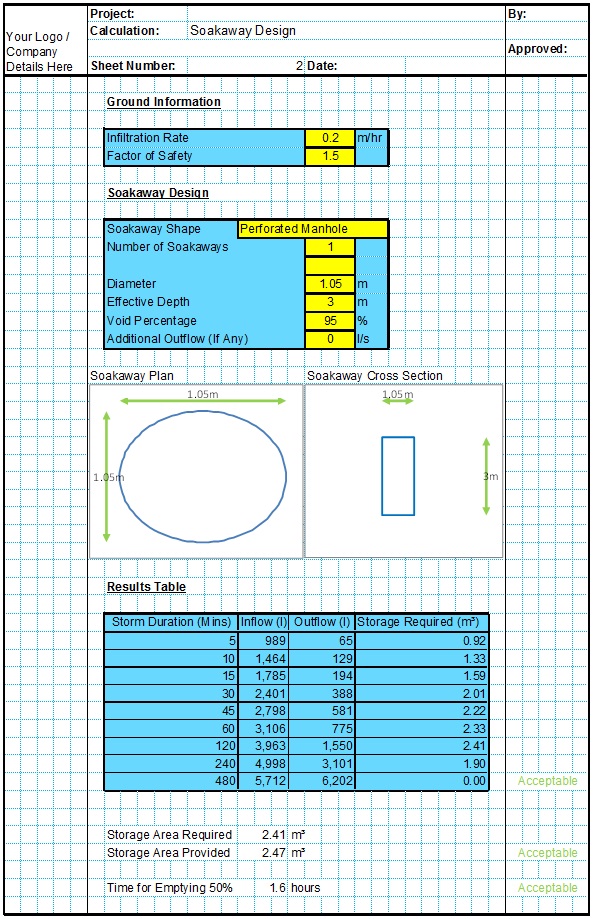

Or why not bundle with the CivilWeb Soakaway Design spreadsheet for only £5 extra?

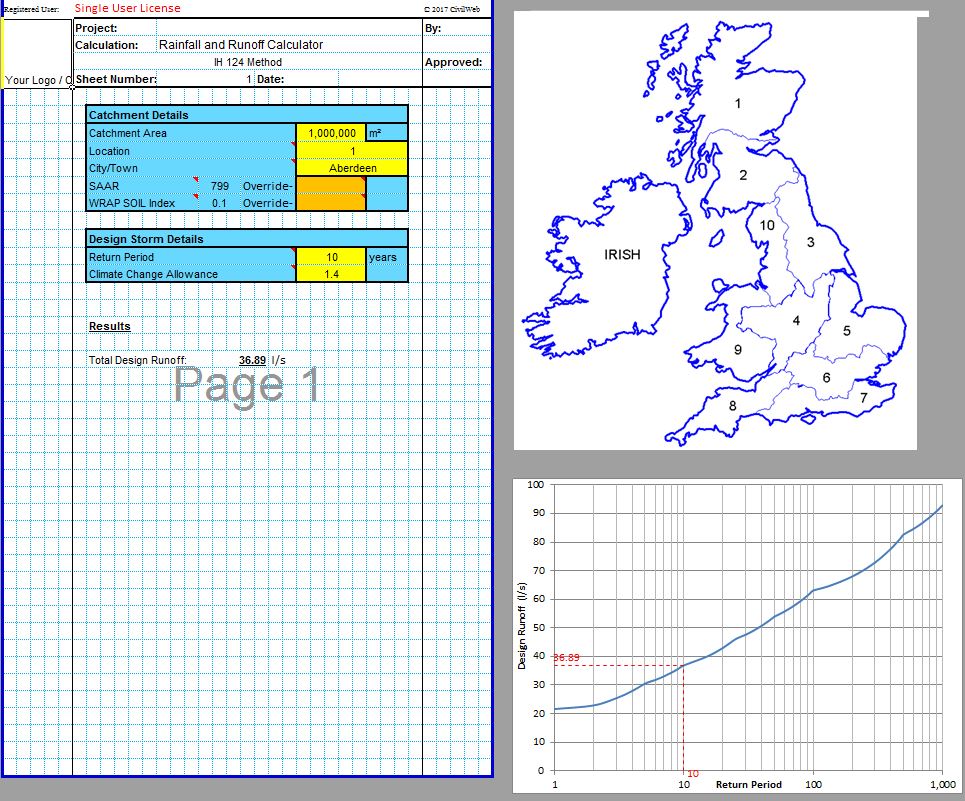

Or save £50 by buying our full Drainage Design Suite including all our drainage design spreadsheets.

Download Free Trial Version

To try out a fully functional free trial version of this software, please Click Here or enter your email address below to sign up to our newsletter.