The CivilWeb Concrete Mix Design Spreadsheet is an easy to use spreadsheet which can be used to calculate the precise concrete mix requirements to suit a specification. The spreadsheet completes all the calculations in accordance with the BRE Normal Concrete Mix Design guidance. The spreadsheet allows the designer to specify all the requirements for the concrete mix such as strength and workability, and then the spreadsheet calculates the required cement content, water/cement ratio and aggregate requirements in order to meet all the specification requirements. The CivilWeb Concrete Mix Design Spreadsheet allows the designer to complete a fully compliant concrete mix design for any normal concrete specification in minutes, saving hours of detailed calculations for every concrete mix design.

The CivilWeb Concrete Mix Design Spreadsheet can be purchased at the bottom of this page for only £20. Alternatively this spreadsheet is included in the Concrete Design Suite which includes all of our reinforced concrete design spreadsheets. This is our best value design bundle and can be purchased at the bottom of this page for only £50.

Concrete Mix Design

Concrete mix design can be a complex and time consuming process. Concrete is a very complex composite material consisting mostly of cement, water, aggregates and other property altering additives. The design of a concrete mix is extremely complicated as changing the volume or properties of any one component will affect all the others.

Concrete specifications are also complex and often require the designer to create a concrete with several different properties including strength, workability, density and cost. In some cases these are contradictory, for example strength and workability usually work against each other. Satisfying two or more different specification requirements can lead to the designer having to complete the calculations many times over until a balance is achieved.

This can make concrete mix design seem daunting to designers who do not complete the process regularly. However after many years of development the Building Research Establishment were able to derive a relatively straightforward standard procedure for the design of common concrete mixes. This was published in the Design of Normal Concrete Mixes document in the 1970s and 1980s. This remains the most commonly used method of designing concrete mixes in the UK.

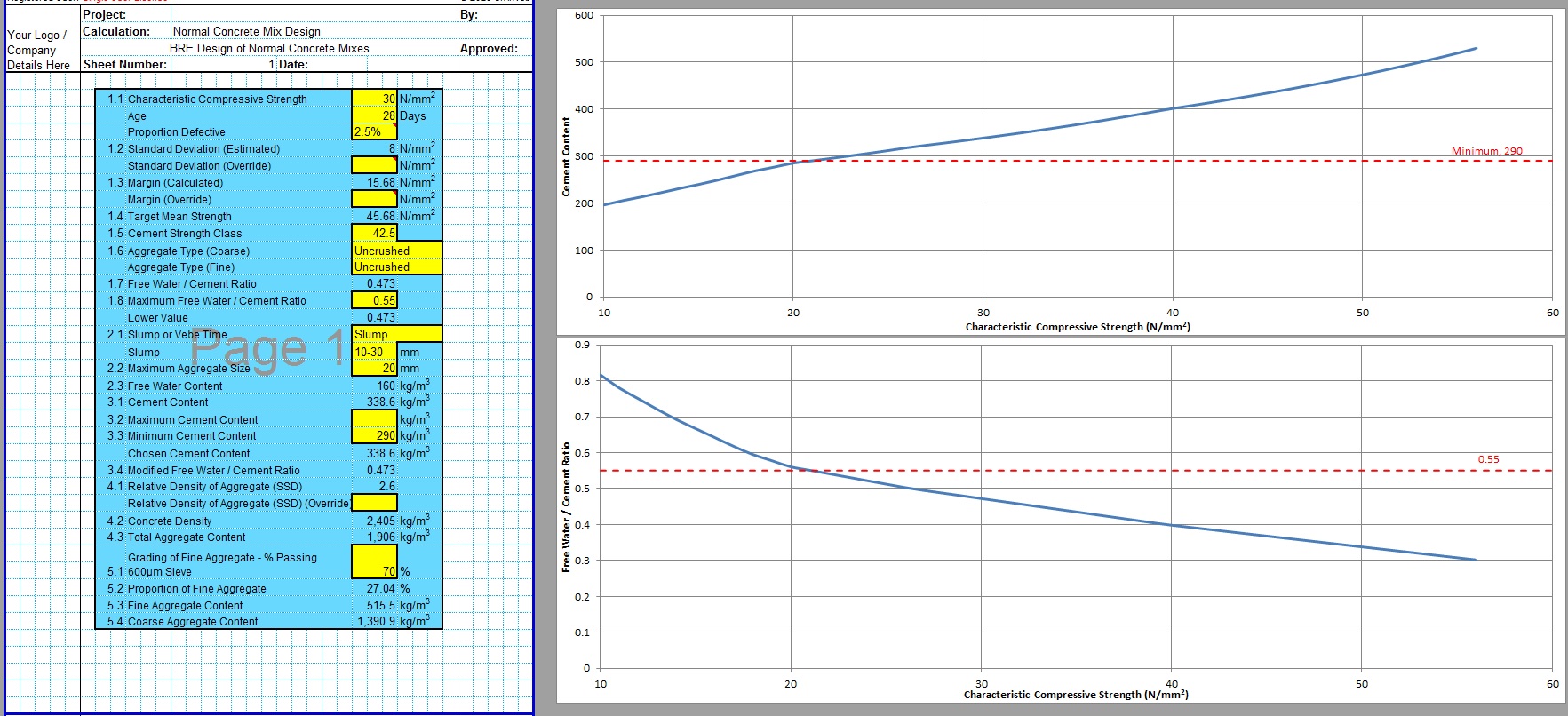

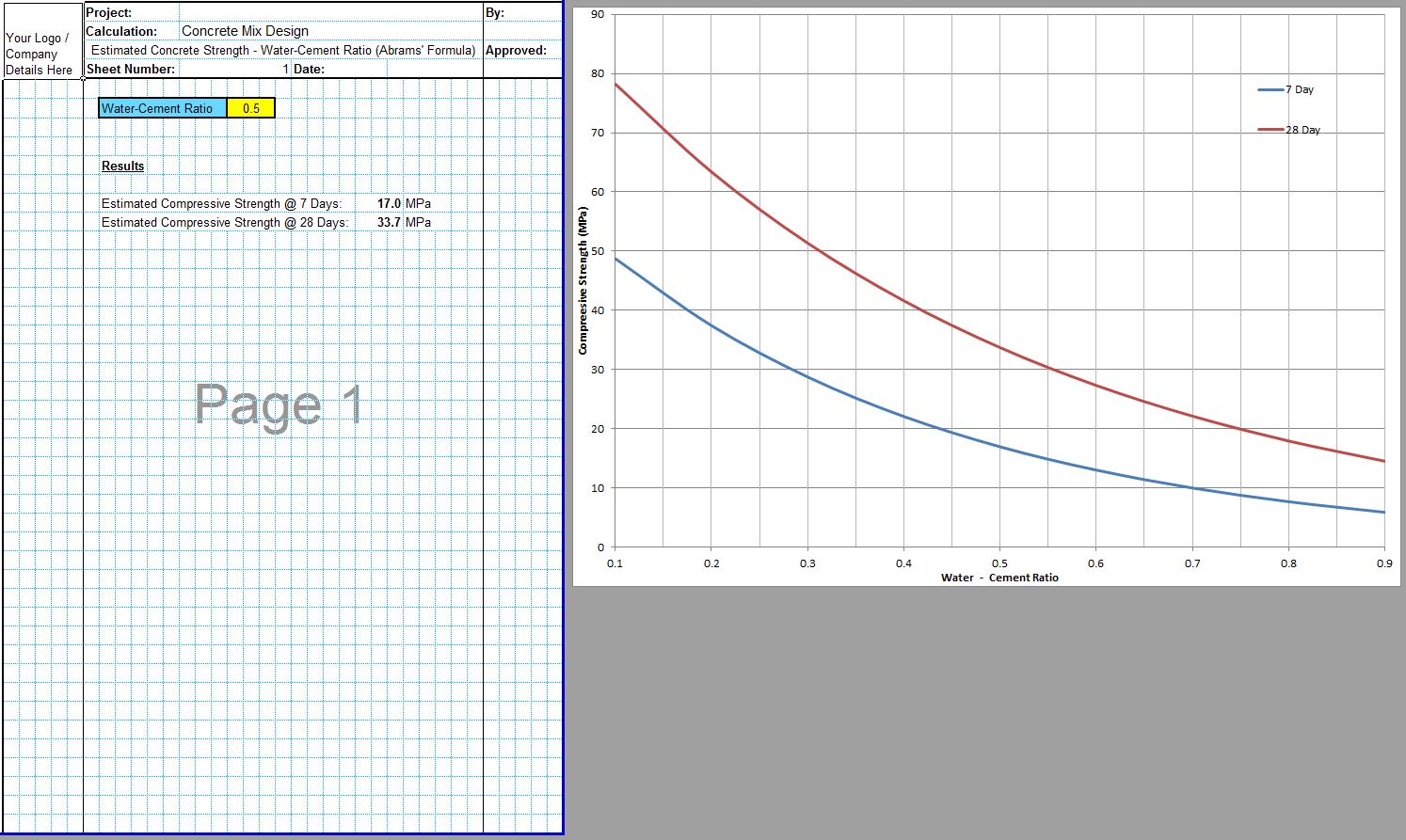

The concrete mix design process consists of 5 stages. First the designer inputs the target compressive strength for the concrete mix design along with the cement type and aggregate types. The concrete mix design excel sheet then calculates the required water-cement ratio for the mix. Next in phase two the designer inputs the required slump or vebe time. The concrete mix design calculator excel sheet then uses this to calculate the required free water content to achieve this slump or vebe time.

Phase three requires the designer to input any maximum or minimum required cement contents. The concrete mix design excel sheet then calculates the required cement content and adjusts it to suit the maximum and minimum cement requirements. In phase four the designer inputs the density of the aggregate and the concrete mix design excel sheet uses this to calculate the density of the concrete mix.

Finally for phase five the designer inputs the percentage of fine aggregate. The concrete mix design excel sheet then calculates the quantities of fine and coarse aggregates. The spreadsheet then presents the designer with the required quantities of cement, water, fine aggregates and coarse aggregates in order to achieve the required strength and workability.

Concrete Mix Design Spreadsheet - Inputs

The CivilWeb Concrete Mix Design Spreadsheet Excel allows the designer to complete the design of a concrete mix to suit a number of different specifications. The spreadsheet uses a small number of mandatory fields such as target characteristic compressive strength, target slump and aggregate types which should be known before the concrete mix design begins. In most cases these mandatory fields are the most important parts of a concrete mix specification.

Next the CivilWeb Concrete Mix Design Spreadsheet Excel allows the designer to input a number of optional specification fields such as standard deviation, margin and maximum and minimum cement contents. These fields can be known in advance. For example the standard deviation may be known if some testing of concrete mixes has already been done and the cement content limits may be part of the specification. If these optional fields are filled, the spreadsheet automatically alters the concrete mix design xls to suit the input values. If the optional fields are not filled, the spreadsheet calculates the optimum value for these fields based on the other specification requirements.

In some cases the specification can present an impossible contradiction. This happens sometimes when the maximum or minimum cement content clashes with the target characteristic compressive strength. Cement content is the most important factor determining the strength of the concrete mix and if a high strength and low cement content are both specified, this can lead to a contradiction. The CivilWeb Concrete Mix Design excel sheet will resolve such clashing specification clauses as far as possible using other factors, but where this is impossible the spreadsheet will advise on the required cement content and highlight where this clashes with the specification.

The CivilWeb Concrete Mix Design excel sheet completes all the calculations required and presents the designer with a complete concrete mix design which complies with all the input specification requirements. The spreadsheet details the required volumes of cement, water and aggregates in order to meet the specification which can be sent straight to a plant for production of a trial mix.

The CivilWeb Concrete Mix Design excel sheet also includes special mix design spreadsheets for air entrained concrete and for concrete mixes containing ground granulated blast furnace slag (GGBS) or fly ash mineral additives. These commonly used additives affect the mix design, particularly the strength gain.

CivilWeb Concrete Mix Design Spreadsheet

The CivilWeb Concrete Mix Design Spreadsheet can be used to design any normal concrete mix in accordance with the BRE Normal Concrete Mix Design guidelines. The spreadsheet also designs air entrained concrete mixes or mixes containing GGBS or fly ash. The spreadsheet is laid out in a very simple fashion with explanations for which inputs are required and which are optional. This easy to use layout allows the designer to complete a concrete mix design to suit any specification in minutes, saving hours of iterative calculations.

Buy the CivilWeb Concrete Mix Design Spreadsheet now for only £20.

Or why not buy our best value bundle, the full CivilWeb RCC Design Suite which includes all of our concrete design spreadsheets for only £50, a saving of over 80%.

Download Free Trial Version

To try out a fully functional free trial version of this software, please enter your email address below to sign up to our newsletter.