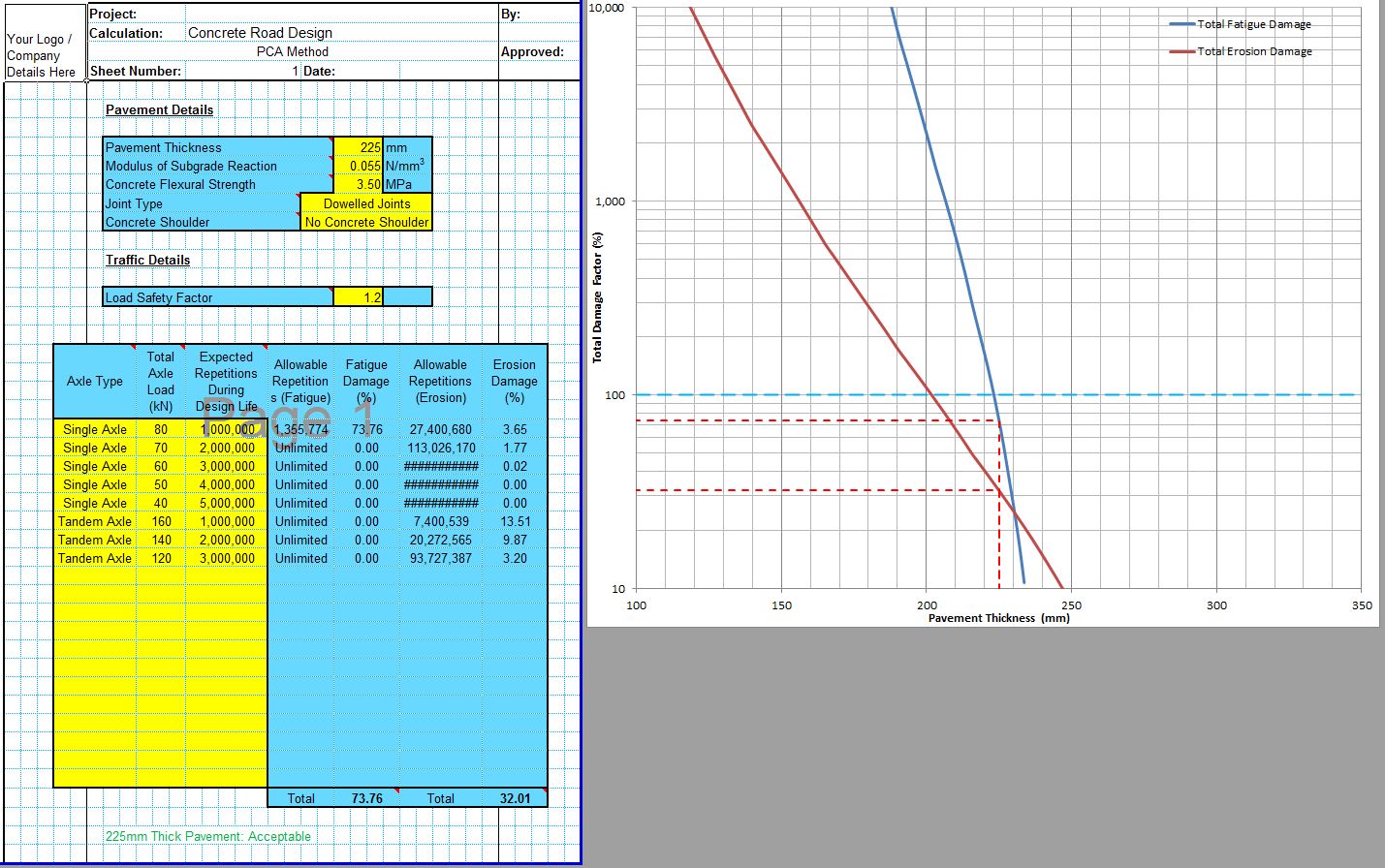

The CivilWeb AASHTO Rigid Pavement Design Spreadsheet completes the design of concrete roads or pavements in accordance with AASHTO 1998. It allows compliant concrete pavement designs to be completed in minutes with our unique design analysis tools showing the designer at a glance the optimum concrete pavement thickness.

The CivilWeb AASHTO Rigid Pavement Design Spreadsheet includes design modules for AASHTO 1986, 1998 supplement and a faulting check in accordance with AASHTO 1998. It also comes preloaded with climate data for major urban centres in every US state, while a separate module allows the designer to specify climate data making the AASHTO method suitable for any location worldwide.

The CivilWeb AASHTO Rigid Pavement Design Spreadsheet can be purchased further down this page for just £10. Alternatively the AASHTO design spreadsheet is included in the CivilWeb Rigid Pavement Design Spreadsheet Suite which includes 11 different pavement design methods along with a number of other useful design tools including concrete flexural strength calculators. Follow the above link for full details.

AASHTO 1993 Rigid Pavement Design

The American Association of Highway Transport Officials (AASHTO) has published a number of design methods for both flexible and rigid pavements based on a large experimental study of pavement performance called the AASHTO Road Test.

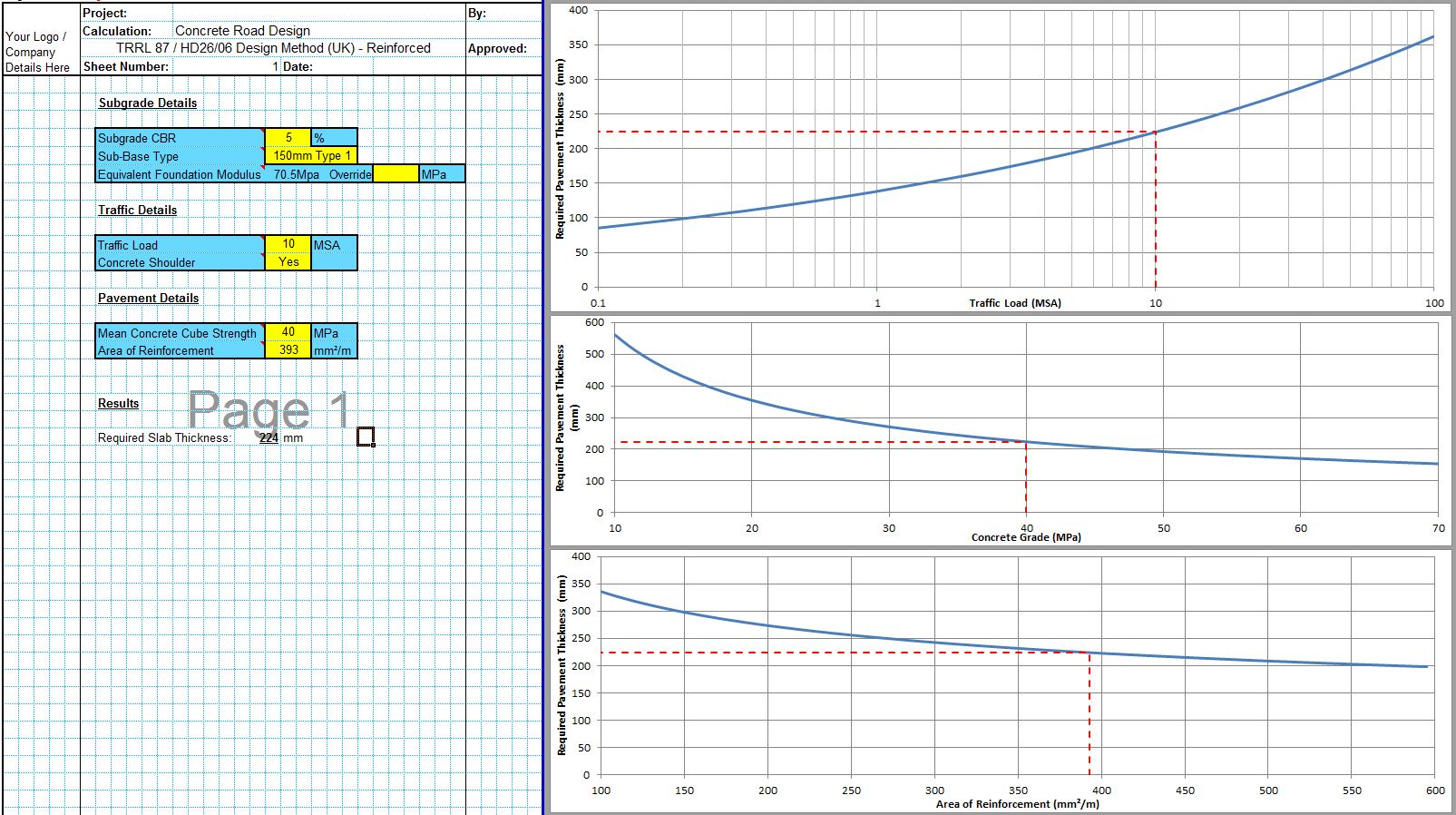

The latest AASHTO method based on the AASHTO Road Test was published in 1993. This has since been superseded by a much more complex mechanistic design procedure known as the Mechanistic-Empirical Design Guide (MEDG). However, the AASHTO 1993 rigid pavement design model is still commonly used in many parts of the world and is very useful as a simple tool for evaluating required concrete road thicknesses at preliminary stage.

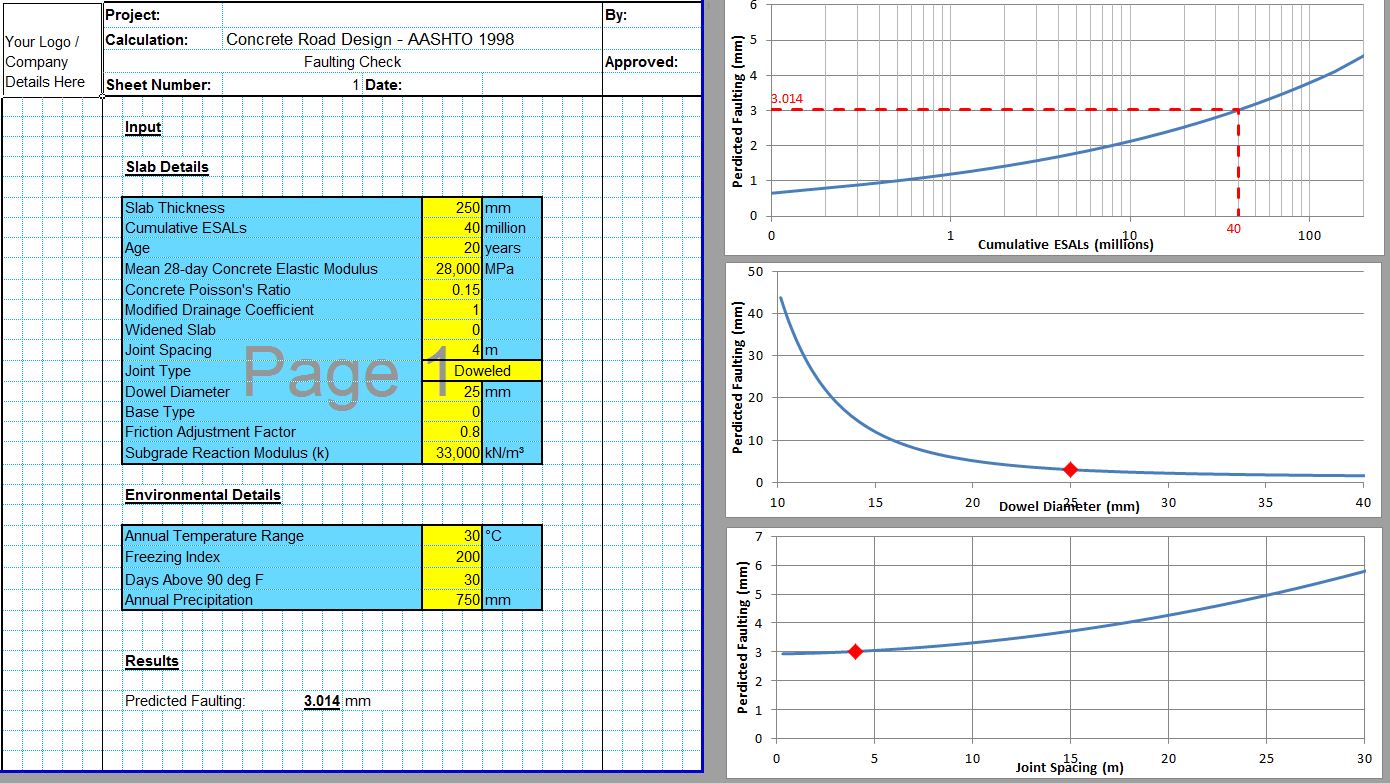

AASHTO 1998 Rigid Pavement Design

The AASHTO 1993 rigid pavement design guide was updated in 1998 with a supplement improving the method for design of concrete pavements. This time the method was not based upon data obtained from the AASHTO Road Test but on the LTPP database NCHRP project 1-30. The updated 1998 procedure works in a similar manner to the 1993 procedure but includes for the effects of joint spacing.

The AASHTO 1998 concrete pavement design Supplement included an updated design procedure for concrete pavements which included for the effects of climate and for the effects of joint spacings. As such this was a great improvement on the original 1993 method and it is the 1998 Supplement method which is most applicable to designing concrete roads. For this reason it is the AASHTO 1998 supplement which powers the CivilWeb AASHTO Rigid Pavement Design Spreadsheet.

AASHTO Rigid Pavement Design Calculations

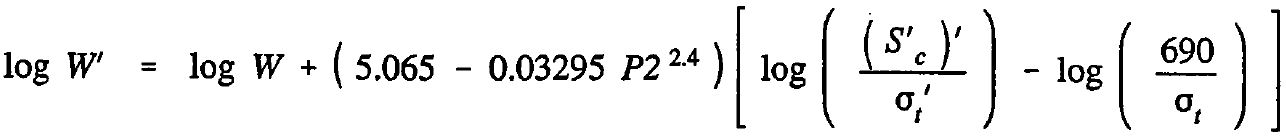

The AASHTO 1998 concrete pavement design supplement uses the following equation to calculate the number of standard 80kN axles the pavement can carry before failure. This equation assumes a 50% reliability where W’ is the number of standard axles for the traffic lane considered.

Log W

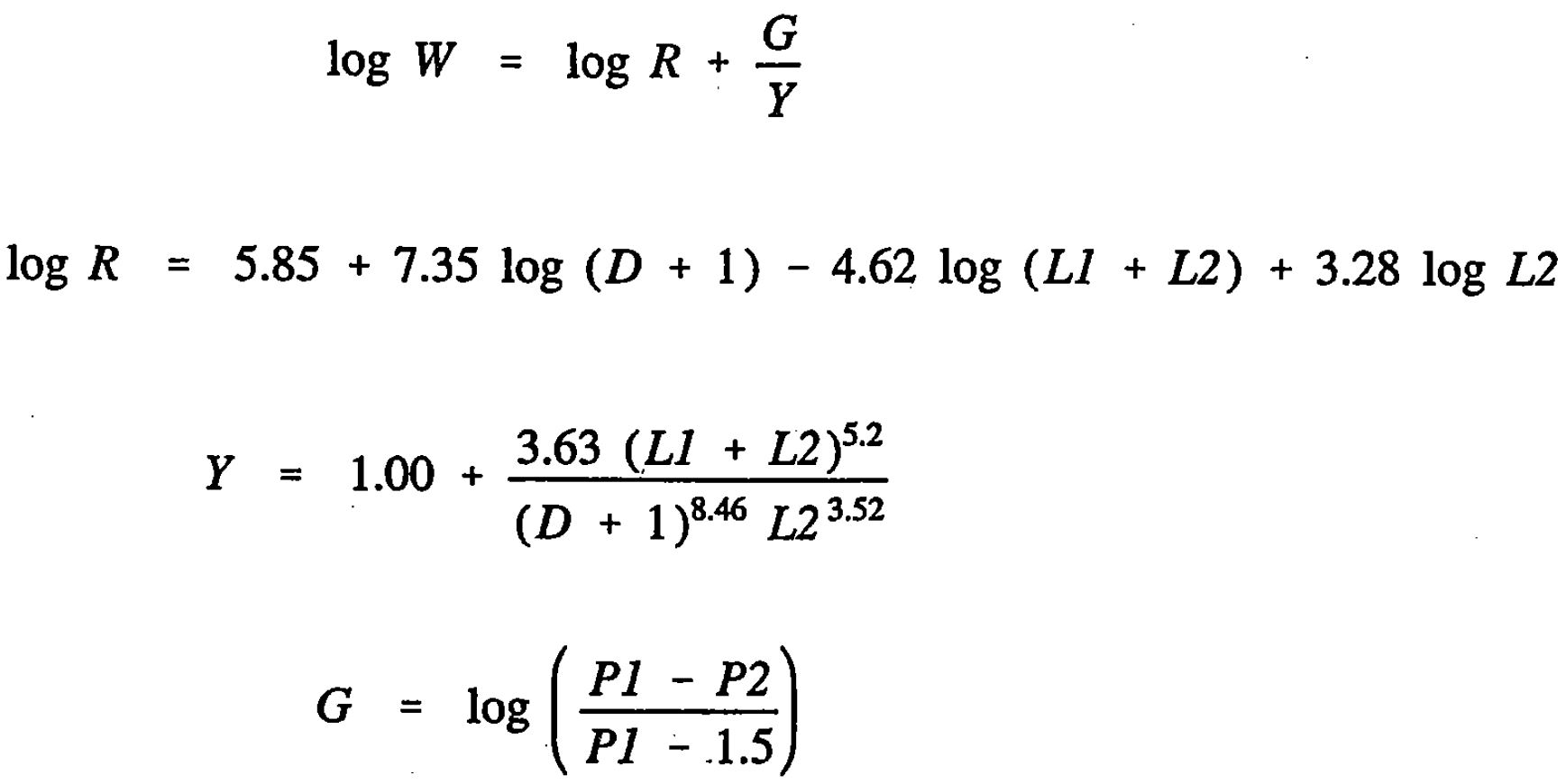

This factor is determined using the below equations where D is the concrete slab thickness, L1 is the axle load, L2 is the axle code (either 1 for single axle or 2 for tandem axles), P1 is the initial serviceability index, P2 is the terminal serviceability index.

Mean 28 Day, Third Point Loading Flexural Strength (S’c)

This is the mean flexural strength or modulus of rupture of the concrete after 28 days as determined using the third point flexural strength test method.

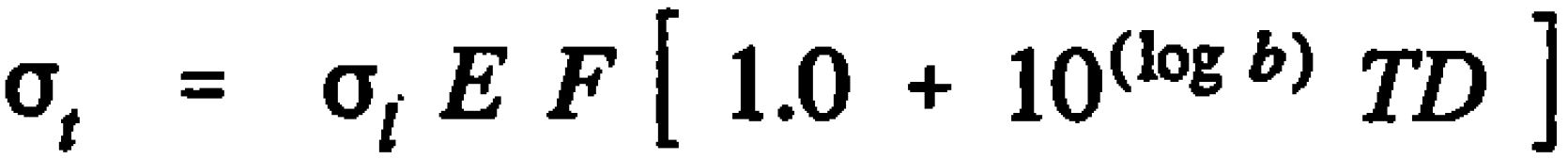

Mid-Slab Tensile Stress – Using AASHTO constants (σt) and 1998 Supplement Inputs (σ’t)

This is the tensile stress developed in the centre of the slab due to loading and temperature. This must be calculated for both the AASHTO Road Test constants and using the 1998 rigid pavement design supplement constants. This can be calculated using the below equation;

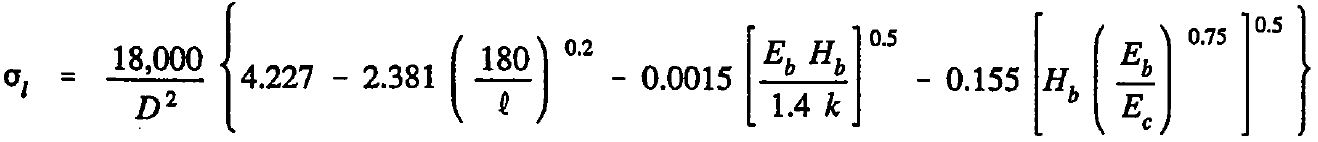

Mid-Slab Tensile Stress Due to Load Only (σl)

This is the mid-slab tensile stresses derived only by the effects of loading. This can be calculated using the below equation where Ec is the concrete slabs modulus of elasticity, Eb is the road foundation modulus of elasticity, Hb is the road foundation thickness, k is the effective elastic modulus of the subgrade.

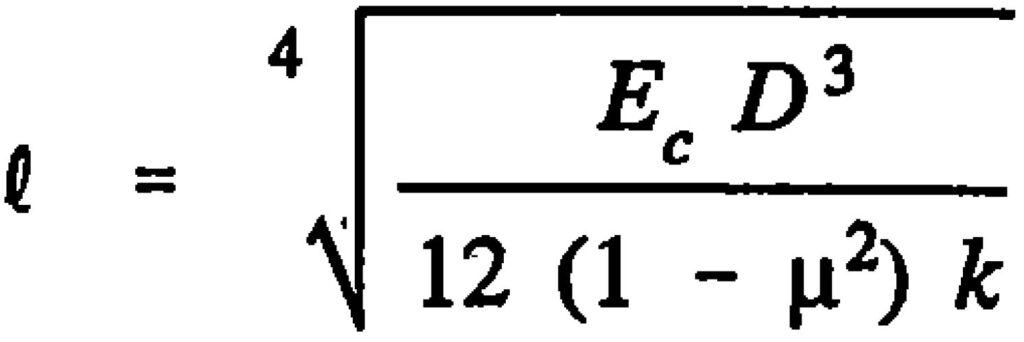

Radius of Relative Stiffness (l)

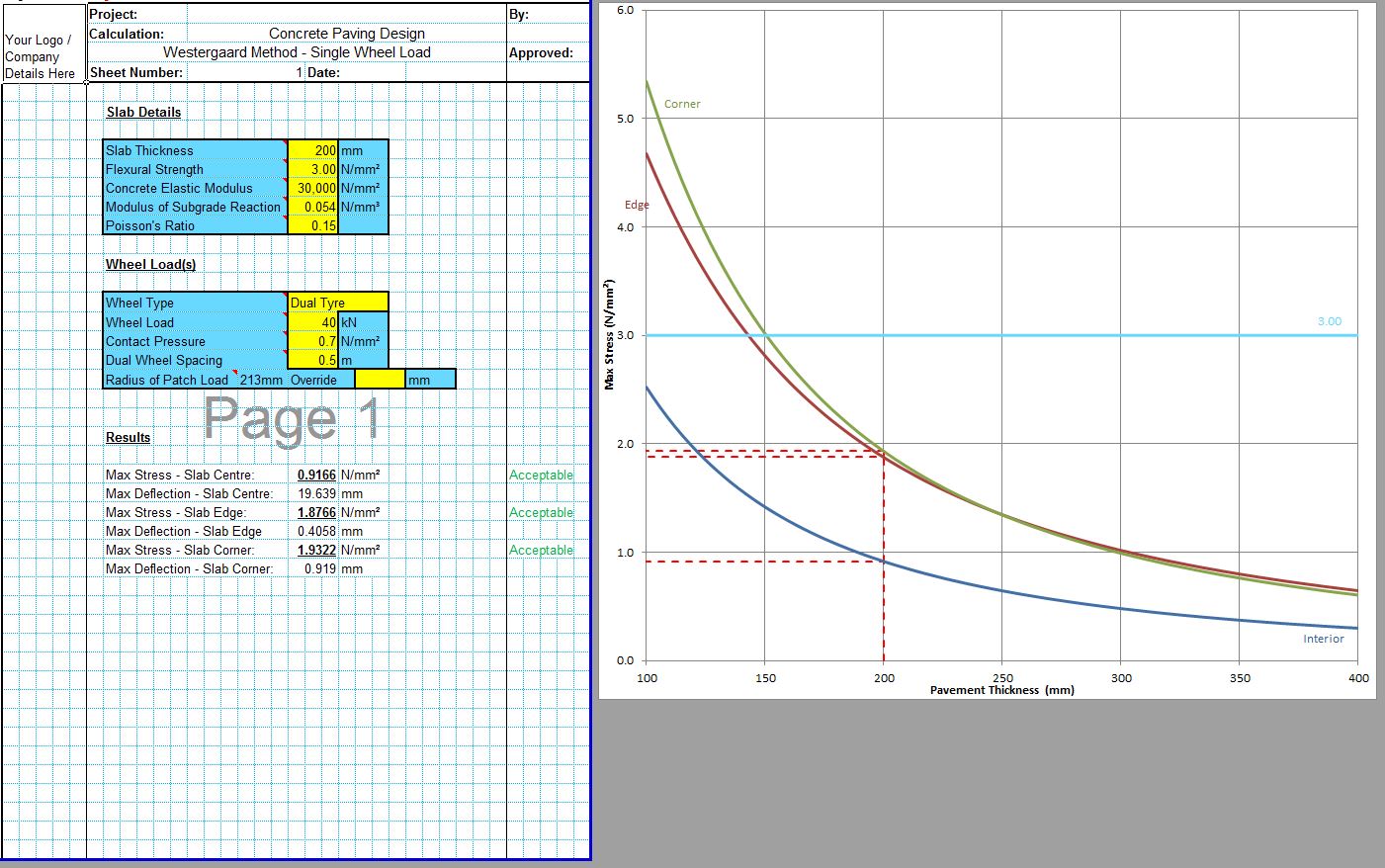

This is a measure of the relative stiffnesses of the slab and the road foundation. This is calculated in the same way as for the Westergaard Method, the equation is reproduced below where μ is Poisson’s Ratio for concrete, typically taken as 0.15 or 0.2.

Edge Support Adjustment Factor (E)

This describes the level of support which can be expected from the road foundation beneath the slab edges. This is typically taken as 1.0 for standard 3.66m wide concrete road lanes, 0.94 where a tied concrete shoulder is included and 0.92 for a 0.6m widened slab.

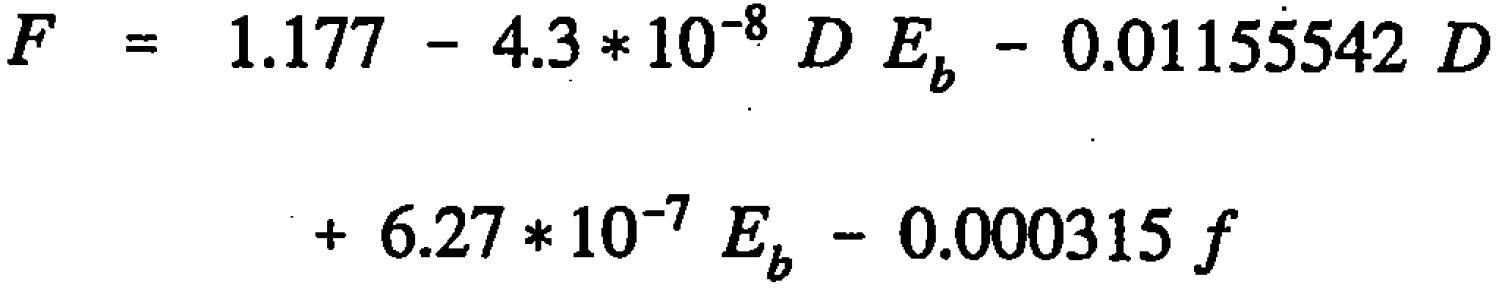

Ratio Between Slab Stress at Full Friction and at Given Friction Coefficient (F)

This factor describes the difference in the slab stress at an assumed full friction between the slab and the foundation and slab stress at the corrected friction coefficient. This is calculated using the below equation where f is the friction coefficient as shown for in the below table for different road foundation materials.

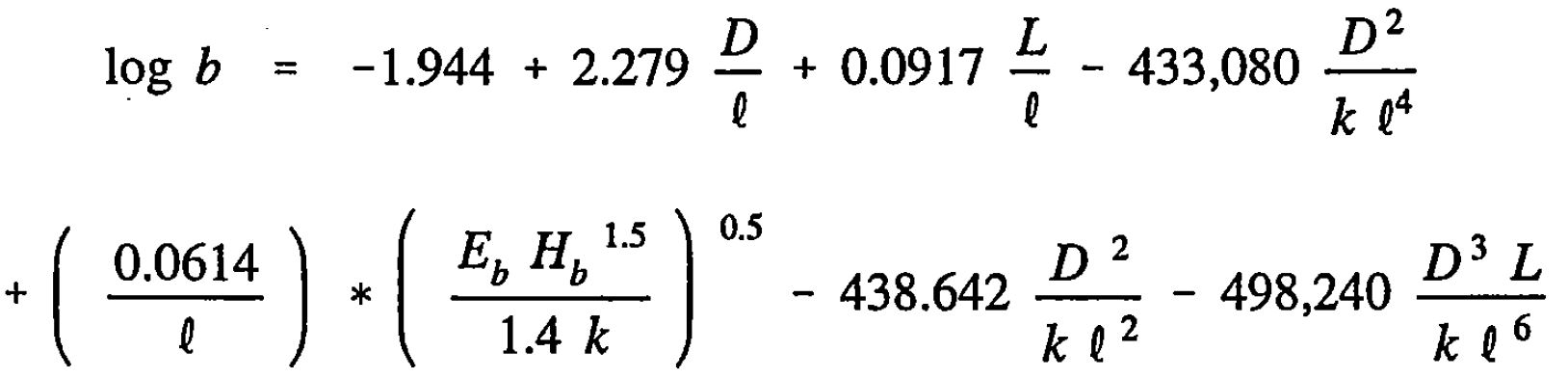

Log b

This can be calculated using the below equation where L is the joint spacing;

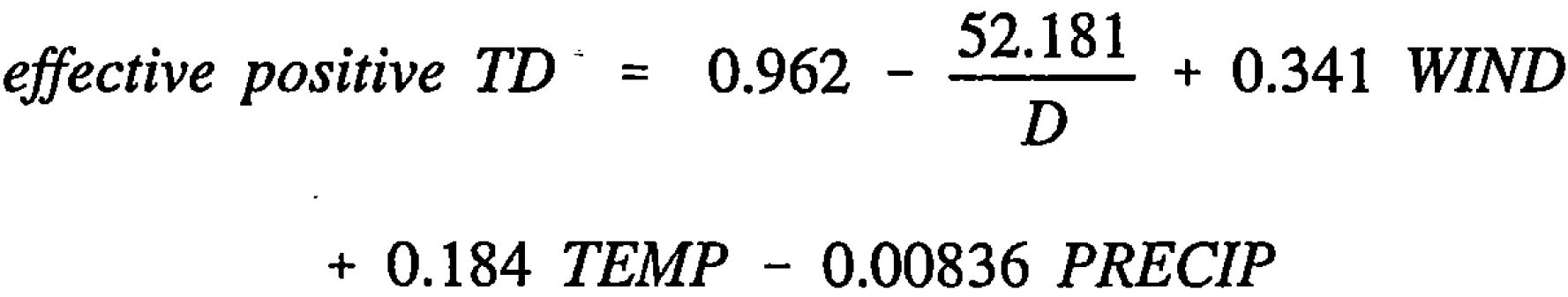

Effective Positive Temperature Differential from Top to Bottom of Slab (TD)

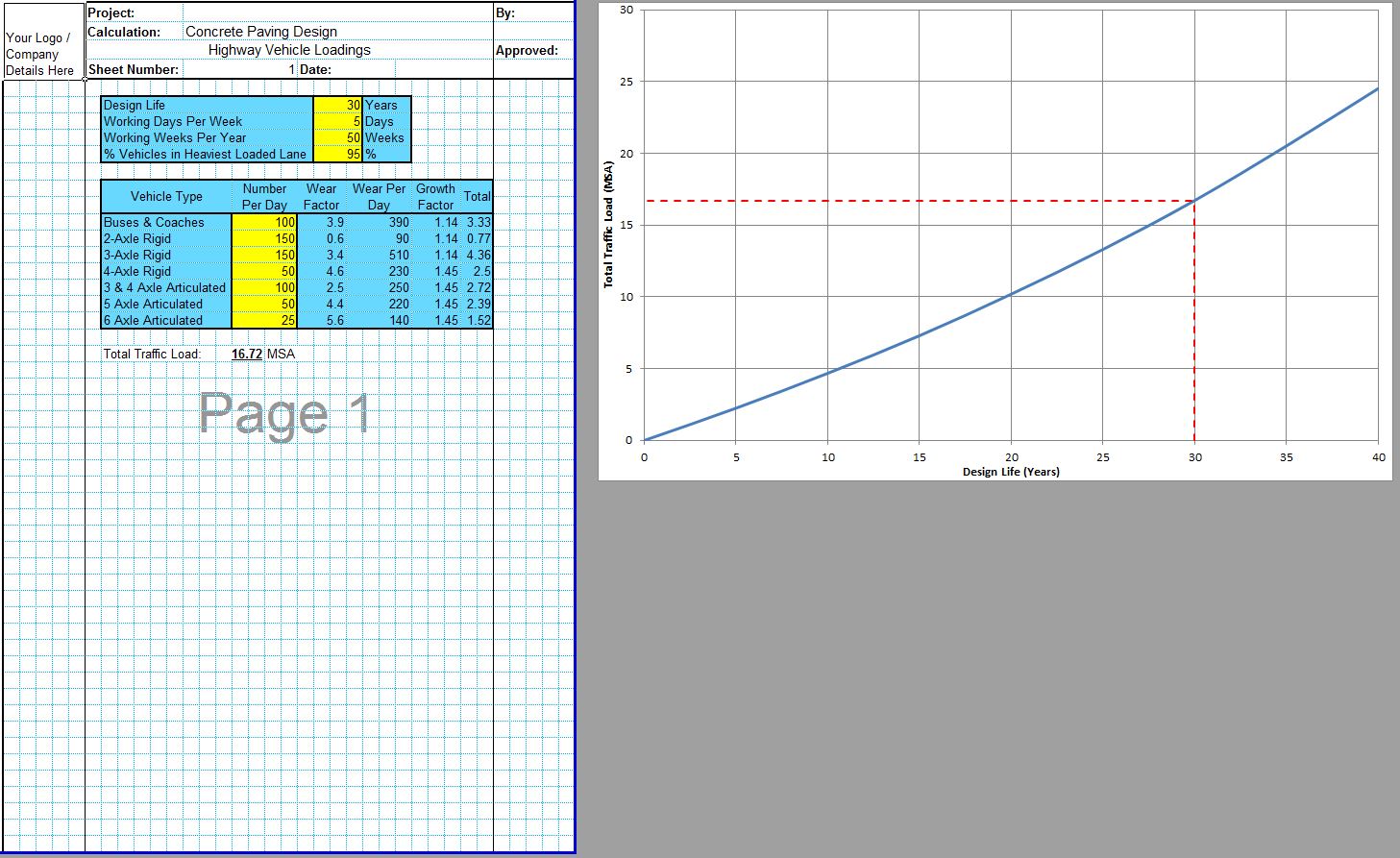

This can be determined from the following equation where WIND is the mean annual wind speed, TEMP is the mean annual temperature and PRECIP is the mean annual precipitation for the slab location. The CivilWeb AASHTO Rigid Pavement Design Spreadsheet includes typical climate info for more than 130 major US cities and regions. These climate inputs can also be input directly by the designer for use in other parts of the US or for any locations outside of the US.

Other Pavement Types

The AASHTO method of rigid pavement design was developed from performance data of jointed plain concrete pavements (JPCP). The joint spacing was the focus of the alterations made to the original AASHTO 1993 rigid pavement design equations and for this reason the AASHTO 1998 rigid pavement design Supplement is best suited to the design of JPCPs.

The equations can however be adjusted to cater for jointed reinforced concrete pavements (JRCP) and for continuously reinforced concrete pavements (CRCP). To do this hypothetical joint spacings can be input to adjust the equations to give a suitable result for pavement thickness.

JRCPs are designed with significant reinforcing steel in order to hold the cracks together closely enough to maintain load transfer through aggregate interlock and to prevent ingress of water and prevent the slab from deteriorating. For JRCPs the actual joint spacing should be used up to a maximum of 9m.

CRCPs use continuous steel reinforcement are designed to crack at very close spacing while the steel reinforcement holds the slab together. For CRCPs a hypothetical joint spacing of 4.6m can be used.

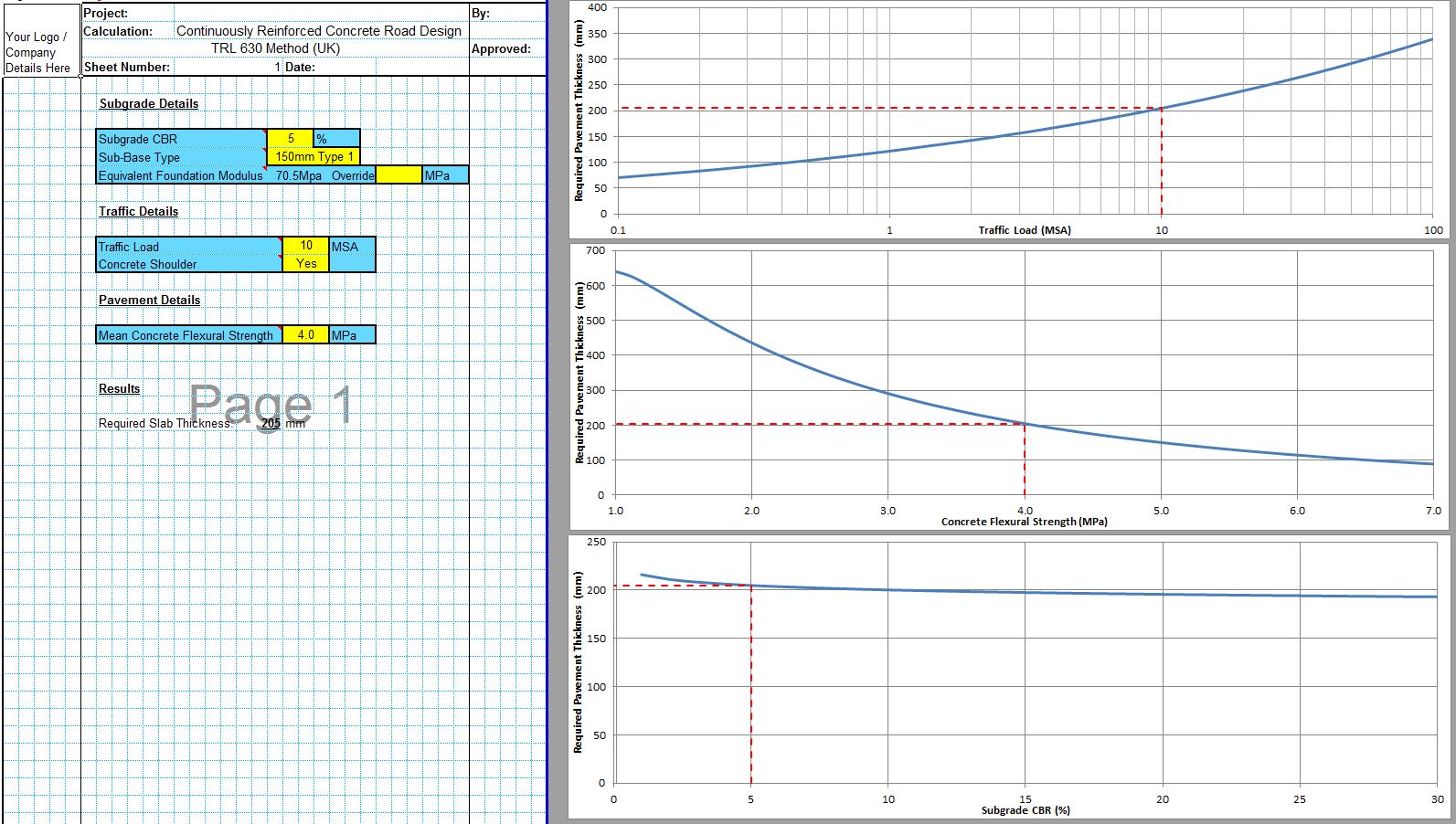

AASHTO Rigid Pavement Design Spreadsheet

Get the full license version now for only £10.

This advanced rigid pavement calculator includes 4 design modules for only £10;

- AASHTO 1986 Rigid Pavement Design Calculator

- AASHTO 1998 Rigid Pavement Design Calculator (Including US Climate Data)

- AASHTO 1998 Rigid Pavement Design Calculator (Any Worldwide Location)

- AASHTO 1998 Rigid Pavement Design Faulting Check

- Free comprehensive Ultimate User Guide. This includes detailed information and typical values for all the required inputs and an explanation of the design standards and principles used in the spreadsheet.

All purchases are covered by our full money back guarantee.

Or why not get 11 rigid pavement design spreadsheets for only £20 with our Full Rigid Pavement Design Suite?

Or bundle with our Flexible Road Design Spreadsheet suite to get our ultimate Pavement Design Excel Spreadsheet Suite including a total of 70 road and pavement design spreadsheets for only £30.

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.