The design of rigid pavements by the Westergaard method is still commonly used today for rigid pavements loaded by non-highway vehicles. The Westergaard method for rigid pavement design involves a calculation of the stresses acting in the pavement under the wheel load. This stress is then compared to the strength of the pavement slab to determine whether the slab is sufficiently strong to accommodate the proposed loadings.

The Westergaard analysis of the rigid pavement stress and strength is often combined with a separate fatigue analysis model to determine how many repetitions of this load the pavement will be able to withstand.

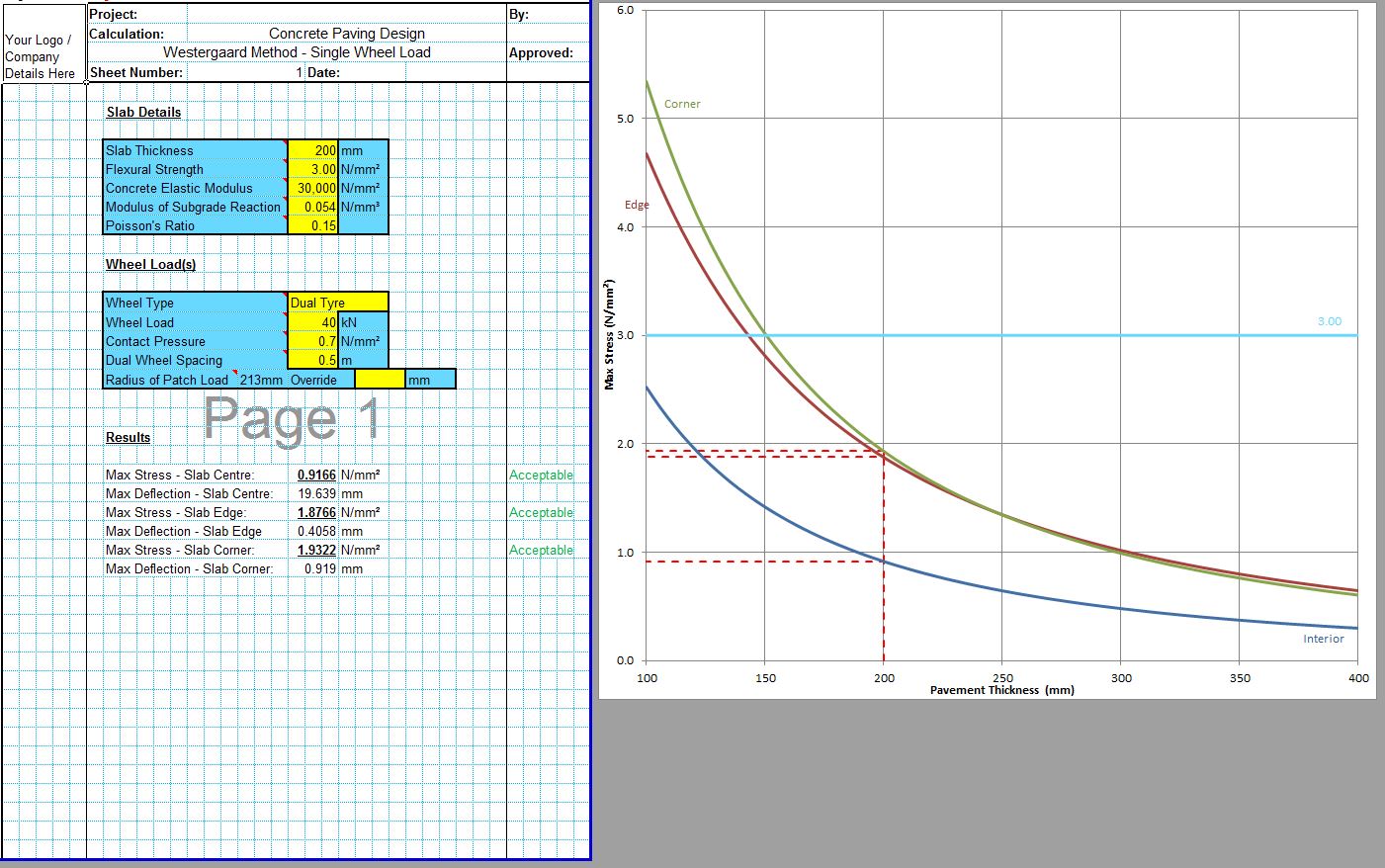

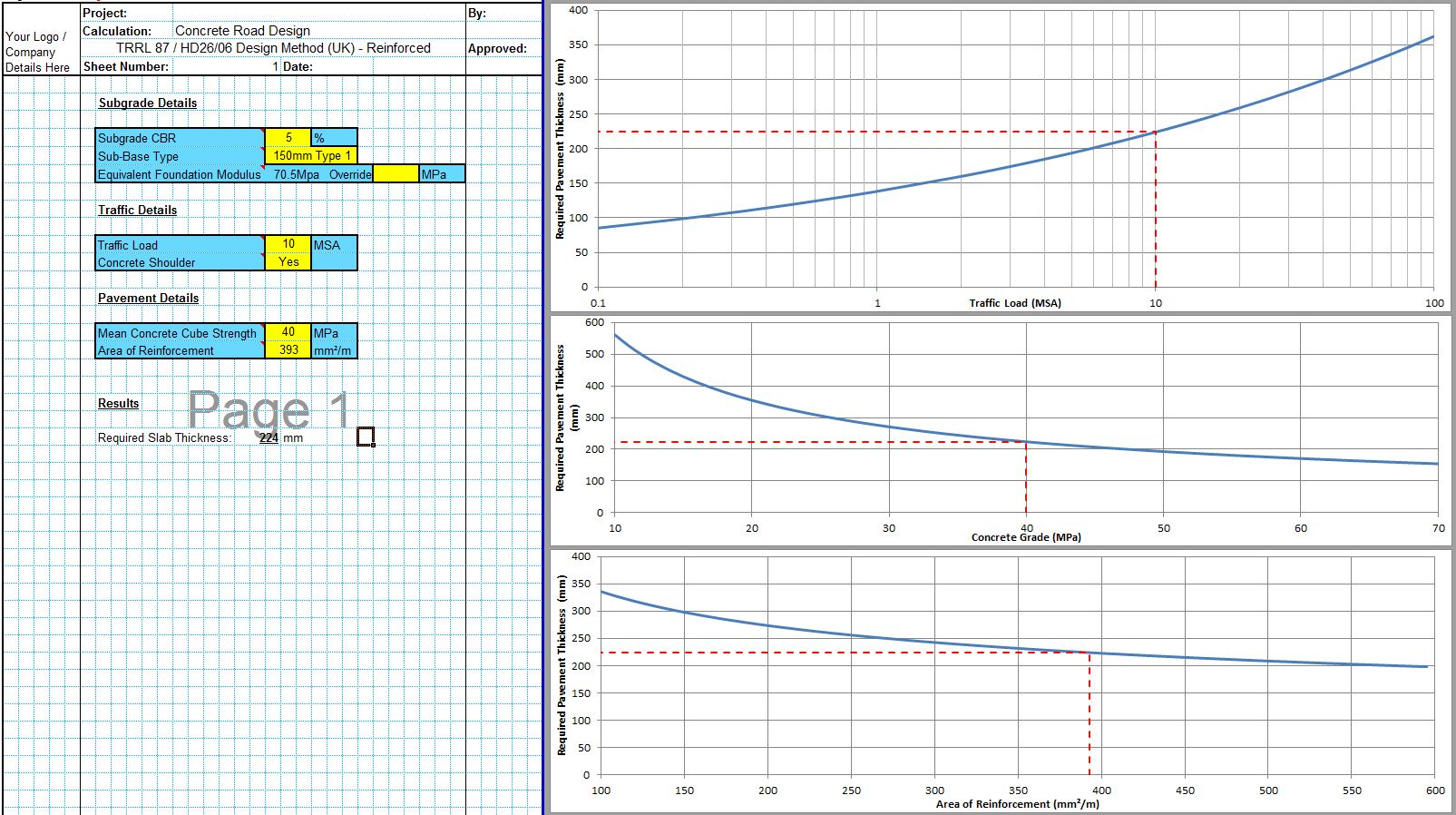

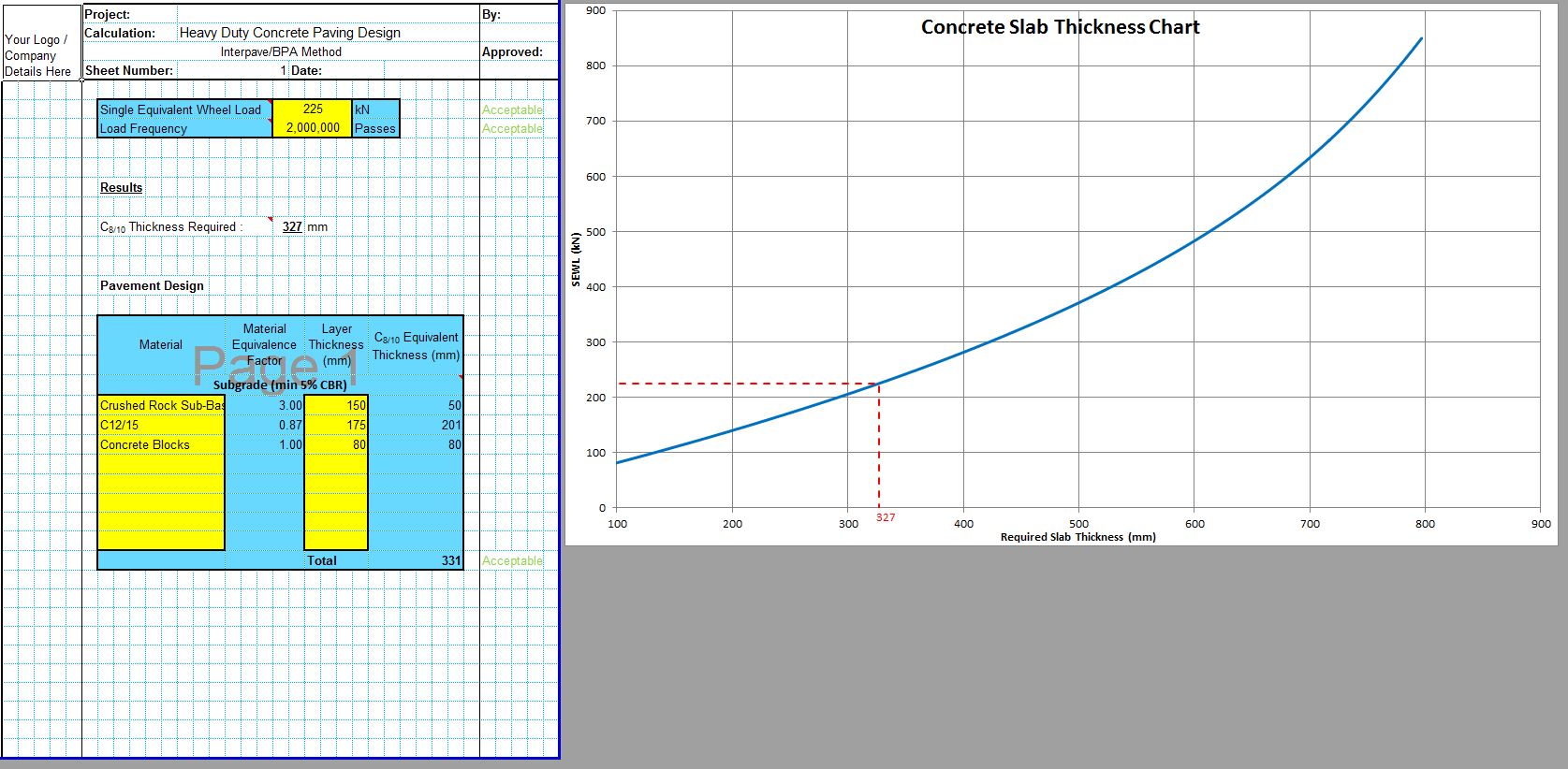

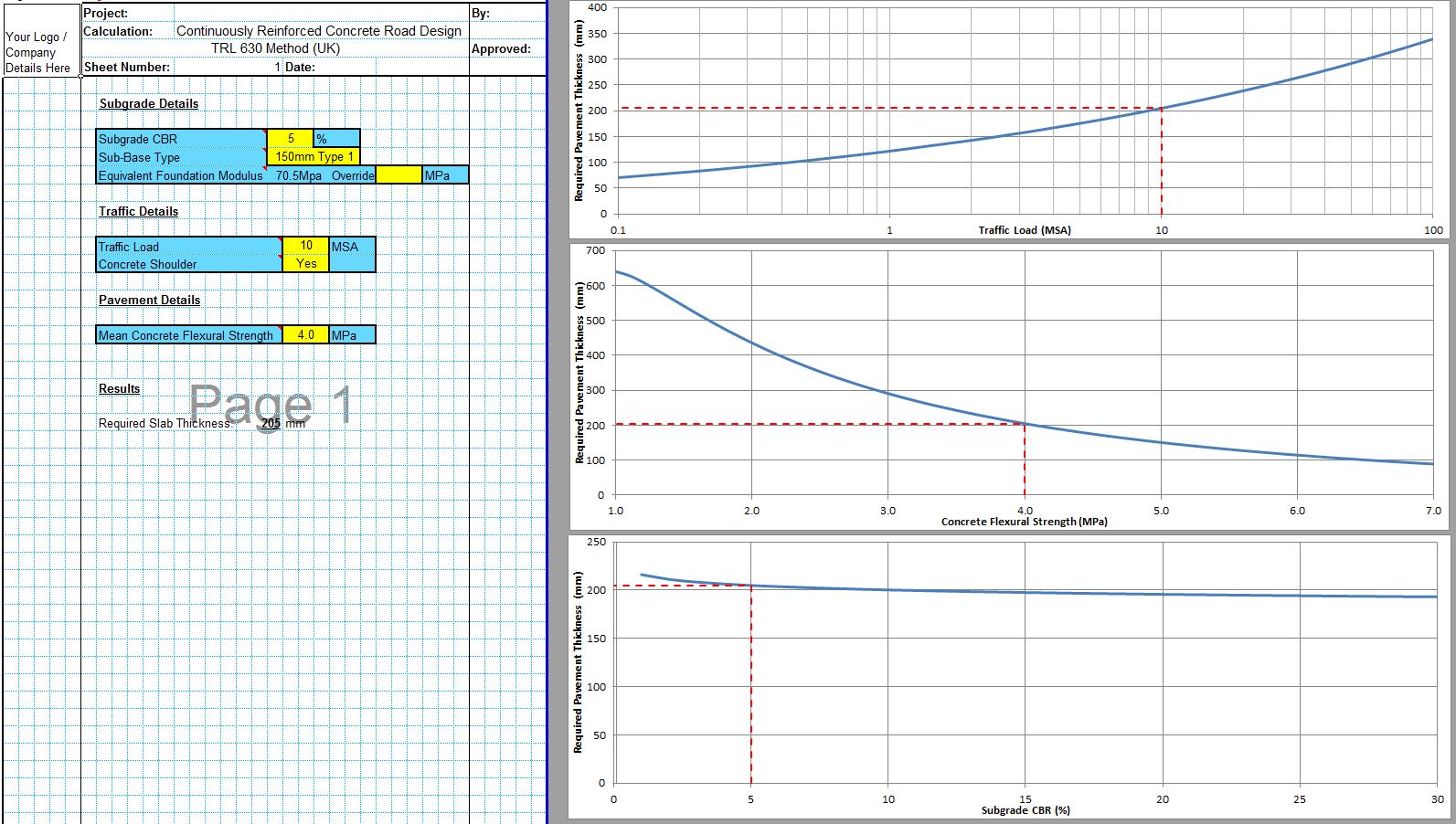

The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet completes the required calculations for a full Westergaard analysis of the rigid pavement design. The spreadsheet allows the designer to complete a full Westergaard analysis of the rigid pavement in seconds with only a handful of simple inputs. The spreadsheet even presents a design graph showing exactly where the design can be optimised.

The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet can be purchased further down this page for only £10. Alternatively the Westergaard analysis spreadsheet is included in the CivilWeb Rigid Pavement Design Suite which includes 11 different pavement design methods along with a number of other useful design tools including concrete flexural strength calculators. Follow the above link for full details.

Design of Rigid Pavements by Westergaard Method

The design of rigid pavements by Westergaard method was the earliest attempt at an analytical solution to the problem of concrete pavements supported by the ground being loaded by wheeled vehicles. The Westergaard analysis of rigid pavements for calculating the stresses under loading were developed in the 1920s and 1930s and they still form the basis of many modern design methods.

The Westergaard analysis equations can be used to calculate the stresses produced in a rigid pavement under loading from a wheeled vehicle. There are a number of simplifications and limitations inherent in this method as discussed below.

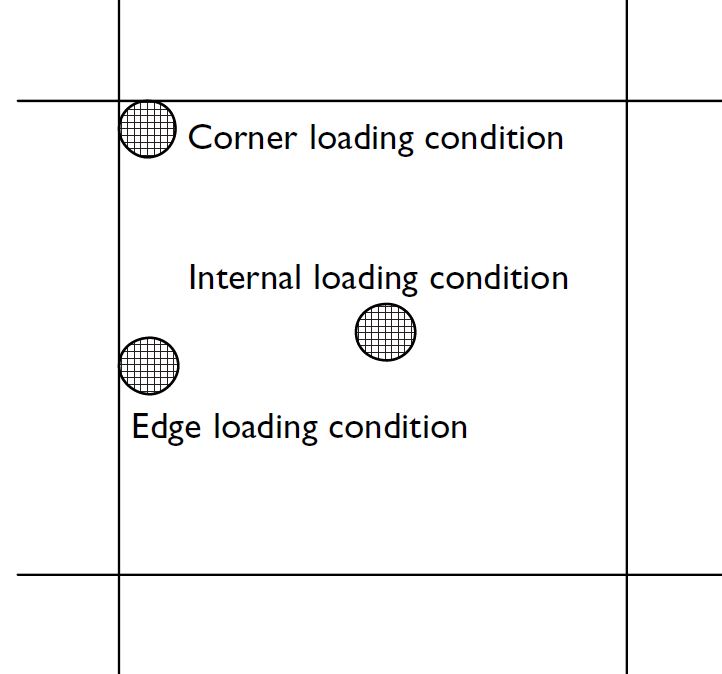

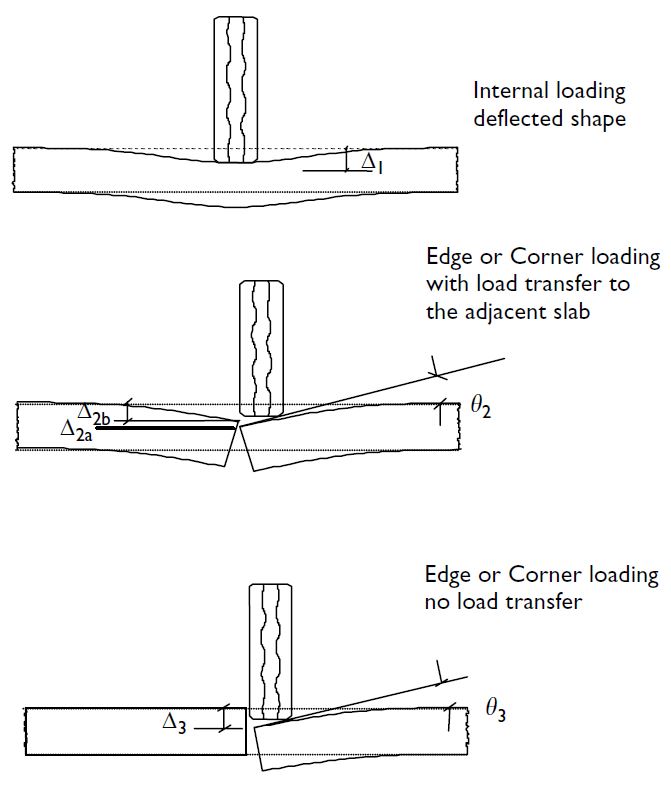

The design of rigid pavements by the Westergaard method can be used to analyse three different loading conditions, as shown in the below diagram.

Radius of Relative Stiffness

The Westergaard analysis of rigid pavements includes a calculation of the rigid pavements radius of relative stiffness. This term was derived by Westergaard himself as a way to describe the relative stiffness of the rigid pavement and the subgrade which has an effect on the stresses produced in the rigid pavement under loading. Further information is included in our Radius of Relative Stiffness post.

Westergaard Analysis of Rigid Pavements - Interior Slab Loading Condition

The interior slab loading condition was the first of the Westergaard rigid pavement analysis equations to be derived. This calculates the maximum stress in the slab under loading from a circular patch load in the interior of the slab. Note that the load does not need to occur exactly in the centre, but it must be far enough away from the edges that they do not influence the stress level in the slab.

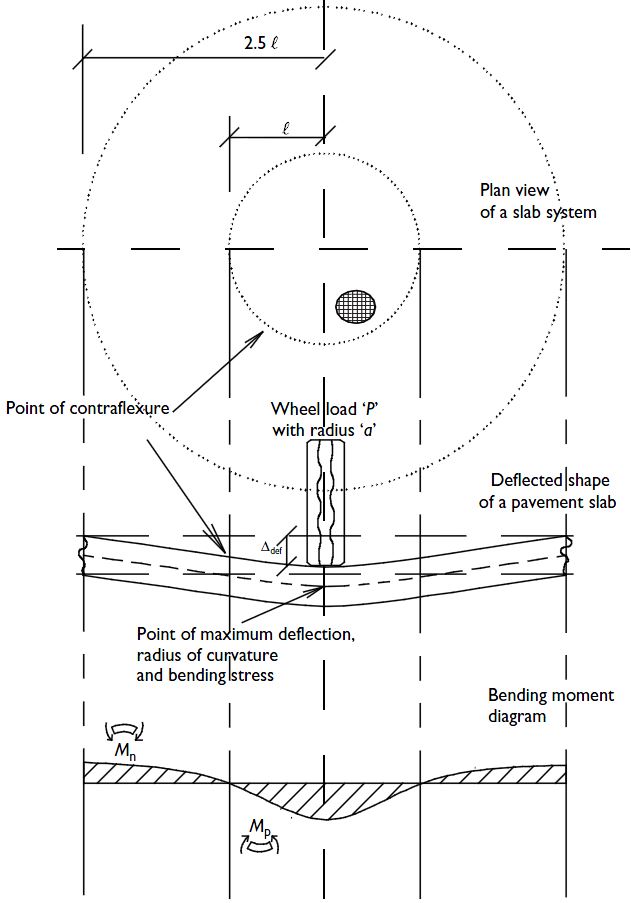

The Westergaard analysis interior loading condition leads to a slab deflection as illustrated in the below diagram. The point of contraflexure is equal to the radius of relative stiffness and the maximum tensile stresses occur at the bottom of the slab directly beneath the load. The maximum tensile stress at the top of the slab occurs at a distance of around 2.5 times the radius of relative stiffness from the load.

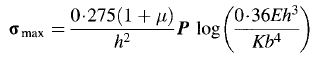

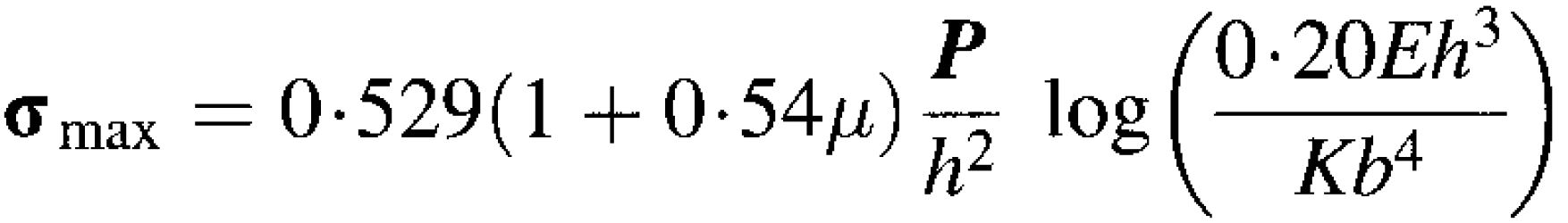

The Westergaard method equation for maximum stress (σmax) under interior loading is presented below where μ is Poisson’s ratio, h is the thickness of the slab, P is the applied load, E is the Young’s Modulus of the slab, K is the modulus of subgrade reaction and b is the load radius;

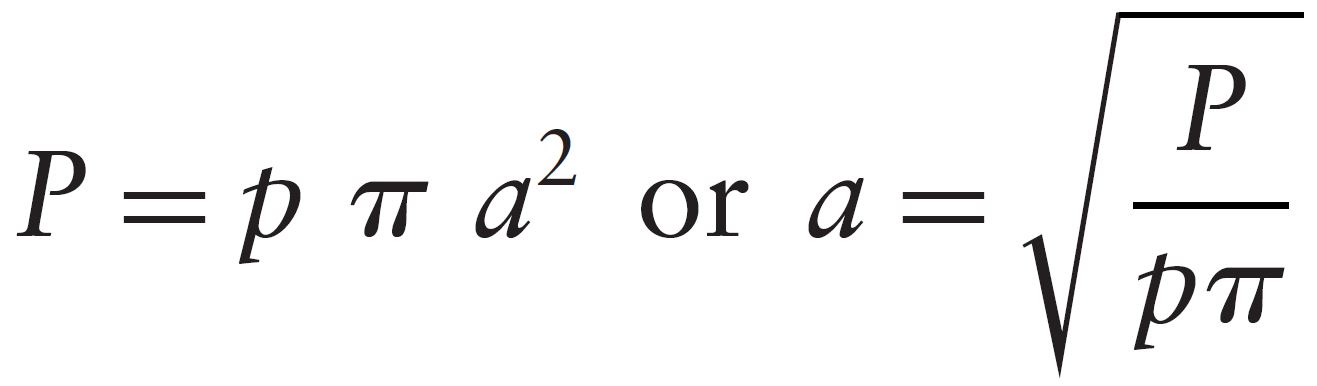

The radius of the wheel load patch can be calculated from the contact stress between the wheel and the floor (p) using the below equation;

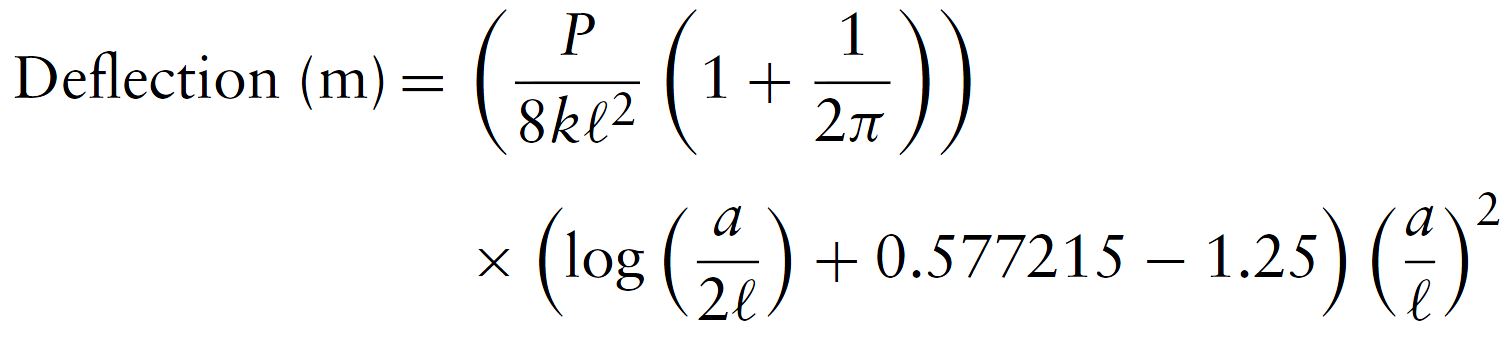

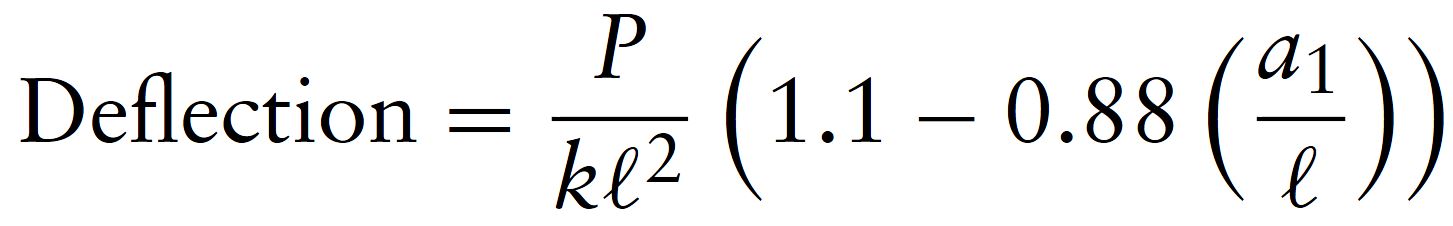

The maximum deflection can be calculated using the below equation (note that the below shows the load patch radius as a and includes radius of relative stiffness as l);

The interior stresses calculated above are rarely used directly for design because the edge and corner loading scenarios are more onerous.

Westergaard Analysis of Rigid Pavements - Edge Loading Condition

The edge loading condition in the design of rigid pavements by the Westergaard method is more frequently used as the critical condition. This condition assumes a loaded patch on the edge of the slab which would represent a wheel load crossing the edge of the slab where no load is transferred into any adjacent slabs. This design condition produces higher stresses and strains than the interior load condition.

The maximum tensile stresses for the edge loading condition in the Westergaard method for rigid pavements occur at the bottom of the slab directly beneath the applied load. The maximum tensile stress in the top of the slab occurs at a distance of around 2.5 times the radius of relative stiffness from the centre of the applied load.

The original Westergaard analysis equations for edge loading have been modified and improved many times since they were originally derived. The two most common variations used for edge loading are by Kelly and Loseberg. The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses the variation by Loseberg as this is generally more conservative and has been found to correlate well with modern finite element calculation techniques.

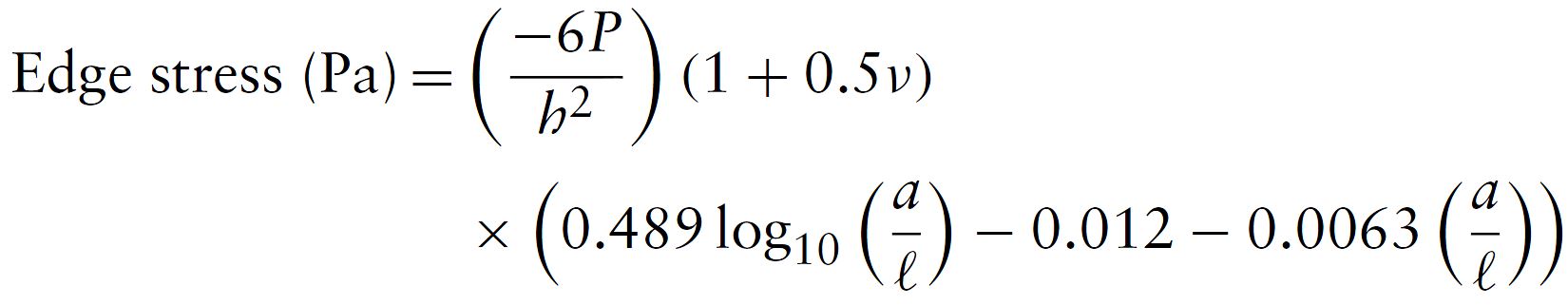

Loseberg's equation is presented below where a is the patch load radius;

Kelly’s equation for edge loading is presented below with b equal to the patch load radius;

The equation for deflection of the slab under edge loading is presented below with a equal to the patch load radius;

When using the edge loading condition in a Westergaard analysis of rigid pavements it should be noted that the design assumptions are quite conservative. It assumes the wheel load is applied to the very edge of the slab and that no load transfer between adjacent slabs is present. These are both largely unrealistic, meaning that the edge loading condition is conservative.

Westergaard Analysis of Rigid Pavements - Corner Loading Condition

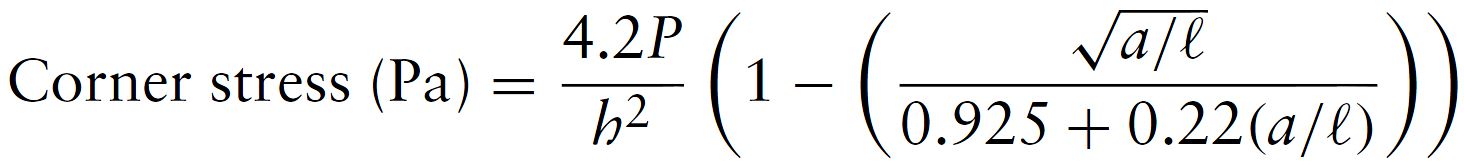

The corner load condition is generally the most onerous of the three loading conditions and for this reason it is the corner loading condition which is most commonly incorporated into other rigid pavement design methods.

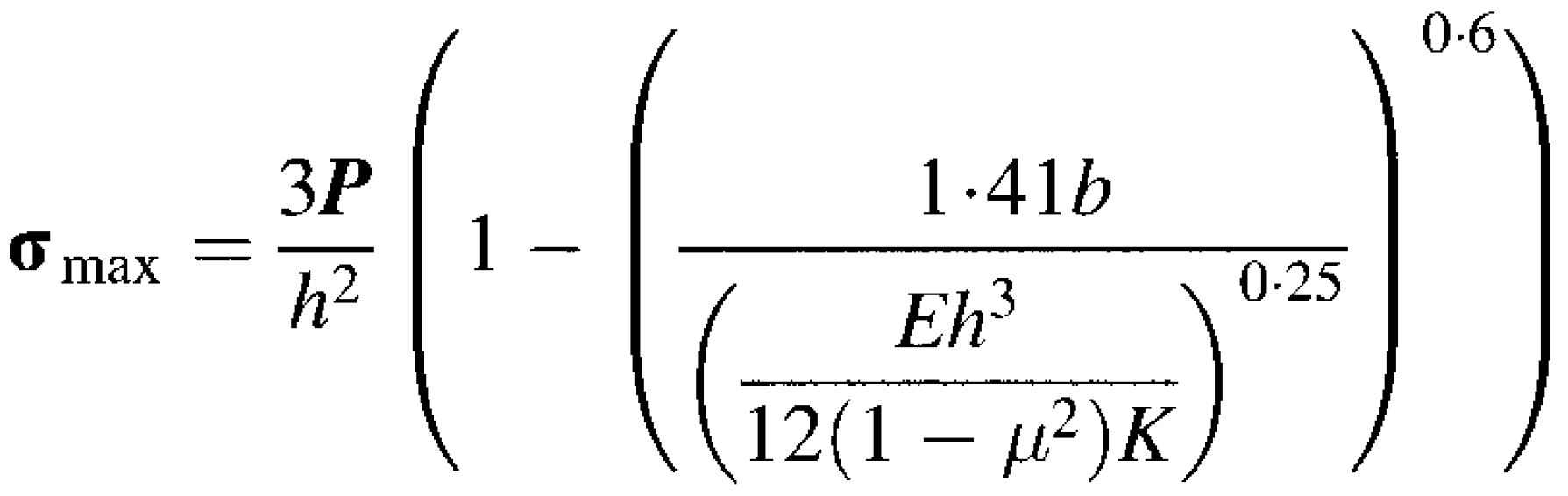

Similar to the edge loading condition, a number of variations have improved the original Westergaard analysis equation since it was published. The original Westergaard equation is presented below;

Modern finite element calculation techniques have however indicated that this equation returns results that are around 10% below the finite element results. For this reason an alternative empirical equation by Pickett based on measurements of strain in real slabs is often used in place of the original Westergaard analysis equation. Picketts equation is shown below;

The equation for deflection is presented below;

Similar to the edge loading condition, the corner loading condition is quite conservative in that it assumes the wheel loads acts directly on the corner of the slab and no load is transferred into any adjacent slabs.

General Limitations & Assumptions

In order to complete the calculations with a closed form solution the design of rigid pavements by the Westergaard method includes the following assumptions and simplifications. The designer must be satisfied that these assumptions are valid for the design conditions considered.

- The Westergaard analysis of rigid pavement design technique involves simplification of the problem of wheel loading on a slab by assuming that the contact area is circular. This forms a circular patch load with stress distributed evenly across the patch. In most cases this simplification is reasonable even though the contact area is usually closer to a rectangle than a circle. The assumption of a circular contact area leads to only a small error and is conservative.

- The concrete slab is assumed to be an uncracked laminar.

- The slab is large enough so that the interior loading condition is not affected by the slab joints. Research has shown that the Westergaard analysis equations are applicable for slabs larger than 3.5 times the radius of relative stiffness (l).

- The design of rigid pavements by the Westergaard method assume that there is no structural connection between the slab and any adjacent slabs. This is usually very conservative as there will usually be considerable load transfer between adjacent slabs. A properly designed and constructed pavement joint will usually transfer at least 70% of the load across the joint. The effects of proper load transfer across joints is illustrated in the below diagram.

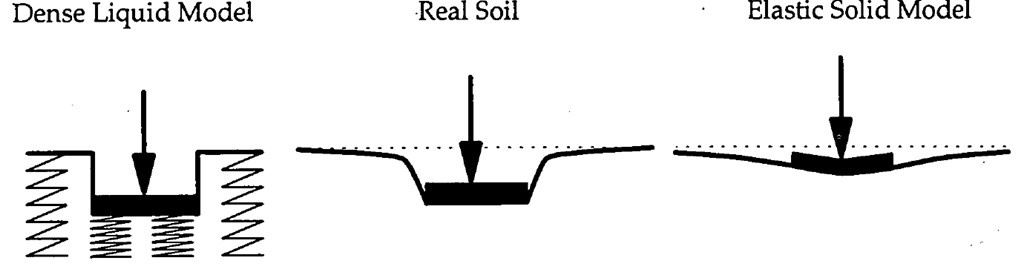

- The rigid pavement is supported on a uniform support. The soil is modelled as a series of independent springs, with the stiffness presented as the modulus of subgrade reaction. This is known as a dense liquid foundation or Winkler foundation. There are some solutions to the problem which use a solid foundation or elastic half-space. This assumes that under load the soil deflects to produce an infinite deflection basin. The two models can be compared with a typical real soil response using the below diagram.

- Real soil responses typically lie somewhere in between the dense liquid and elastic solid models as shown below. The elastic solid model is much more complex mathematically than the dense liquid model, though this is less of a concern now than it was 50 years ago. Research has shown that the liquid foundation model more accurately predicts the stresses in the slab for corner and edge loading conditions which are the most onerous and most likely to be used for design. The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses the dense liquid foundation as this is deemed suitable in most concrete slab design applications.

- The Westergaard analysis of rigid pavements model also assumes that the slab is in constant contact with the foundation. In some cases this may not be the case, for example when the foundation has deteriorated due to pumping of fines or where curling has allowed the slab to lift off the foundation completely at the corners. For this reason Pickett’s corner stress formula is often used by designers as this is based on corners which are not supported by the ground. Experimental results suggest that this more onerous condition is more accurate than Westergaard’s analysis. The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses Pickett’s corner loading formula.

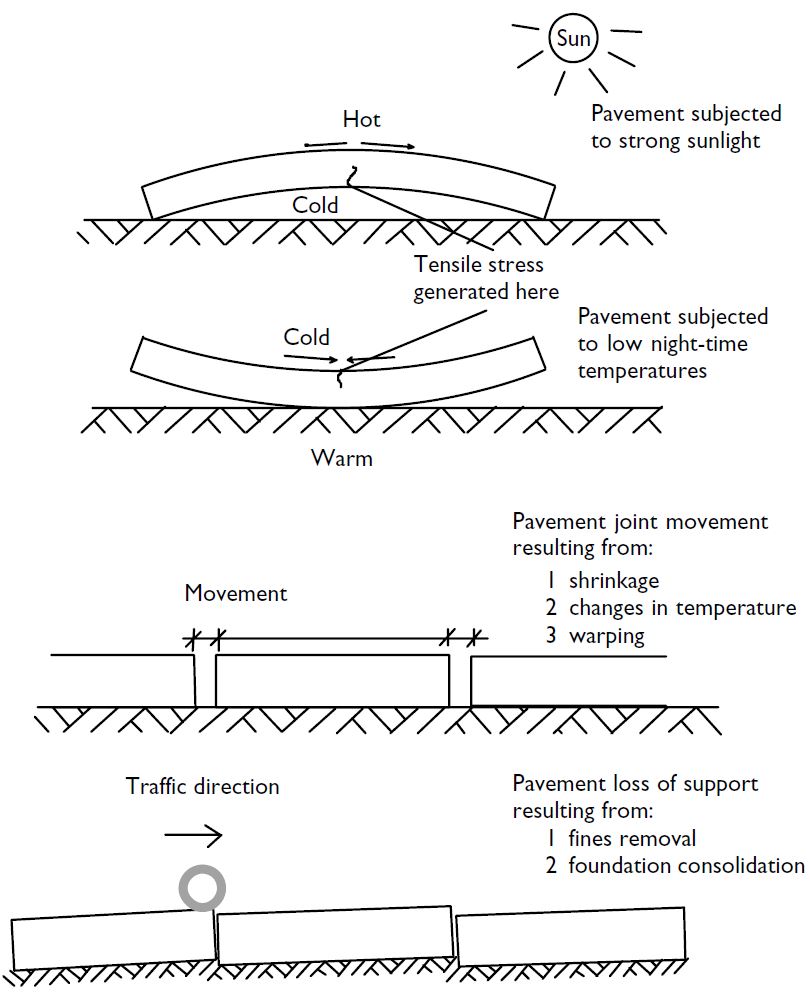

- There is no allowance in the design of rigid pavements by the Westergaard method for the stresses produced by environmental factors. Changes in temperature will warp the slab producing stresses. During the day the slab will warm producing tensile stresses in the base of the slab and during the night the slab will cool producing tensile stresses in the surface. This is particularly the case for external slabs were temperature variations will be large and will occur every 24hrs for the design life of the pavement. Temperature changes will also cause the slab to expand and contract, producing friction stresses from the underlying sub-base.

- Other environmental effects such as a loss of support from pumping and consolidation will also be significant in some cases. These effects are often neglected by designers. The additional stresses will need to be calculated and accounted for in the design along with the loading stresses. The calculation of these stresses is included elsewhere in this document.

- However when the Westergaard stresses are to be used in a fatigue equation, the environmental stresses are not usually included. This is because these stresses will occur only once per day, whereas loading stresses may occur millions of times over the slabs design life. Also a properly designed slab will include well-constructed joints at a small enough spacing to prevent significant curling stresses from developing within the slab. The effects of these environmental stresses is illustrated in the below diagram.

Dual Tyre Loads

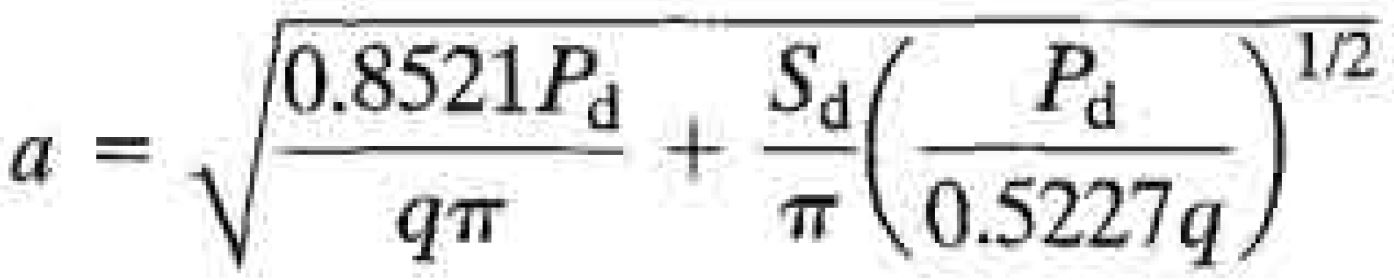

Many heavy vehicles use dual tyres to spread the loading over a wider area. In order to apply the Westergaard equations to dual tyre loads we must convert the tyre loads to an equivalent single circular area. The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses the below equation where a is the equivalent single circular patch load radius, Pd is the load on each tyre, q is the contact pressure and Sd is the spacing between the tyre centres;

Multiple Wheel Loads

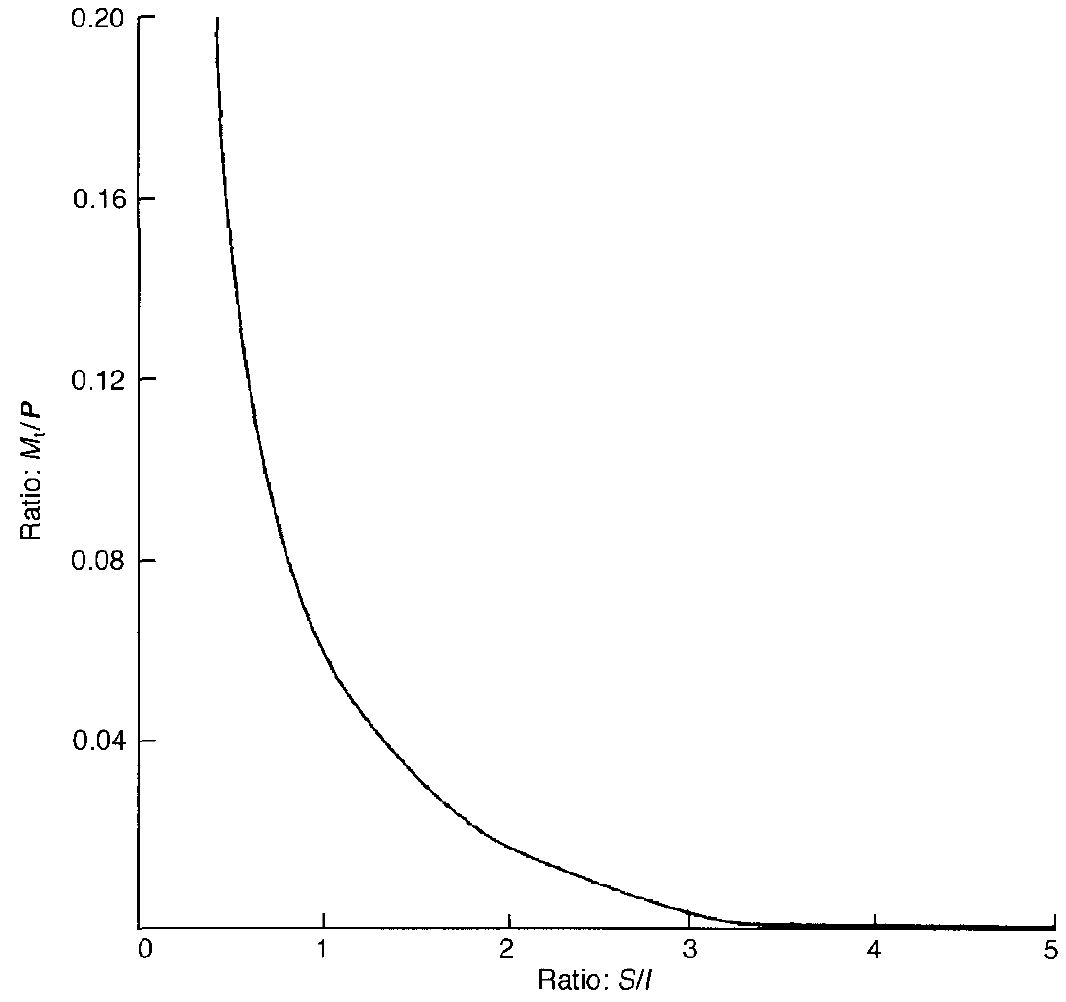

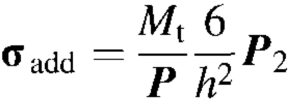

In some cases there may be additional wheels in close proximity to wheel considered which will have an effect on the maximum stress. In these cases the CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses an empirical method to estimate the increase in maximum stress beneath the main wheel. The below graph and equation can be used to estimate the additional stress where Mt is the tangential moment caused by the additional load, P is the main wheel load and P2 is the secondary load, l is the radius of relative stiffness and S is the spacing between the centre of the load patches.

Design of Rigid Pavement by Westergaard Method

The results from the Westergaard analysis will be a maximum stress in the slab for each of the three loading conditions described above. Significant engineering judgement will need to be exercised when deciding which of the loading conditions are appropriate for the design case and whether any further adjustments are required, for example to take account of some load transfer between slabs.

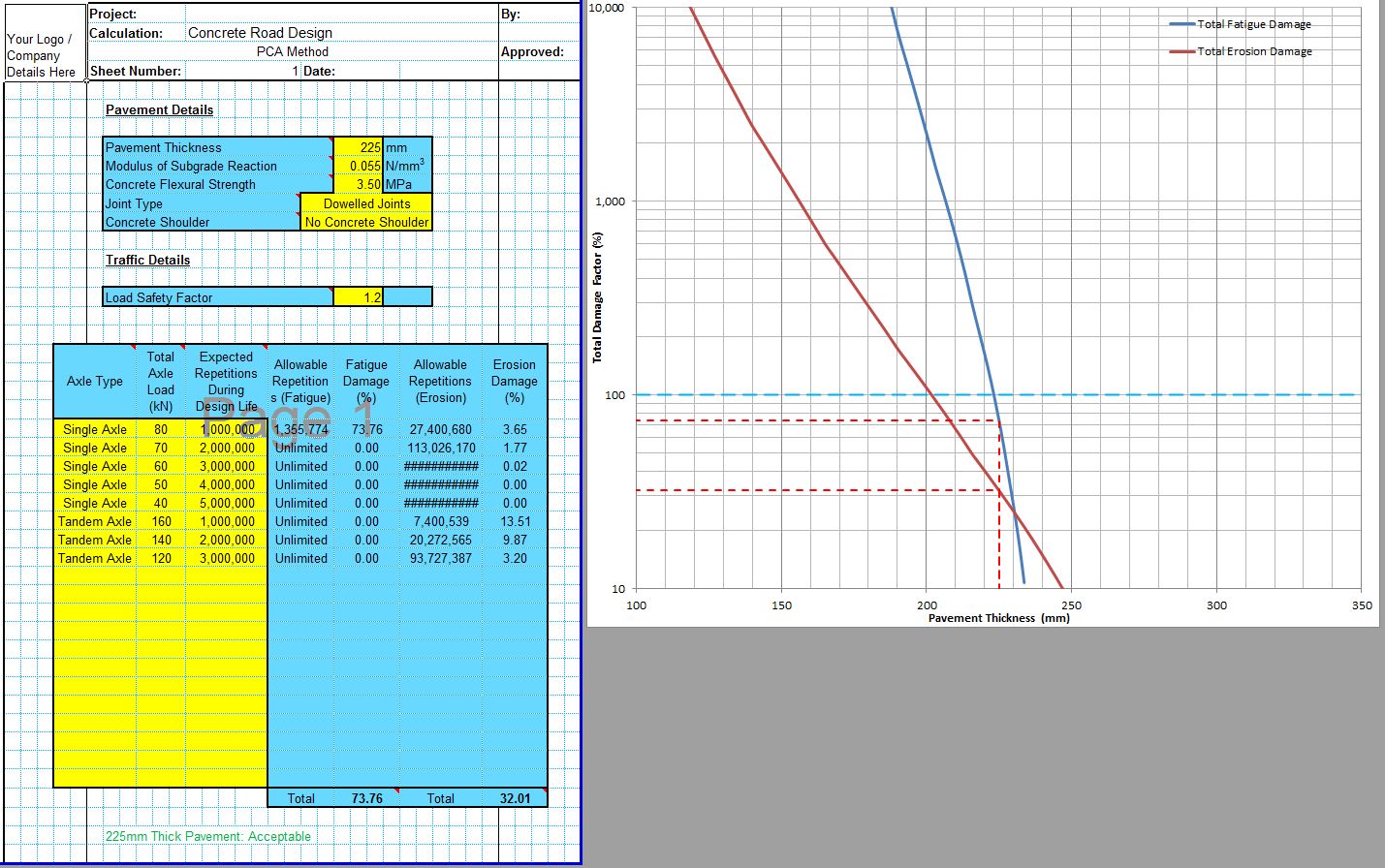

When the final stress is determined this can be compared with the characteristic flexural strength of the pavement to determine whether the concrete will fail or not under the imposed load. Pavements however seldom fail under a single load, they fail due to fatigue caused by repeated loading. Each loading cycle will cause small cracks in the concrete which slowly propagate through the concrete each time it is loaded. To determine the design life of the pavement under the design loading the results from the Westergaard analysis must be input into a suitable fatigue model. Various fatigue model calculation tools are included with the CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet which can be used to determine the design life of the pavement.

CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet

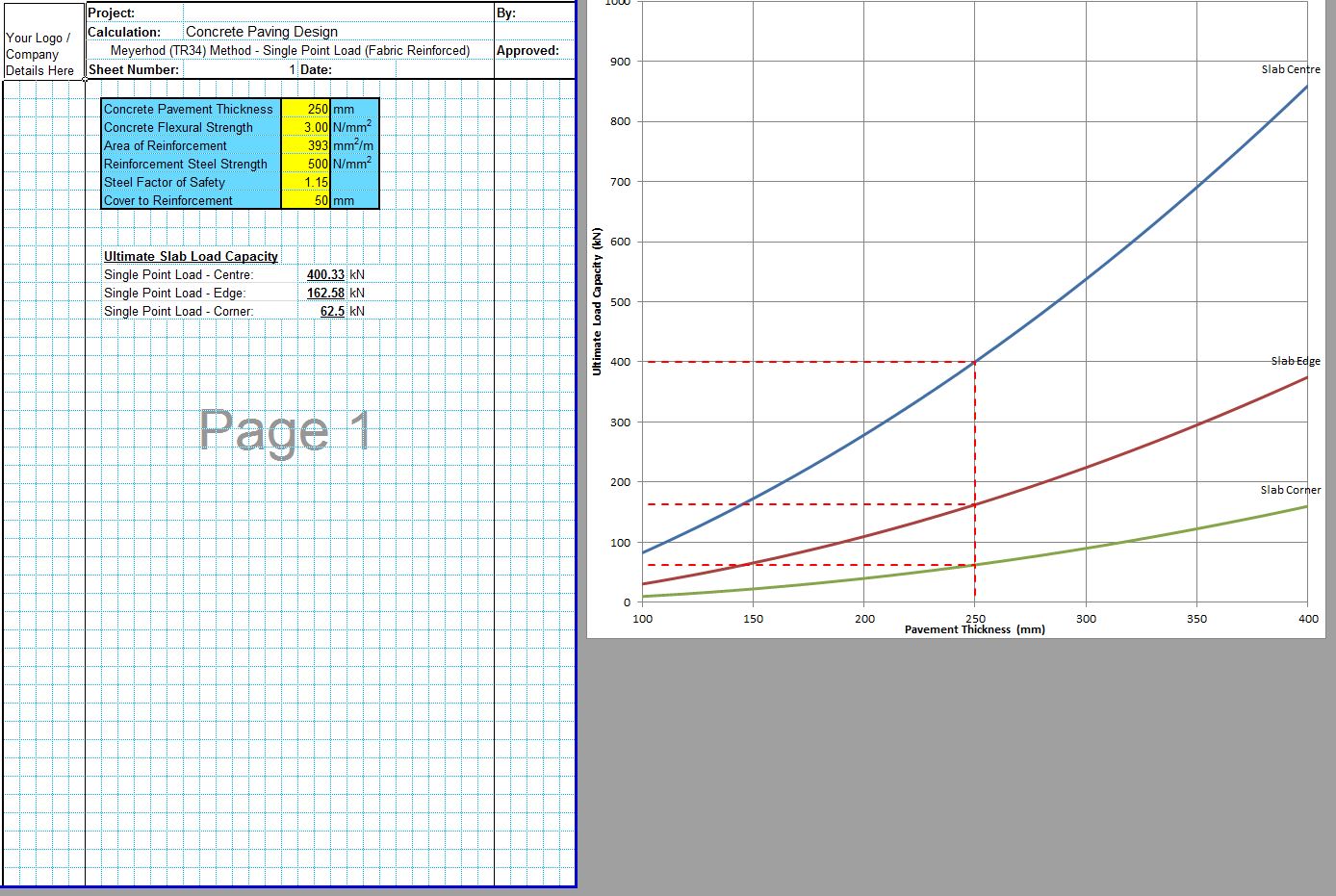

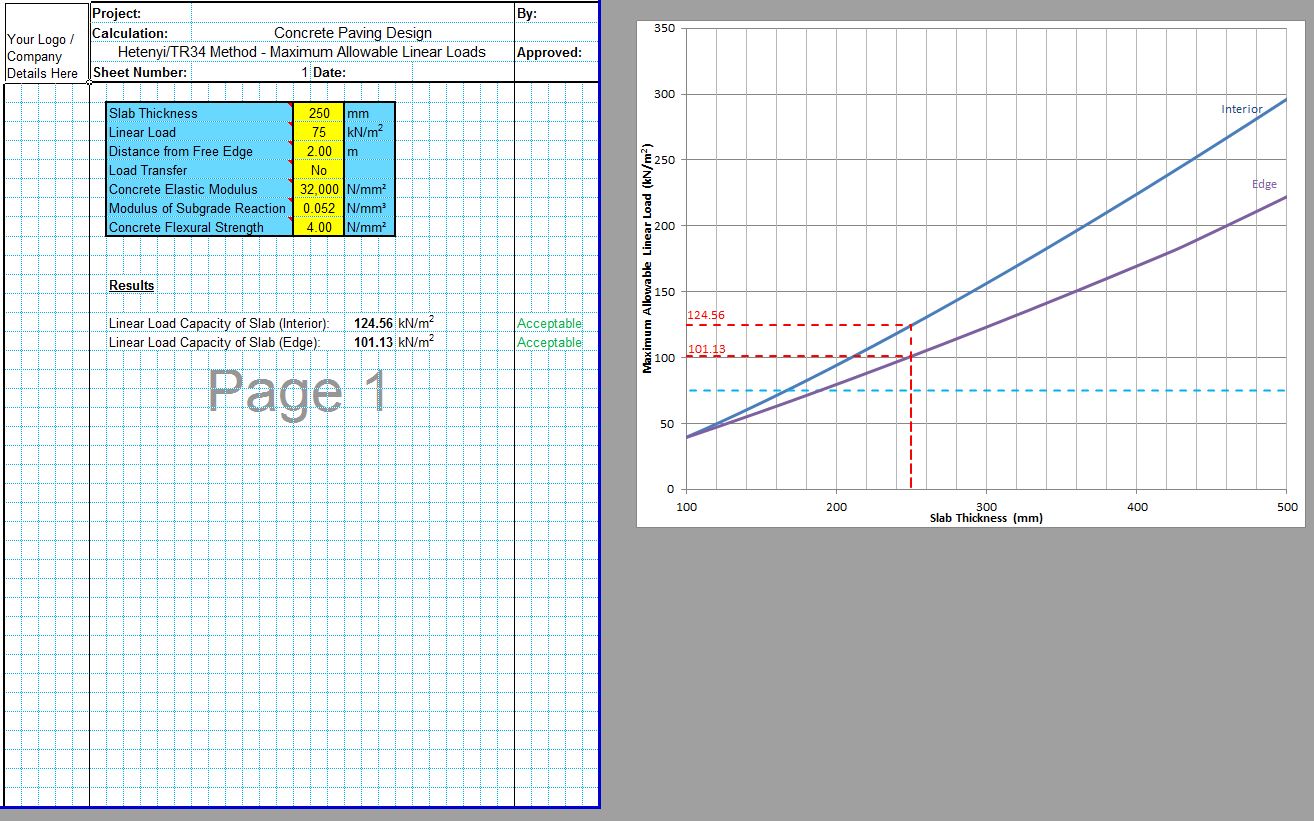

The CivilWeb Westergaard Method for Rigid Pavement Design Spreadsheet uses the Westergaard analysis techniques described above to calculate the maximum stresses induced in the pavement. The calculations are completed for three load conditions, slab centre, slab edge and slab corner. The stresses produced by each of the design conditions are then presented for the designer to choose which is critical.

This is then compared with the flexural strength of the concrete to determine whether the slab is adequate. This can be done for single or dual tyre loads. The spreadsheet then uses a fatigue model to calculate how many repetitions of the load that the slab will be able to accommodate.

Buy now for only £10

Or why not buy our full Rigid Pavement Design suite for only £20

Or buy our best value bundle, the full Pavement Design Suite including flexible and rigid pavement spreadsheets for only £30

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.