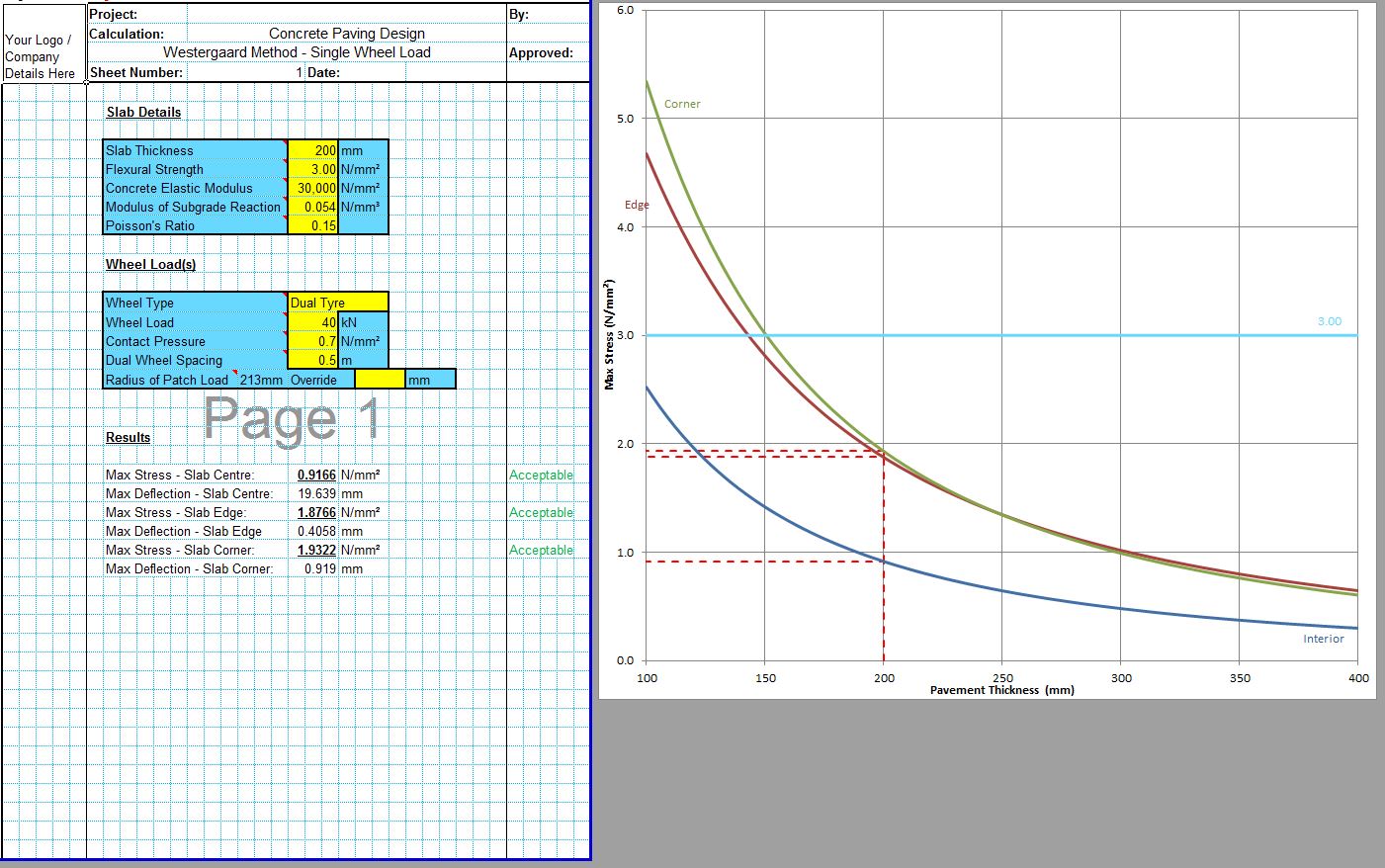

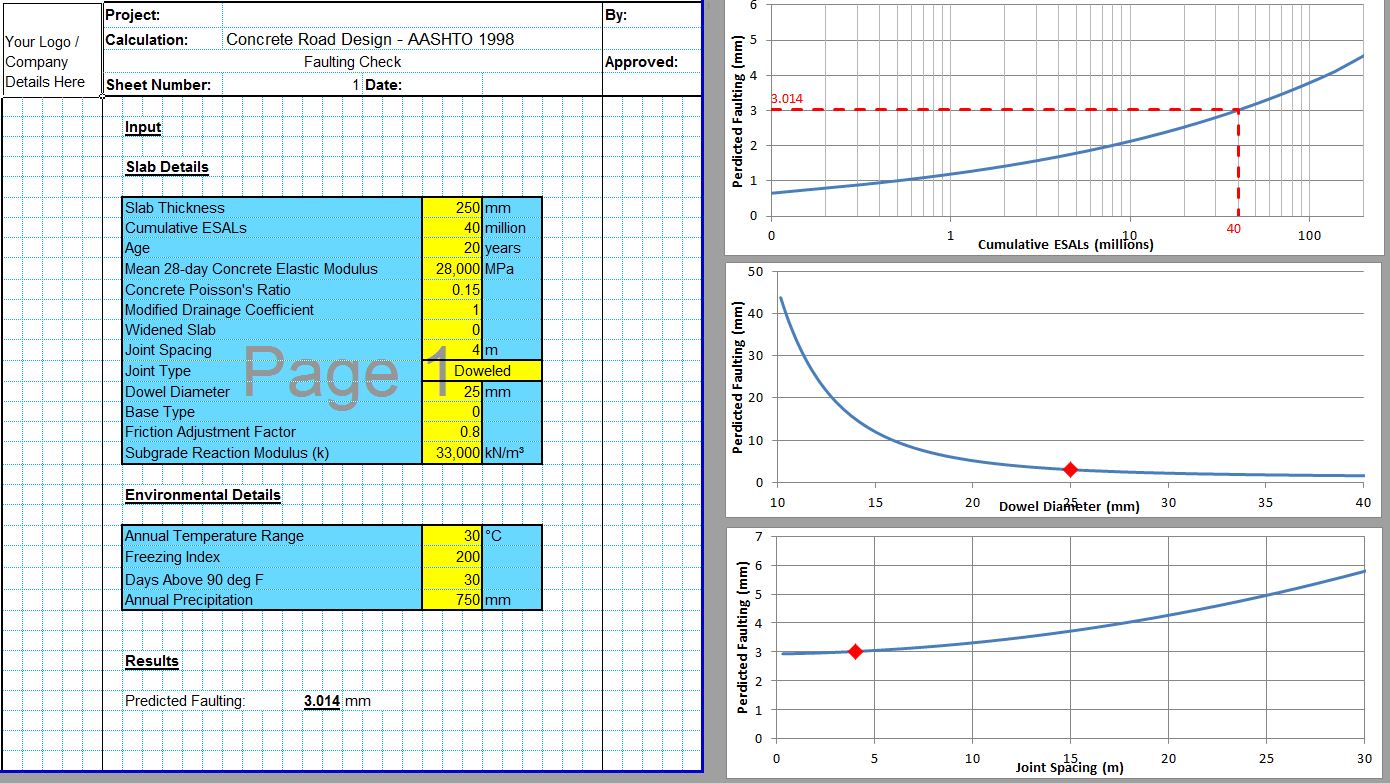

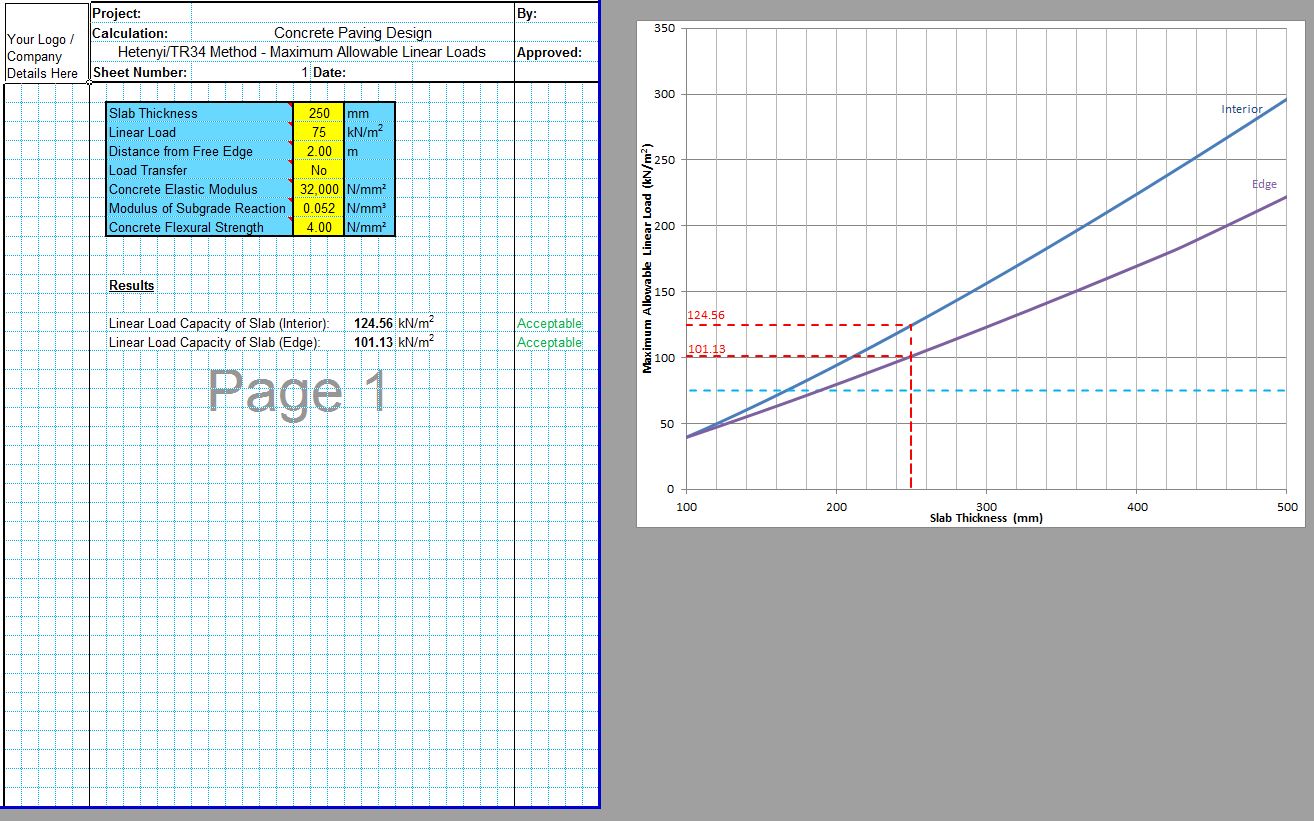

Heavy duty concrete pavement design cannot use the same empirical methods as concrete road design. This is because heavy duty concrete pavements must be designed to accommodate the loadings from heavy duty plant and equipment that are much larger than those allowed onto highways. Westergaard methods or finite element methods need to be used to analyse the stresses in the pavement and soils caused by the heavy duty loadings.

In the UK the most commonly used method of heavy duty concrete pavement design was developed by the British Ports Association using finite element modeling. This is the method used in the CivilWeb Heavy Duty Concrete Pavement Design spreadsheet.

The CivilWeb Heavy Duty Concrete Pavement Design spreadsheet can be purchased further down this page for only £10. Alternatively the heavy duty concrete pavement design spreadsheet is included in the CivilWeb Rigid Pavement Design Suite which includes 11 different pavement design methods along with a number of other useful design tools including concrete flexural strength calculators. Follow the above link for full details.

Heavy Duty Concrete Pavement Design

Heavy duty concrete pavement design is very different from concrete road design. Road designs for highways are designed to accommodate a maximum axle load from a heavy good vehicle, typically around 80kN per axle. Heavy duty pavements in ports, airports and heavy industrial sites are often required to accommodate much larger axle loads. Heavy duty concrete pavement designs for axle loads of over 1,000kN are not uncommon.

Heavy duty concrete pavement designs need to take account of these much larger loads. Larger axle loads are capable of stressing the soil at a much greater depth than is the case for a typical 80kN highway axle load. For this reason, heavy duty concrete pavement designs cannot use the same empirical methods as highway design. A more detailed analysis of the pavement and soil stresses using the Westergaard method or finite element methods.

BPA Heavy Duty Concrete Paving Design Method

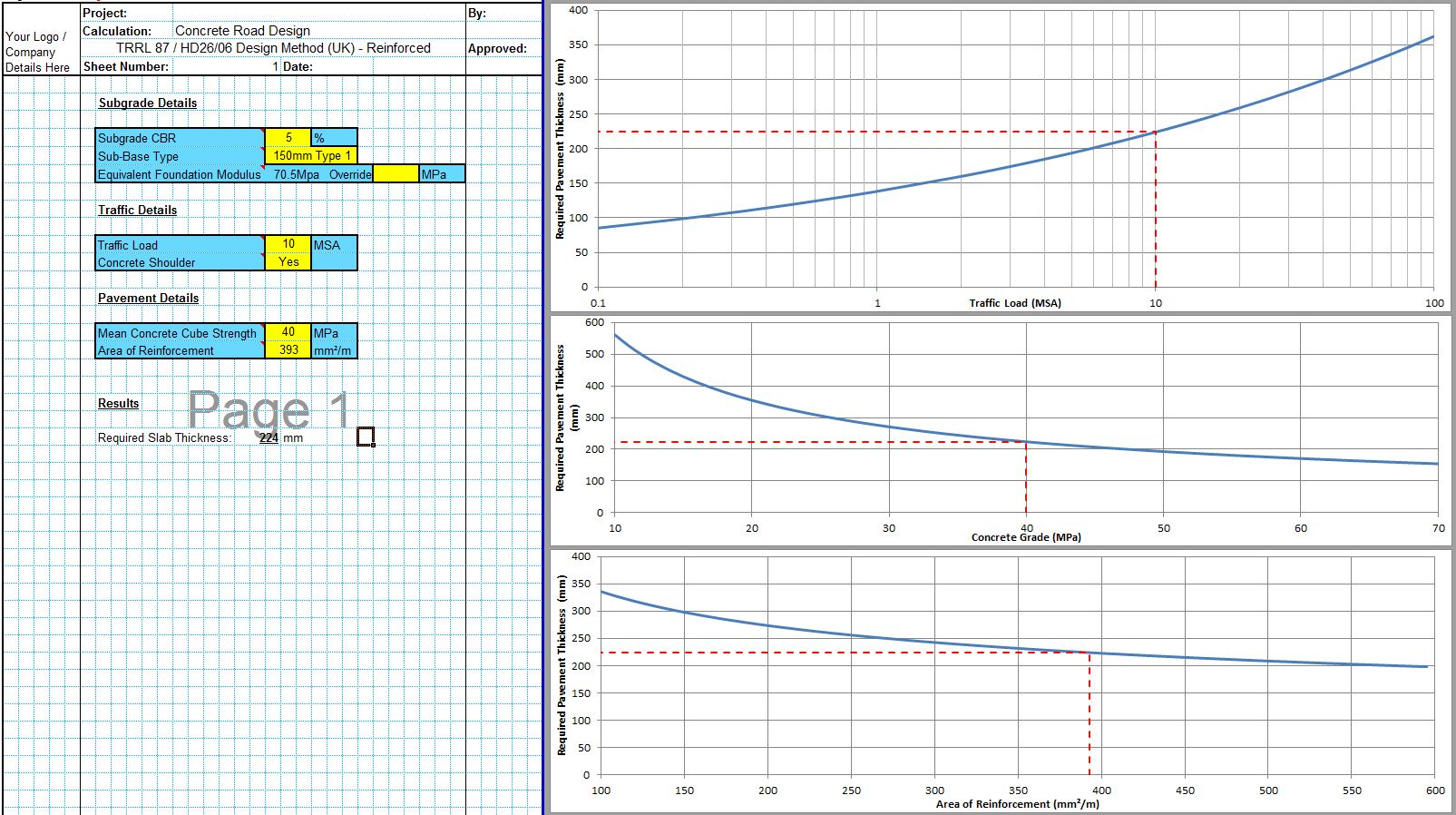

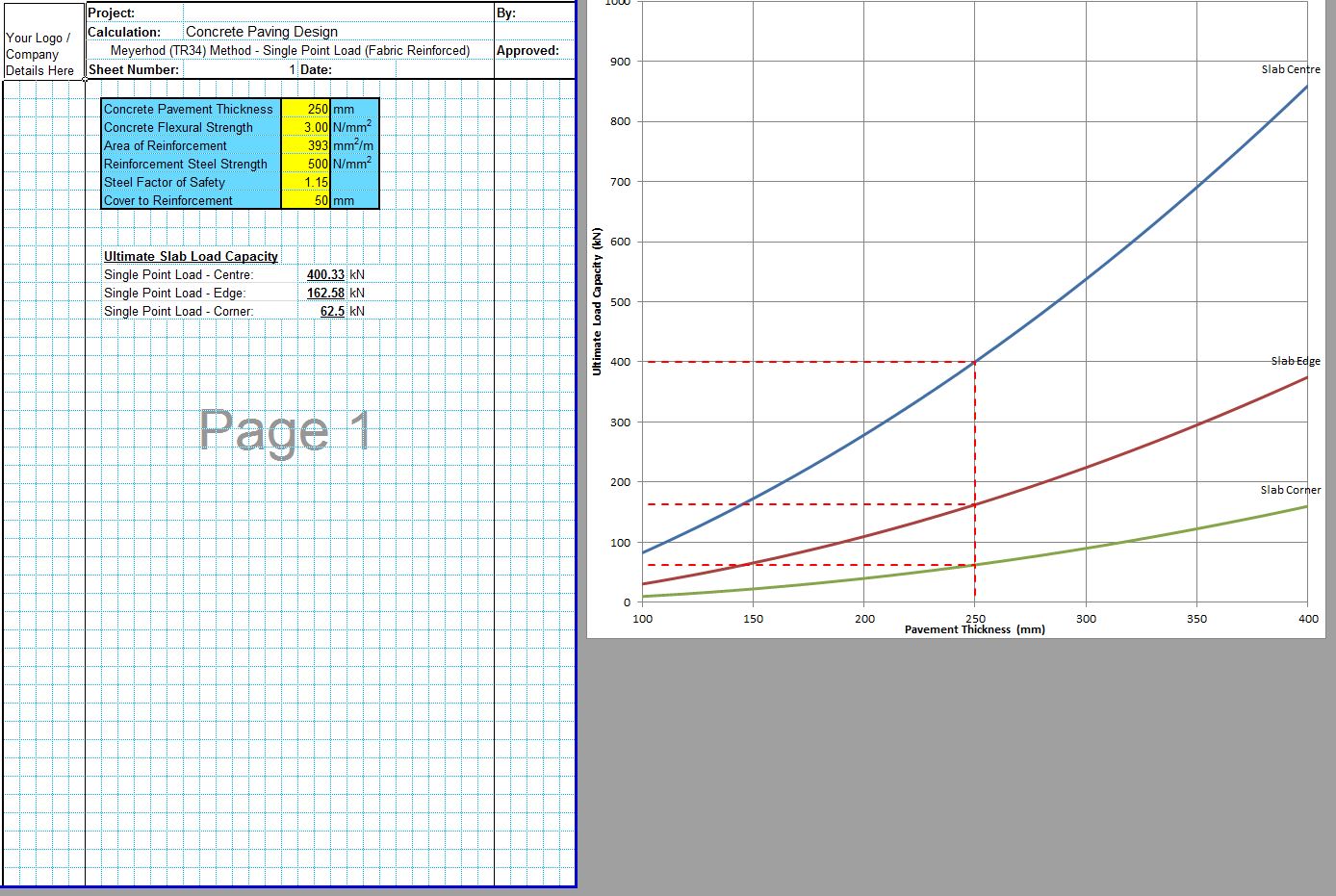

Many of the methods used for the design of concrete pavements are based around empirical equations which have evolved around standard highway traffic. These often include factors to adjust the findings for non-standard axle loads and tandem axle arrangements, however these are not really suitable for the design of concrete pavements to suit very heavy duty wheel loads.

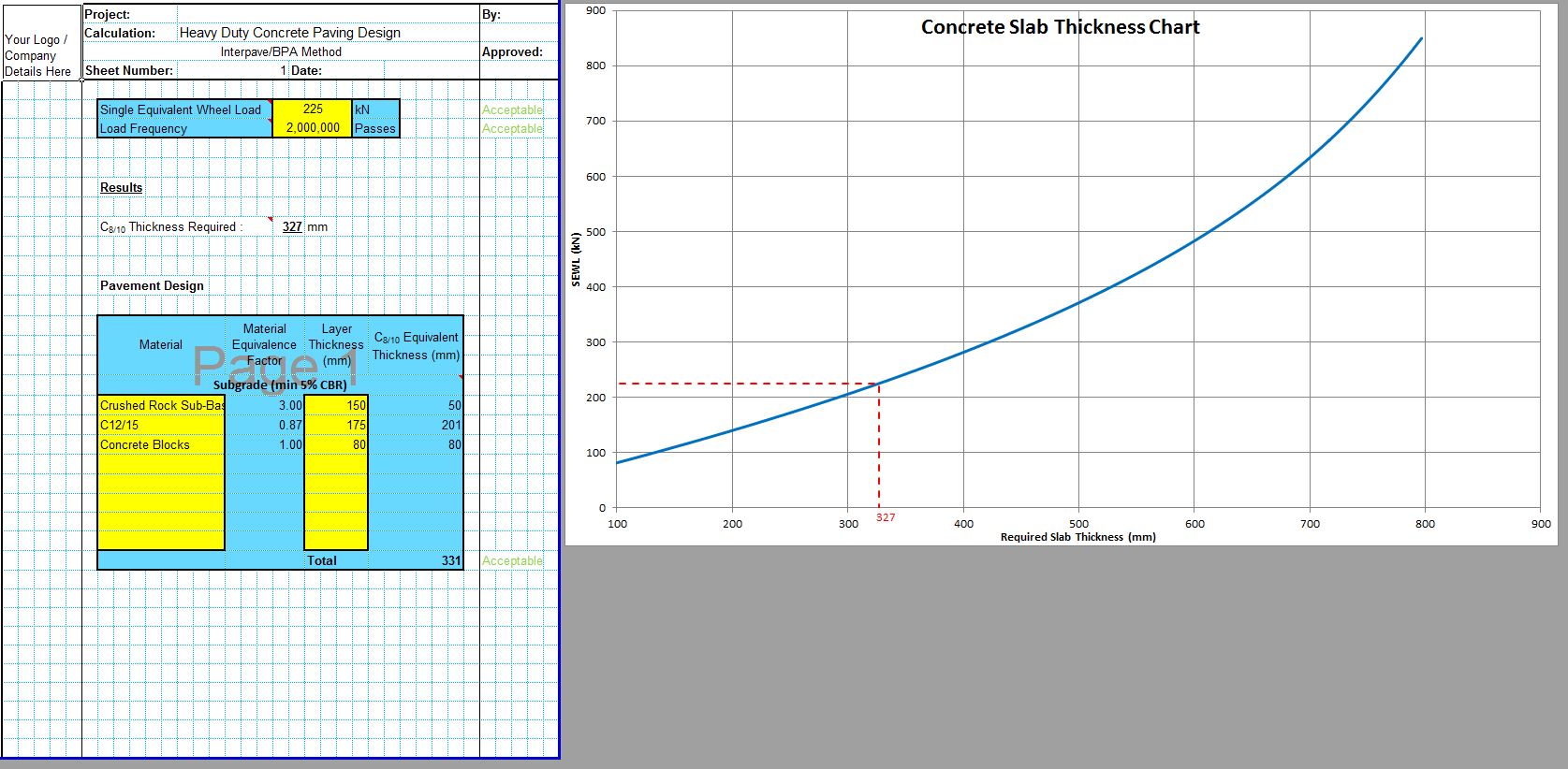

The British Ports Association developed a design method for concrete pavements subject to extremely heavy wheel loadings such as those from reach stackers and similar container handling equipment commonly used in ports. The latest version of this guidance has been published by the concrete block paving association Interpave, and focuses on heavy duty concrete pavement design using concrete blocks.

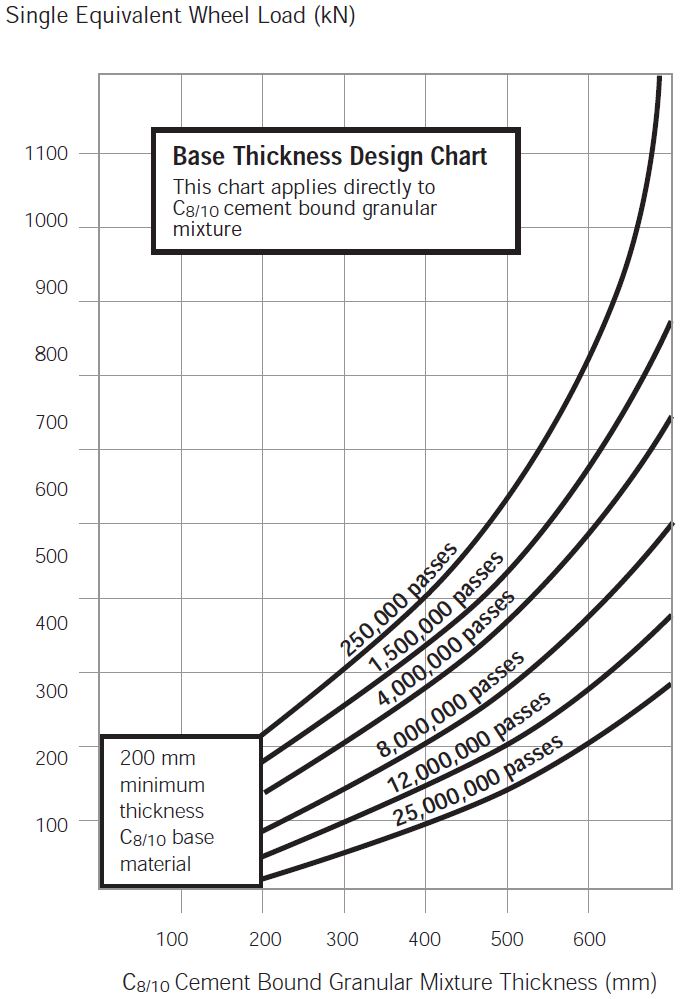

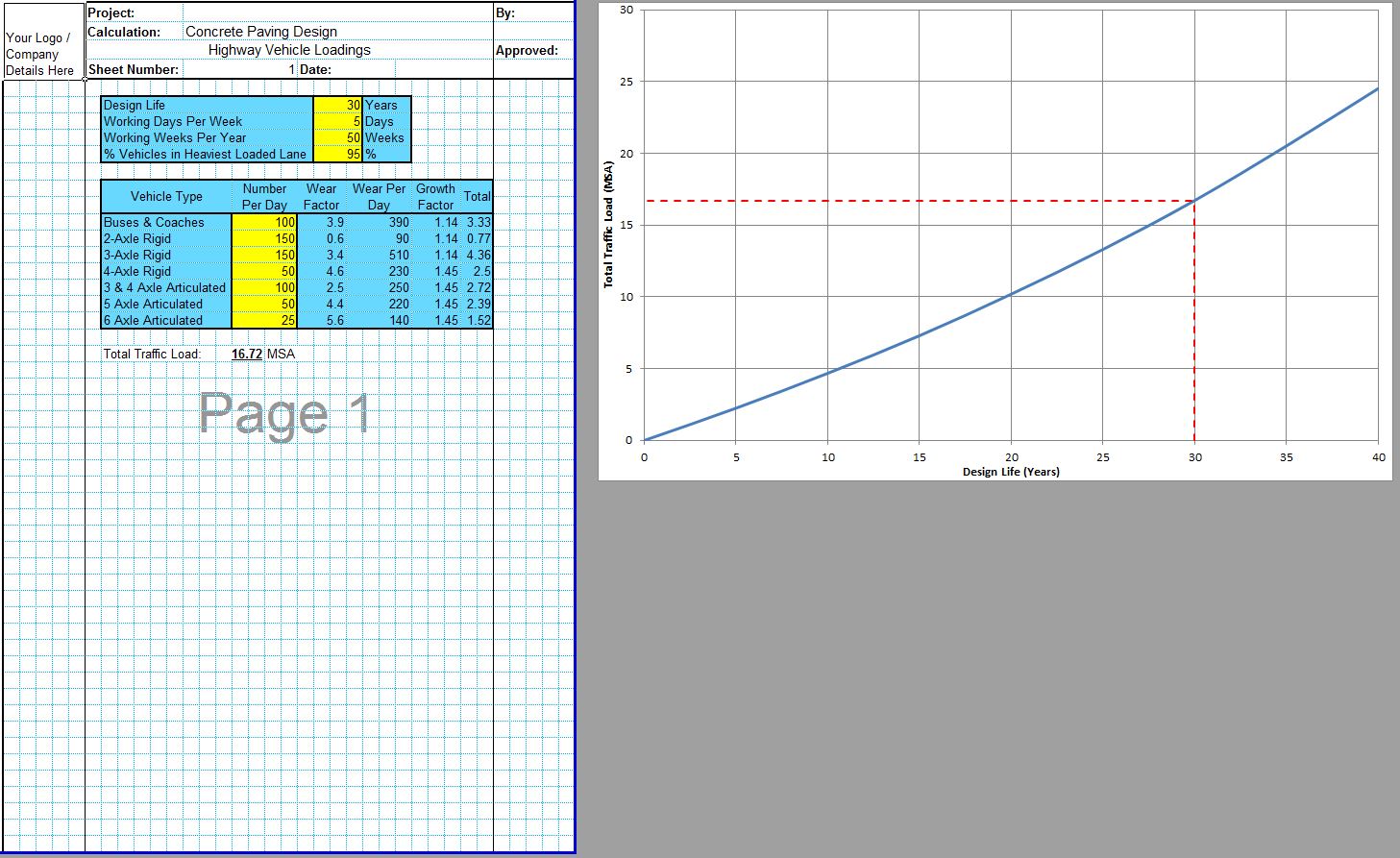

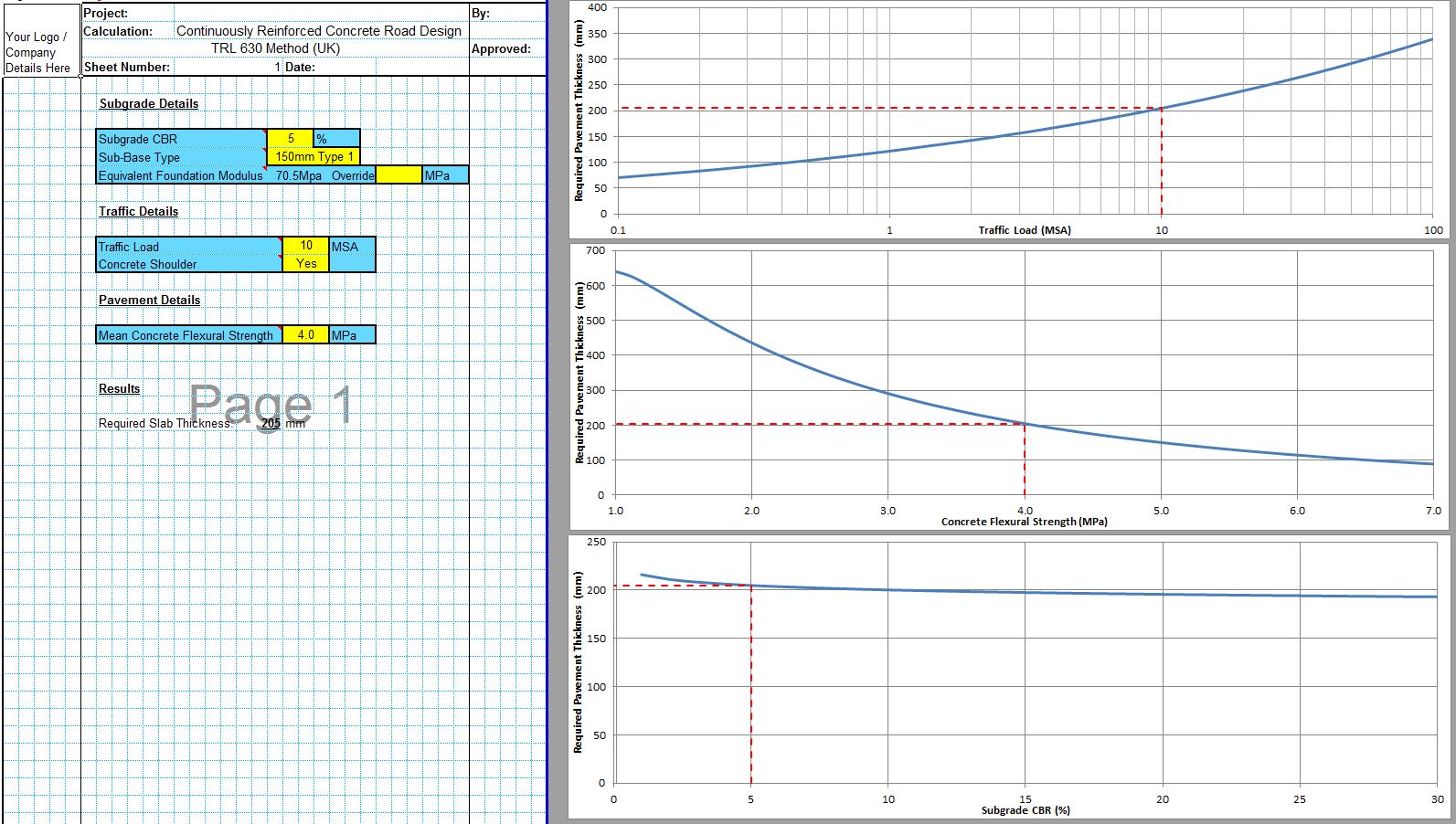

The BPA method is based on finite element modelling of heavy duty pavements subjected to heavy wheel loads. The finite element model has then been calibrated using performance data from real pavements. The finite element data has then been collated with a fatigue relationship into a very simple design chart which can be used to design the pavement. This chart is included on the following page.

Equivalent Single Wheel Load

The BPA method simplifies the axle loadings into an equivalent single wheel load (referred to as a SEWL or single equivalent wheel load in the guide). Further information on determining the SEWL is given in our Equivalent Single Wheel Load post.

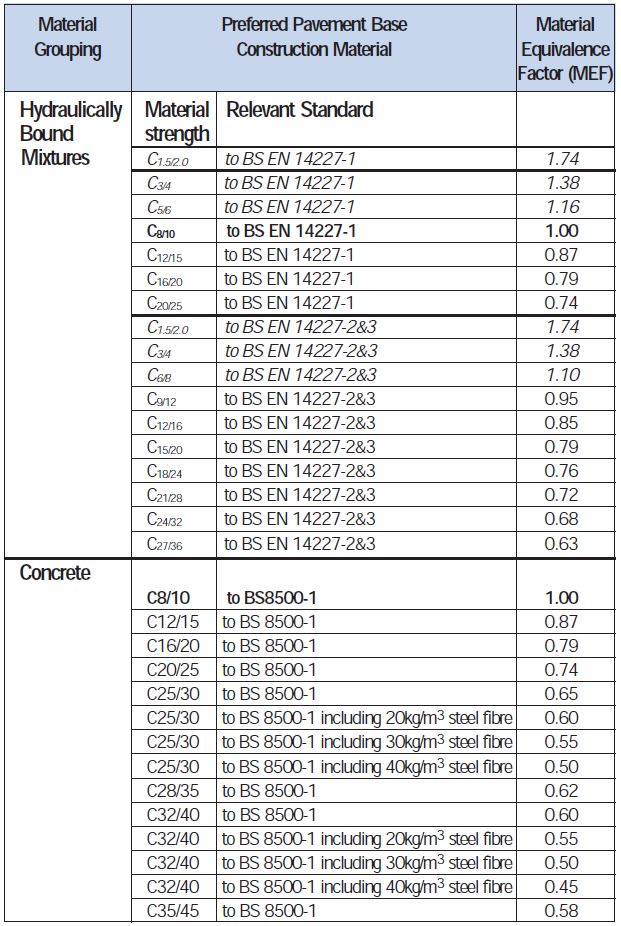

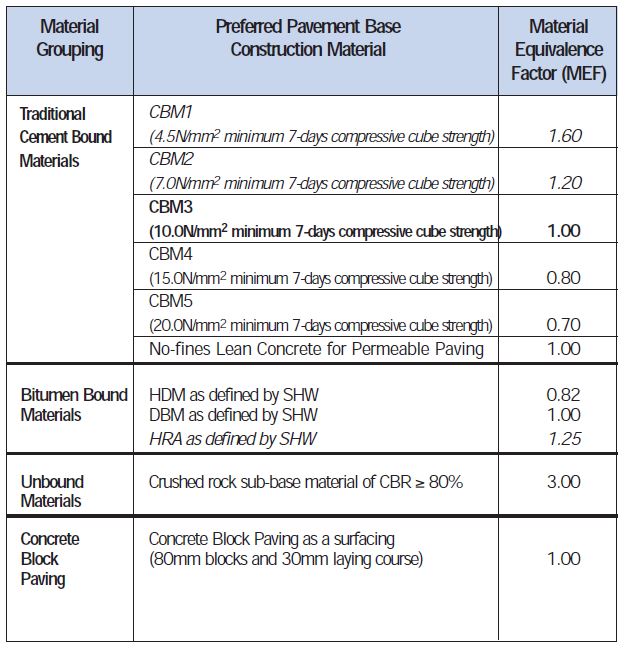

Material Equivalence Factors

The design chart presented is based on a single type of pavement material, a C8/10 concrete. The results from this design chart then need to be converted to suit the required pavement material. This is done using a material equivalence factor as shown in the tables reproduced below.

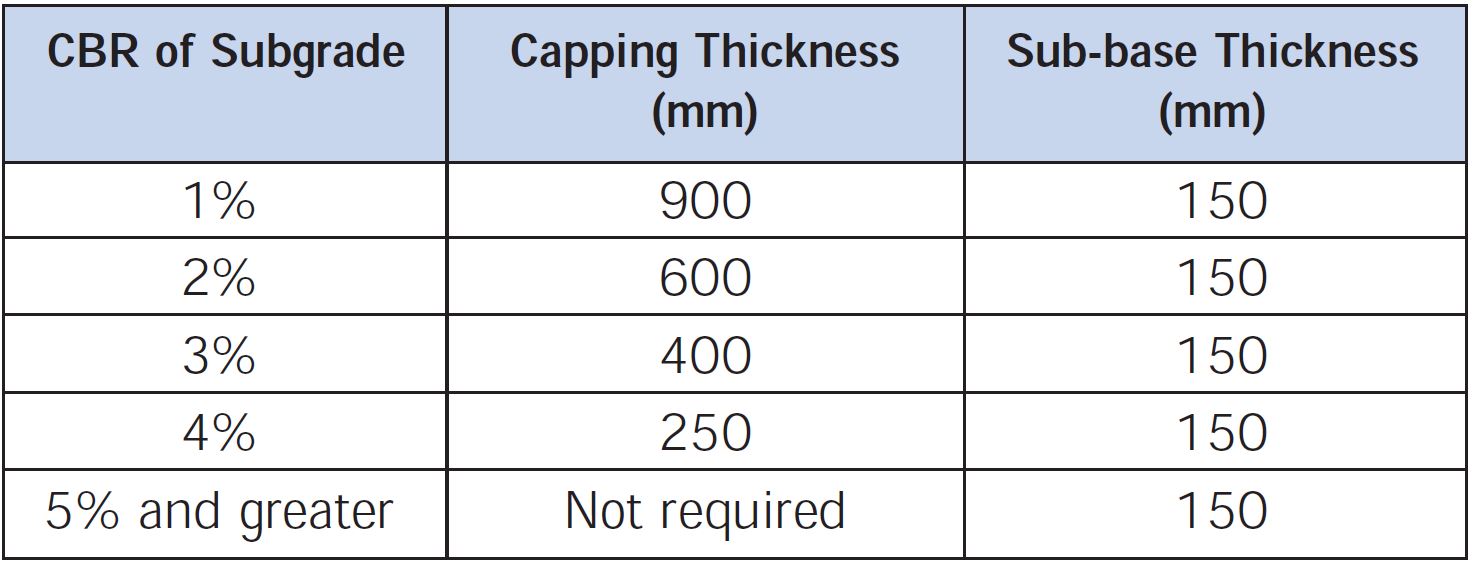

Subgrade

The heavy duty concrete pavement design chart presented in the guide assumes that the subgrade will have a CBR value of at least 5% and the pavement will include a 150mm thick layer of Type 1 sub-base. Where the subgrade does not achieve 5% CBR, the guide includes guidance on the amount of capping material which should be installed to compensate for the lower strength of the subgrade.

The guide notes that these values are considerably thicker than standard highway pavement recommendations. This is because heavy loads affect the subgrade at much deeper depths than standard highway loadings. For this reason it is advised that greater depths of capping material are used when the subgrade does not achieve 5% CBR. This guidance is shown in the below table.

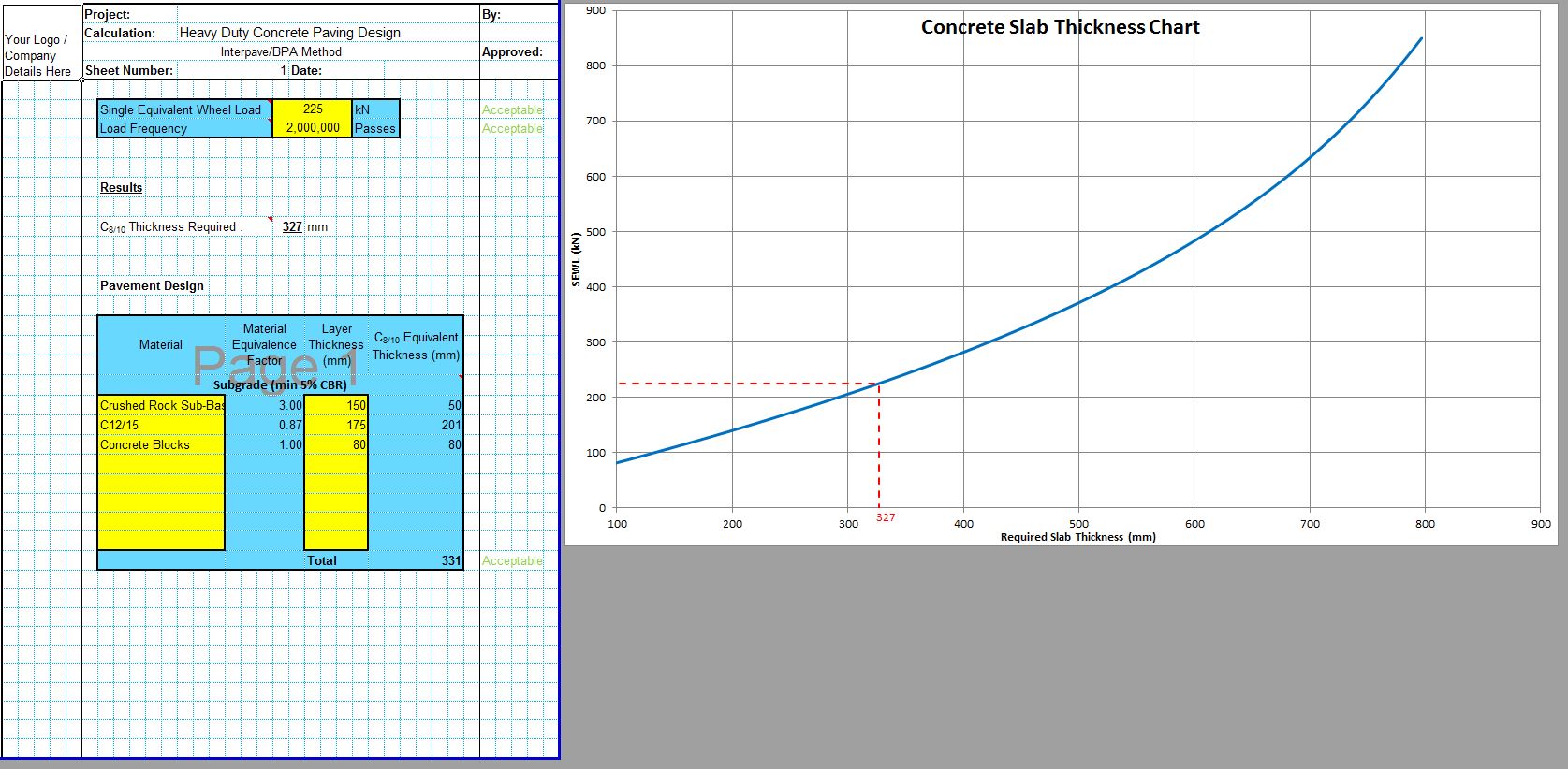

CivilWeb Heavy Duty Concrete Pavement Design Spreadsheet

Our unique design spreadsheet allows the designer to complete a heavy duty concrete pavement design in accordance with the BPA/Interpave method. The spreadsheet is very easy to use and a compliant design can be completed in seconds. Our unique analysis tools also allow the designer to see at a glance how the design can be optimised. Buy now for only £10.

Or why not buy our full Rigid Pavement Design suite for only £20

Or buy our best value bundle, the full Pavement Design Suite including flexible and rigid pavement spreadsheets for only £30

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.