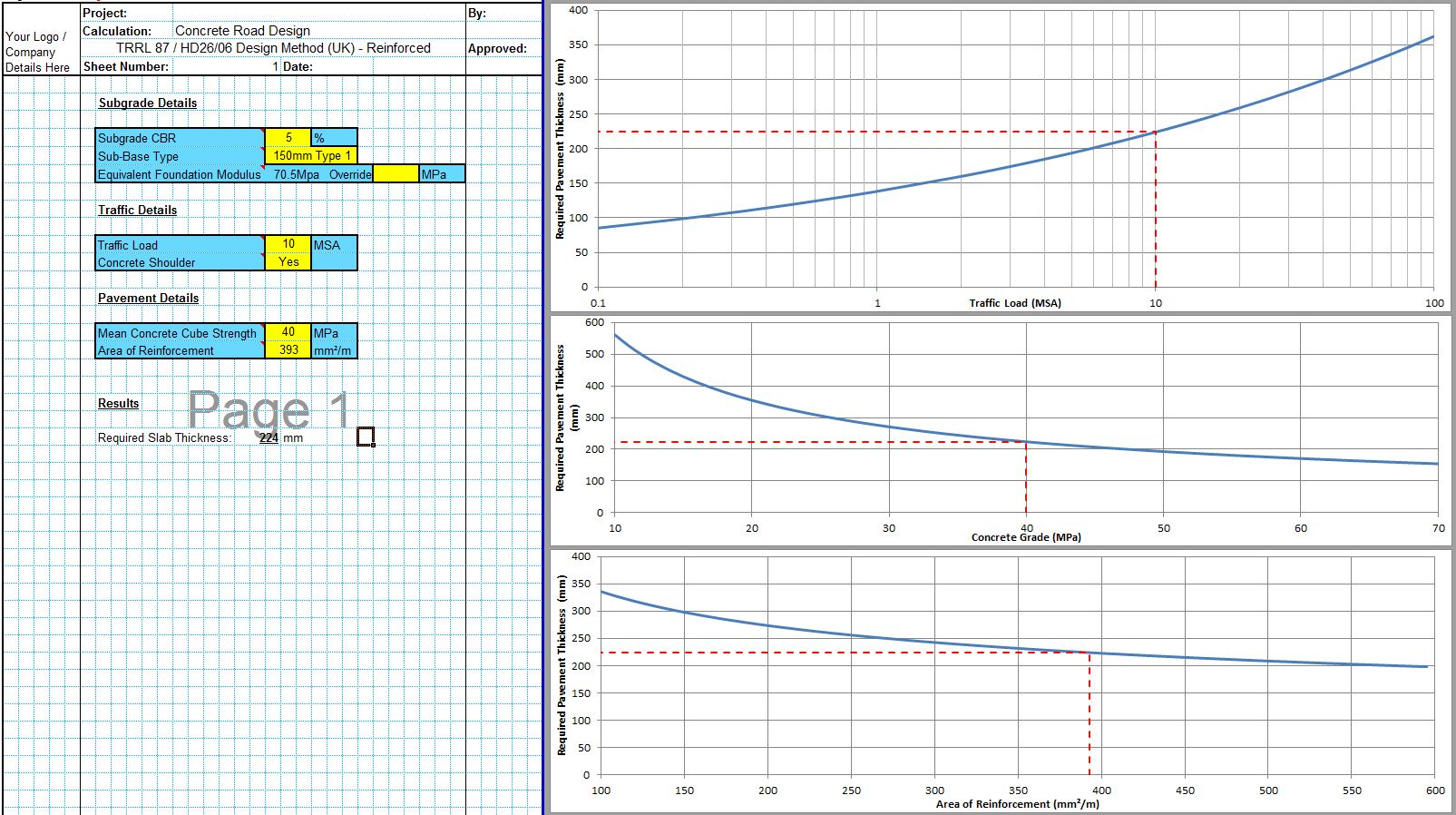

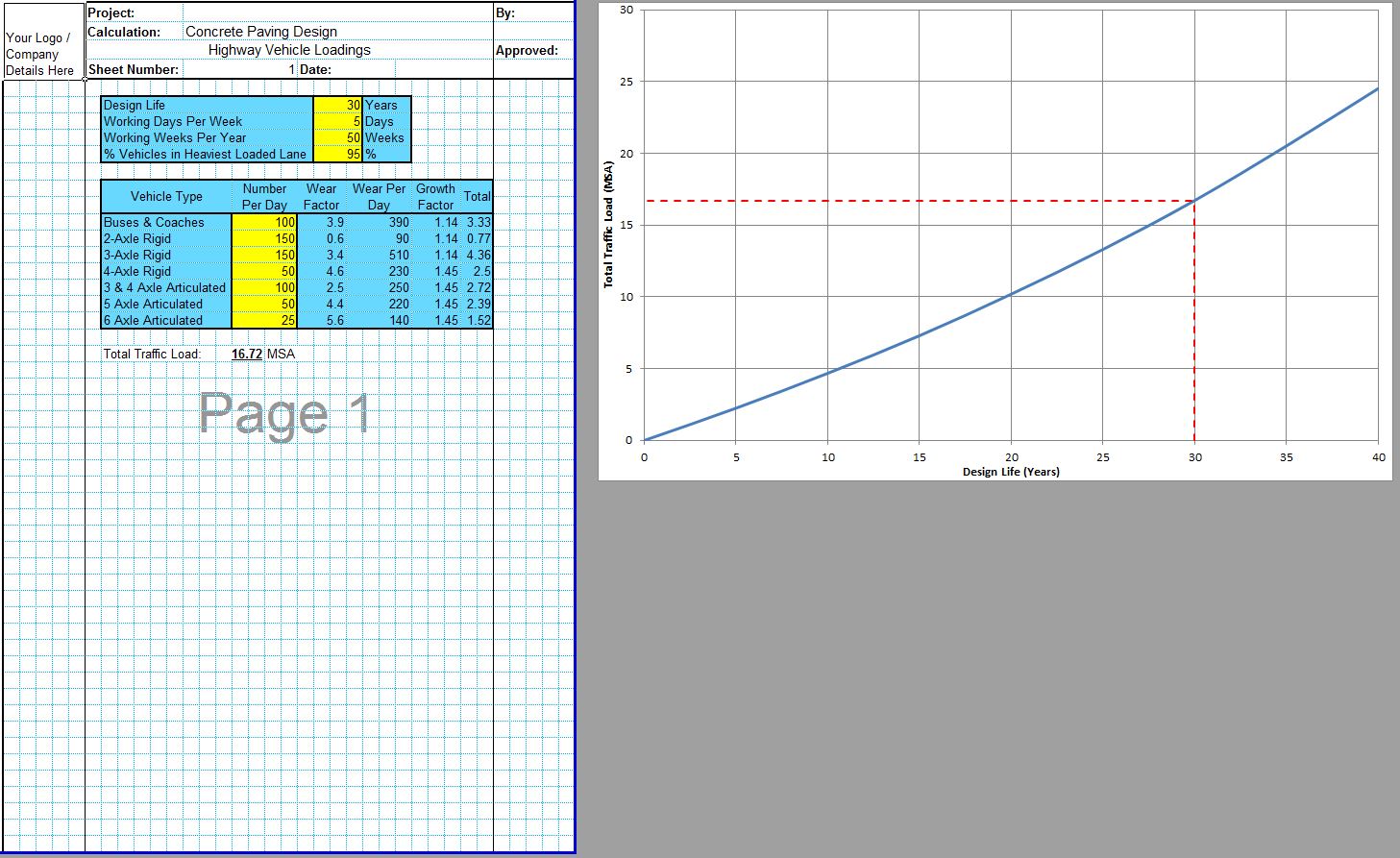

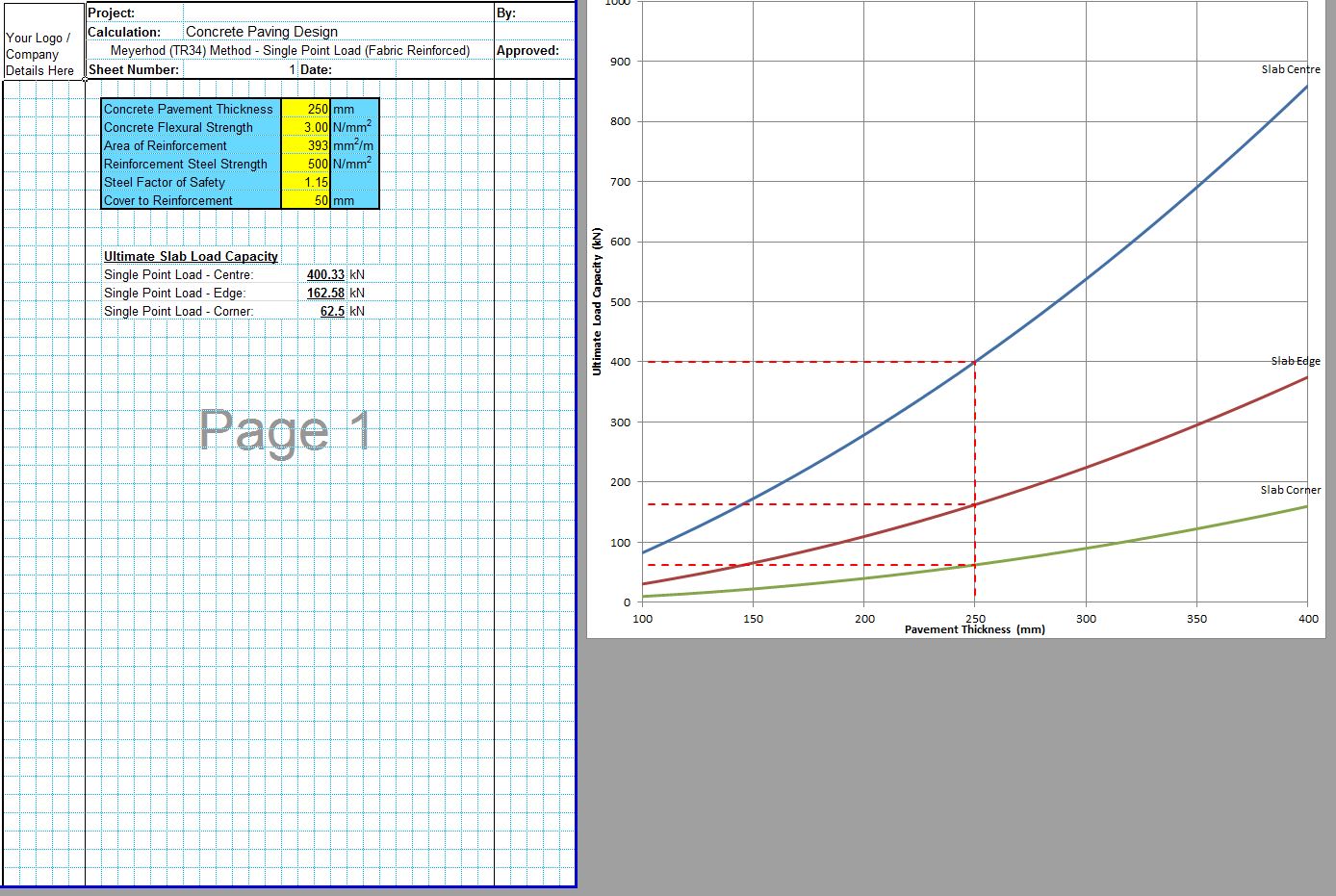

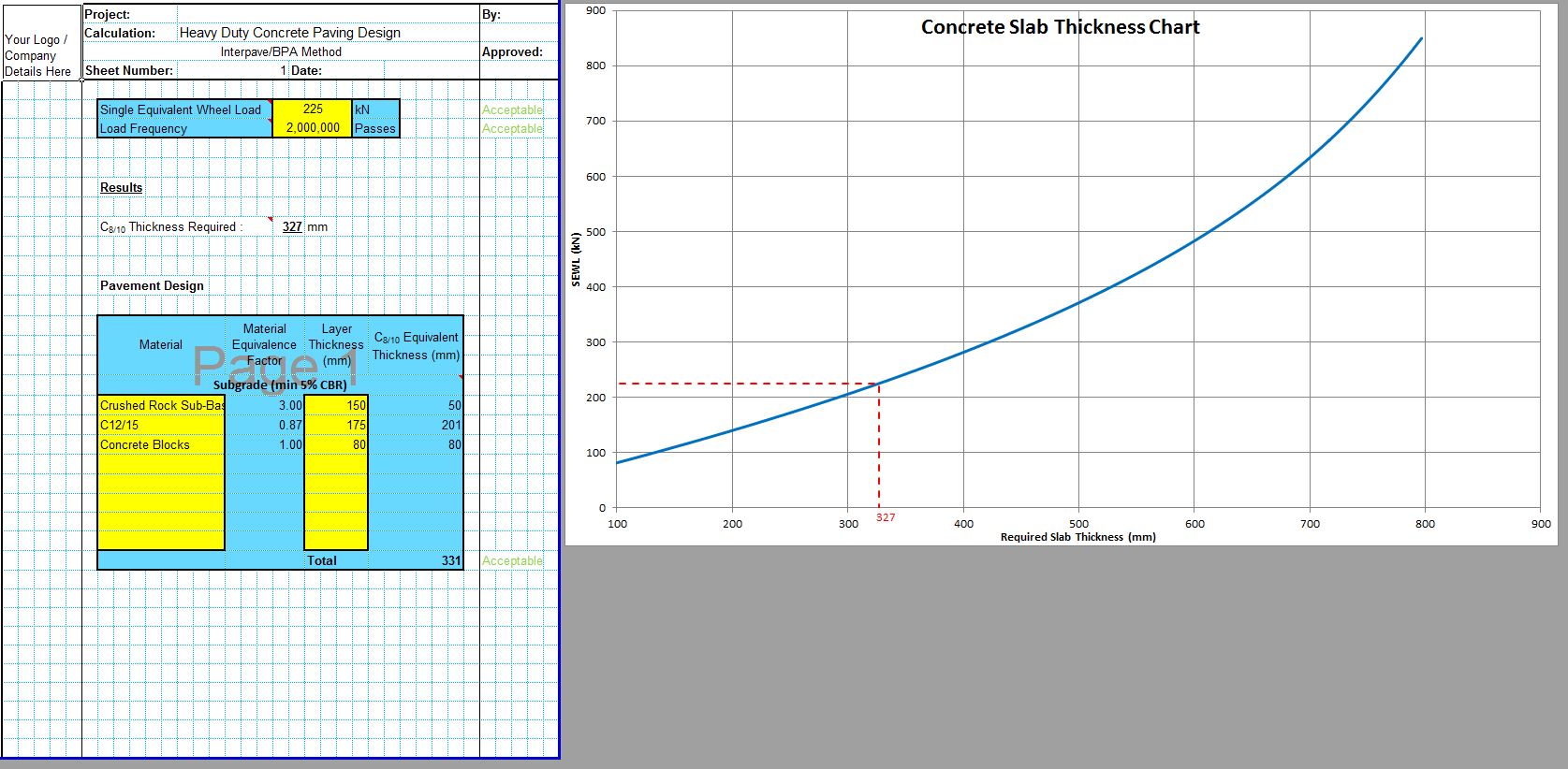

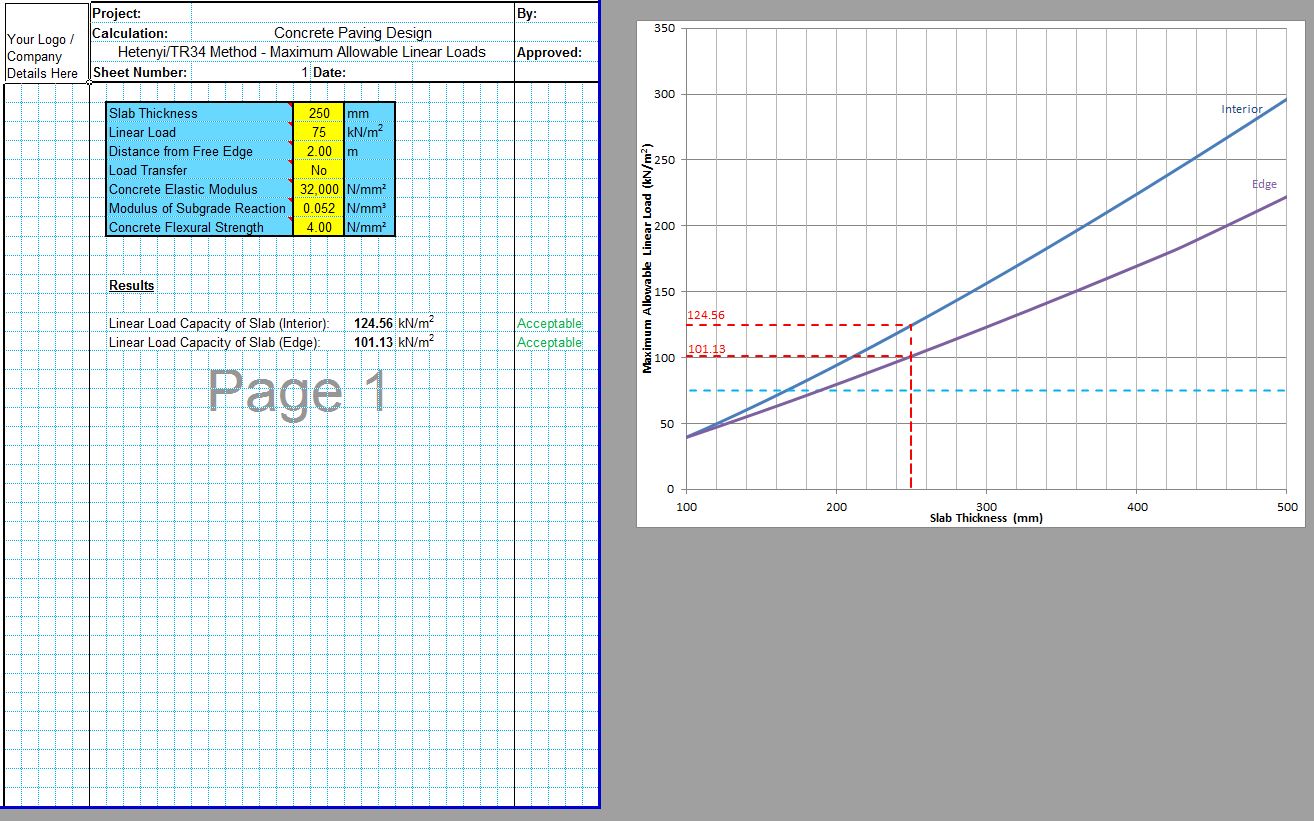

The Concrete Society Technical Report 66 deals with the design of external pavements for highway or similar loadings. For this reason Concrete Society Technical Report 66 follows the guidelines laid down in the UK concrete road design manual TRL 87. This differs from the Concrete Society Technical Report 34 which deals with internal pavements subjected to static loads rather than dynamic wheel loads.

The CivilWeb Concrete Society Technical Report 66 Concrete Pavement Design Spreadsheet allows the designer to complete concrete pavement designs in accordance with Concrete Society Technical Report 66 in seconds. Plus our unique design tools allow the designer to see at a glance exactly where the design can be optimised, saving time on iterative design approaches.

The CivilWeb Concrete Society Technical Report 66 Concrete Pavement Design spreadsheet is available for purchase at the bottom of this page for just £10. Alternatively the Concrete Society Technical Report 66 spreadsheet is included in the CivilWeb Rigid Pavement Design Spreadsheet Suite which includes 11 different pavement design methods along with a number of other useful design tools including concrete flexural strength calculators. Follow the above link for full details.

Concrete Society Technical Report 66

Included in the Concrete Society Technical Report 66 is a simplified method of applying the TRL 87 design model for highway loading on concrete pavements. Though jointed concrete roads are not generally used for highways in the UK anymore, the simplified TR66 method is still extensively used for the design of industrial concrete roads and pavements subjected to highway type loadings.

The TR66 method simplifies a number of the TRL 87 input parameters;

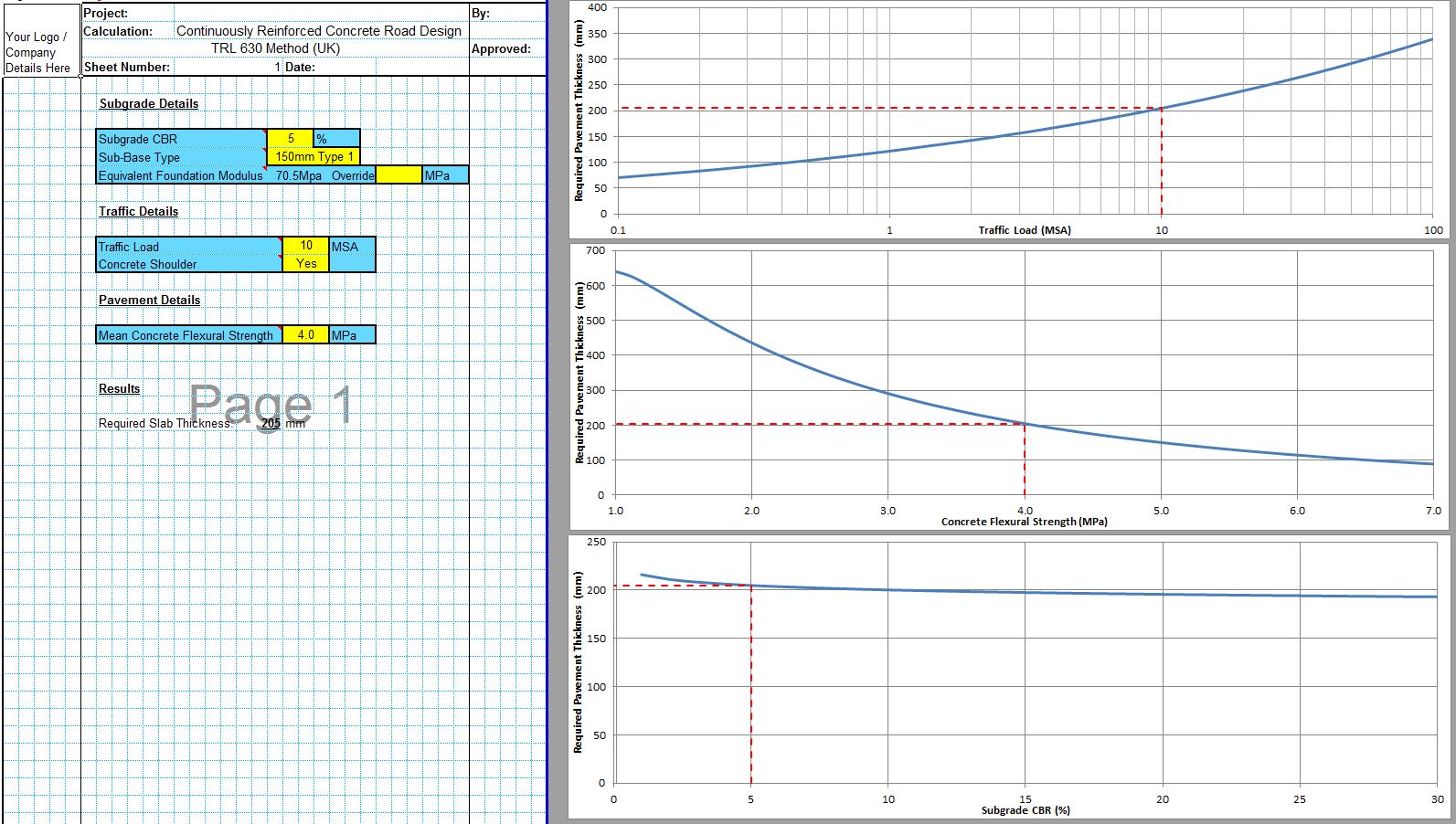

- Equivalent Foundation Modulus – This is the most difficult of the TRL 87 parameters to determine. TR66 simplifies this input by relating it to a relationship of subgrade CBR and two commonly specified sub-base types. Subgrade CBR is the most common measure of the subgrade support for concrete pavements so this is easy to obtain from onsite testing. Then either 150mm Type 1 Sub-Base or 150mm Hydraulically Bound Material (HBM) Sub-Base is added. TR66 recommends a calculation which converts these parameters to an equivalent foundation modulus value for use in the TRL 87 model.

- The mean concrete cube compressive strength values are assumed for three common pavement quality concrete strength specifications (C28/35, C32/40 and C40/50).

- Concrete pavements are assumed to be unreinforced unless 300mm2 of reinforcement is present per metre width in the bottom of the slab.

Concrete Society Technical Report 66 - Design Tables

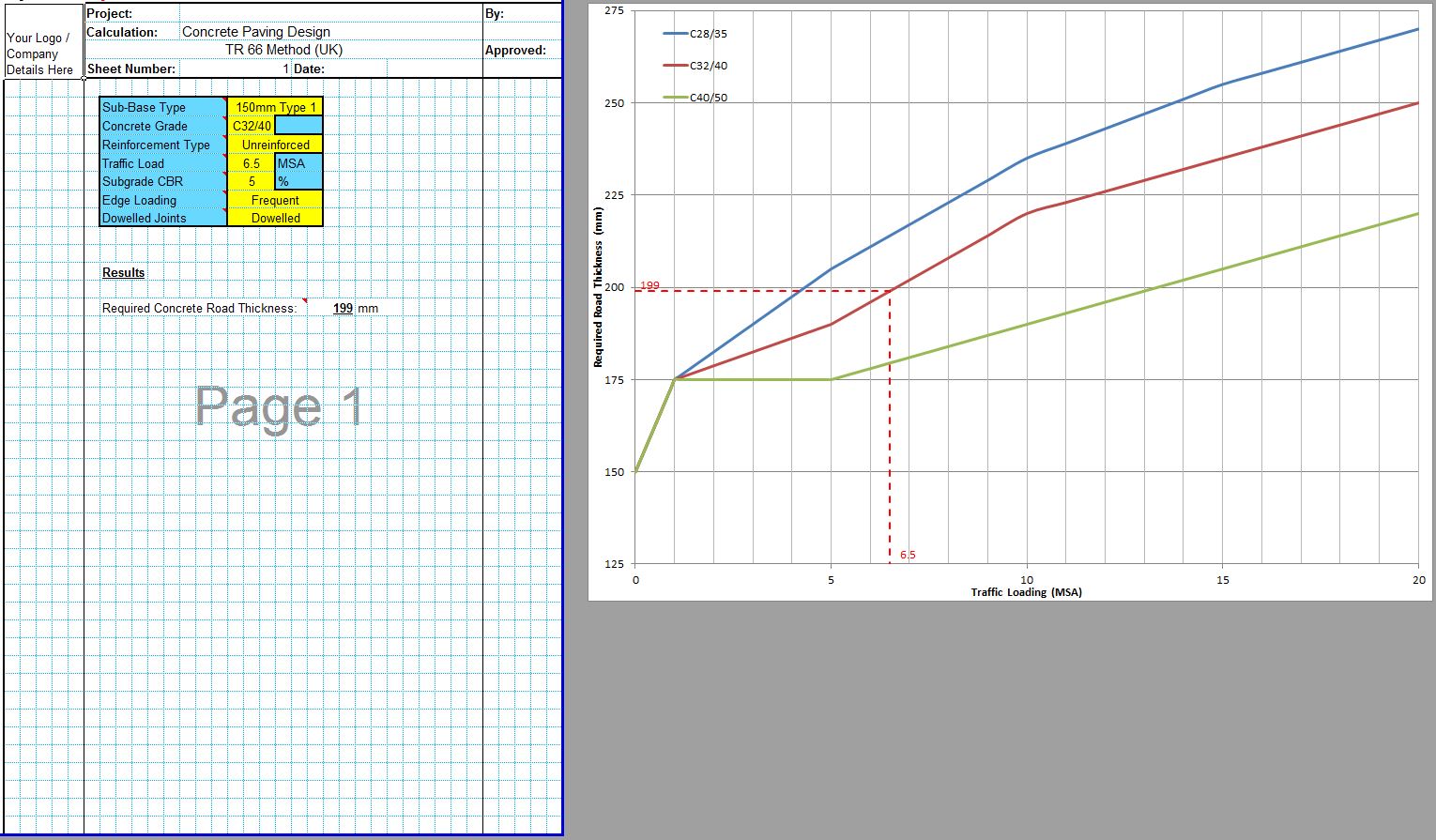

TR 66 then compiled a set of standard design tables calculated using the TRL 87 model and the above assumptions which the designer can simply pick a concrete thickness based on subgrade strength, sub-base type, edge loading conditions, concrete grade and reinforcement and traffic loading. These design tables assume that the joints are dowelled which is recommended. If the joints are to be left undowelled it is recommended that 40mm is added to the tabulated values.

CivilWeb Concrete Society Technical Report 66 Concrete Pavement Design Spreadsheet

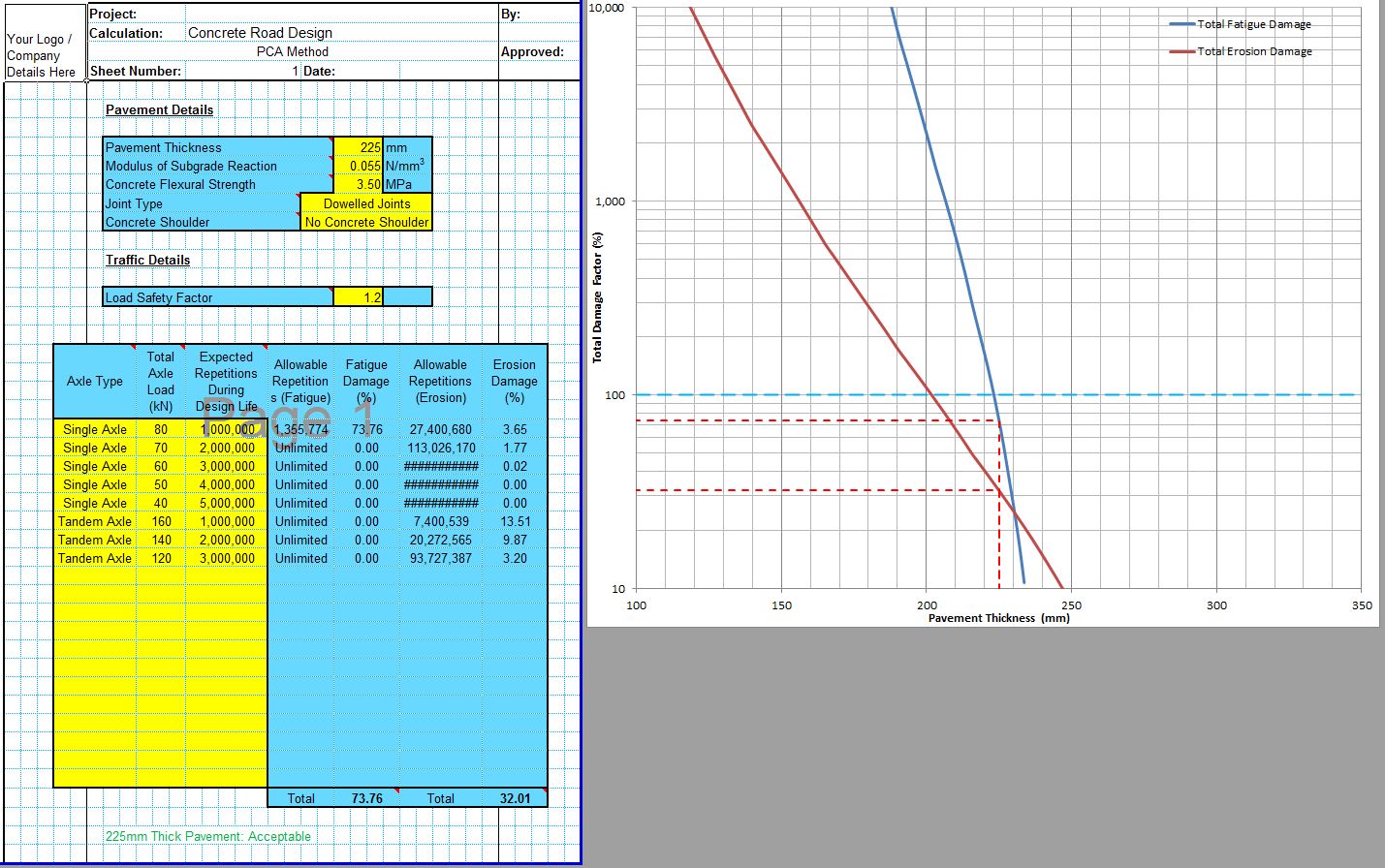

The CivilWeb Concrete Society Technical Report 66 Concrete Pavement Design Spreadsheet automatically interpolates a design thickness using the TR66 design tables. This allows the designer to complete a fully compliant concrete pavement thickness design in seconds. The spreadsheet also includes a unique design tool showing the thickness results for alternative designs allowing the designer to see at a glance whether the design can be optimised.

Buy now for only £10

Or why not buy our full Rigid Pavement Design suite for only £20

Or buy our best value bundle, the full Pavement Design Suite including flexible and rigid pavement spreadsheets for only £30

Download Free Trial Version

To try out a fully functional free trail version of this software, please enter your email address below to sign up to our newsletter.