The compressive strength of road pavements is commonly specified in concrete road and pavement specifications. This however is slightly odd in that the compressive strength is not a critical parameter for pavement performance, the flexural strength is much more important from a structural point of view. Other parameters such as permeability are also far more important for durability of the pavement than the compressive strength. So why is compressive strength often specified?

There main reason why compressive strength is specified even though it is not in itself critical is because concrete cube tests which determine compressive strength are simple, accurate and well understood. The flexural strength test is expensive, difficult and not particularly accurate. While the compressive strength is not important in itself, it does correlate with the flexural strength and also gives an indication of the density and permeability. For this reason compressive strength is still specified and measured in concrete pavements.

Compressive Strength to Flexural Strength Conversion Tool

The CivilWeb Flexural Strength of Concrete Spreadsheet includes a useful tool which can be used to convert compressive strengths to flexural strengths using two published methods. This useful calculator tool is available for purchase for only £5 at the bottom of this page. Further details are included in our Compressive Strength to Flexural Strength Conversion post.

Specified Compressive Strength of Concrete Roads Pavements

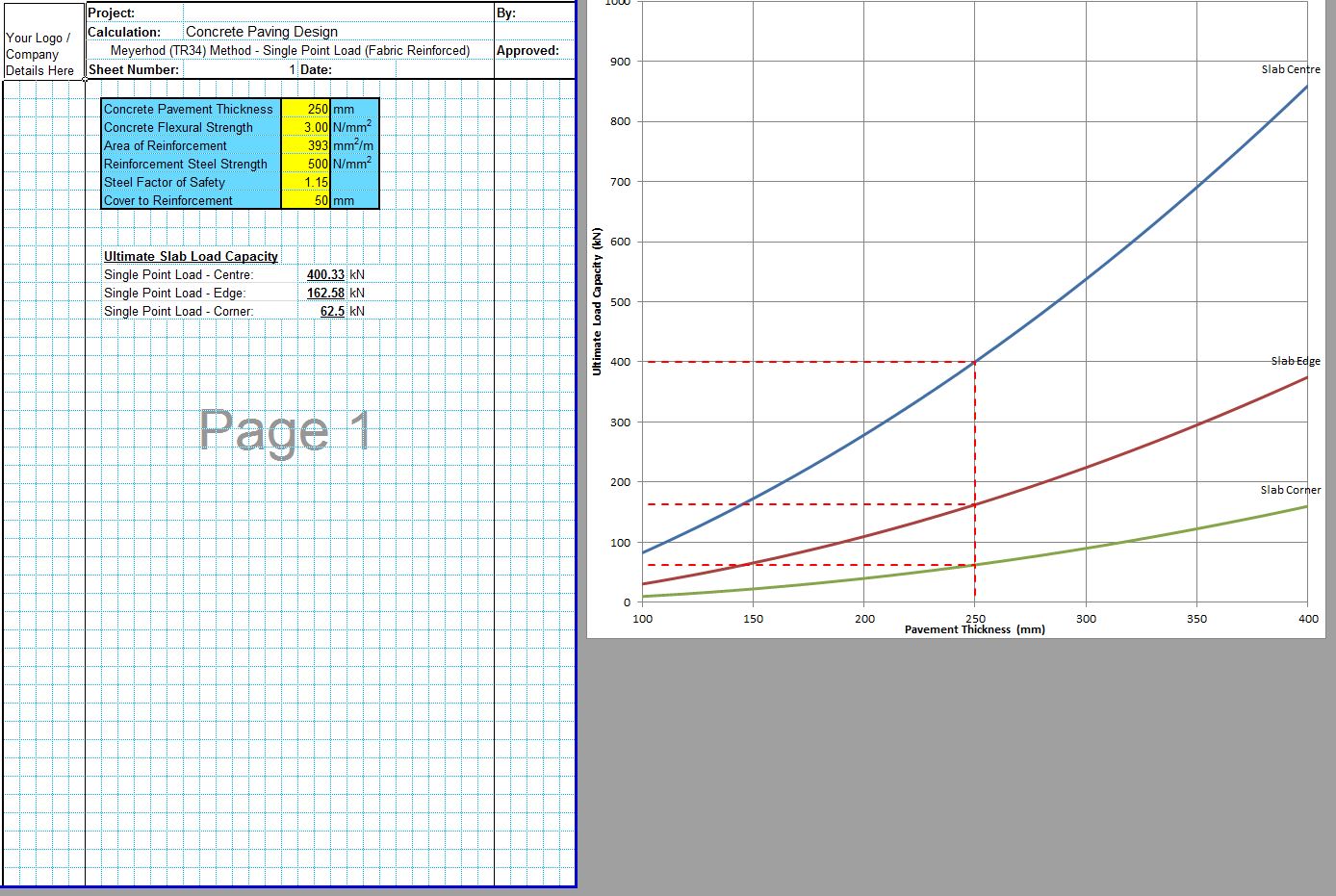

The critical design parameter for concrete pavement design is usually the concrete’s flexural strength, sometimes known as the modulus of rupture. However the flexural strength of the concrete is difficult and expensive parameter to measure and the test is not very precise. For this reason it is common practice to specify a required flexural strength, measure the concrete’s compressive strength and then use a calibrated relationship between the two parameters to check compliance.

This gives the advantage that compressive strength is relatively easy to determine, but it does introduce an element of doubt regarding the proper relationship between compressive strength and flexural strength which is slightly different for each concrete mix.

The compressive strength of the concrete measures its ability to resist forces trying to push the concrete together. The compressive strength of the concrete is not important of itself for the performance of the concrete pavement as the loads on a concrete pavement result in bending. While this bending creates both compressive and tensile stresses in the pavement, concrete is much stronger in compression than in tension so the pavement never fails due to a lack of compressive strength.

The compressive strength of the road pavement is never the critical design parameter. It is only used as an indicator of the concrete’s flexural strength. Indeed the compressive strength of the concrete is not a good indicator of the concrete road pavements performance or the concrete’s quality either as none of the likely critical durability or quality issues for concrete pavements can be assessed directly from the compressive strength alone. It is true that clients are often fixated on compressive strength results even though they are not critical in themselves. Compressive strength is often specified despite this because it is used as a simple indicator of the concrete’s flexural strength.

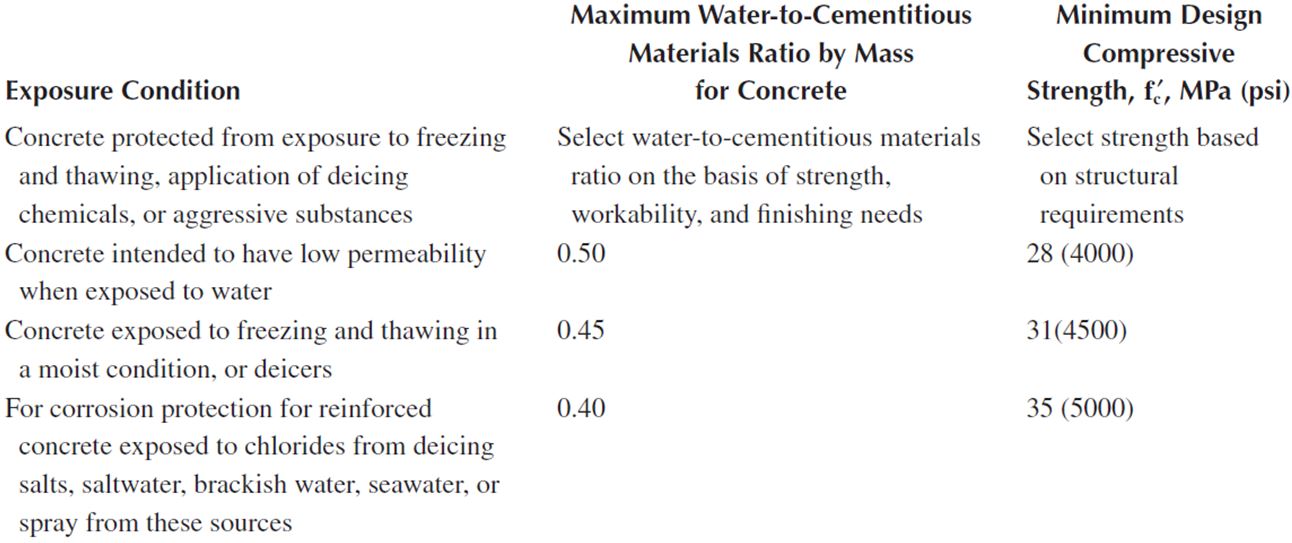

Increased compressive strength requirements are also often made in order to improve the concrete’s resistance to freeze-thaw cycles, de-icers, chlorides, sulfates, seawater and other chemicals which may attack the concrete. In this case the compressive strength is being used as an indicator for the permeability. Again this is often deemed reasonable as a denser, less permeable concrete is generally made by increasing the cement content, which also improves the compressive strength. Some standards specify minimum compressive strength requirements for certain conditions such as the below table taken from the PCA in the US. In the UK it is recommended that a minimum compressive strength class of C32/40 is used in order to achieve suitable durability, regardless of the structural strength requirements.

Characteristic Compressive Strength of Road Pavements

Concrete road pavements are usually specified and designed using the characteristic compressive strength at 28 days. This refers to the strength value which 95% of samples will exceed after 28 days curing in laboratory conditions. Note that any cores taken from the pavement after 28 days curing insitu will usually achieve much lower strength values.

As explained above the compressive strength is not important for road pavement design, but is used as a proxy for flexural strength. For this reason characteristic 28 day compressive strength of the concrete is used along with a defined relationship between compressive strength and flexural strength for this particular concrete mix.

A calculator tool for determining the relationship between the mean compressive strength measured onsite and the characteristic compressive strength specified is included with the CivilWeb Compressive Strength of Concrete Calculator spreadsheet. This can be used to analyze compressive strength test results to see whether they comply with the specified characteristic strength. This spreadsheet costs only £5 and can be purchased at the bottom of this page.

Typical Compressive Strength of Road Pavement Specifications

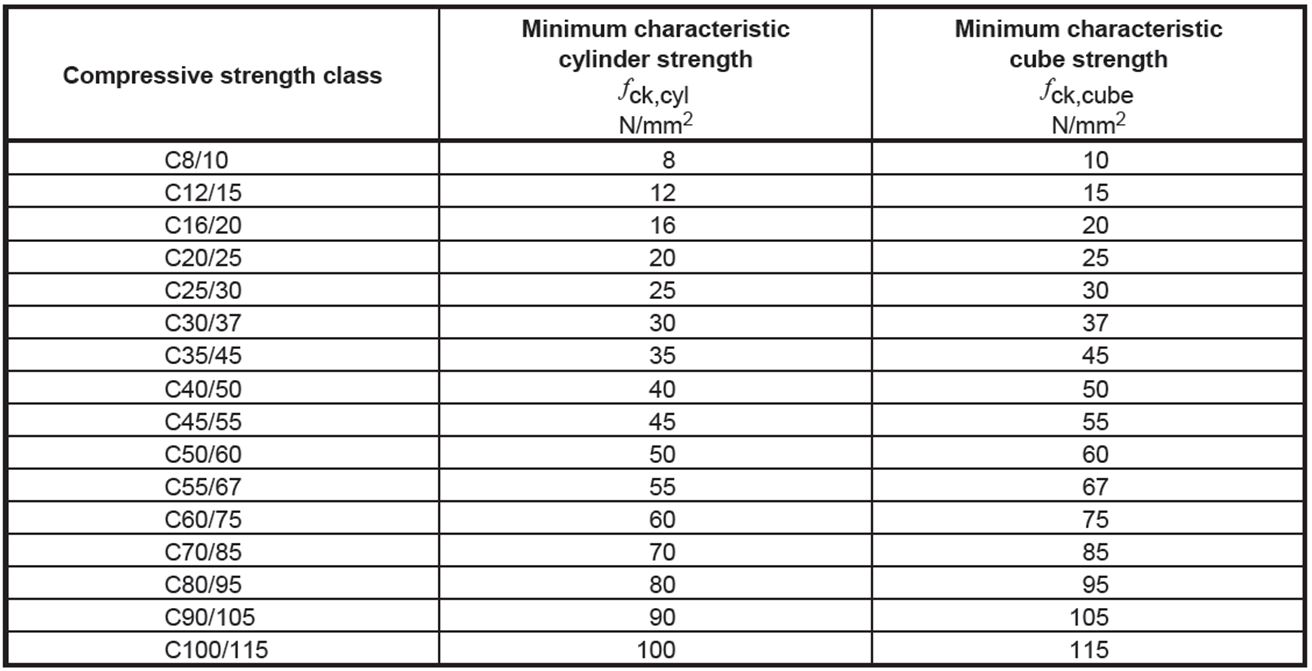

In the UK it is typical to measure the compressive strength of concrete buy crushing a 150mm cube sample taken onsite and cured in a laboratory. In the US and much of Europe it is more common to crush a cylindrical sample. To avoid confusion the compressive strength is specified using two numbers, the lower cylindrical value and the corresponding higher cube value, with the prefix C which denotes normal density concrete. This is shown in the below table taken from BS EN 1992. Further details are included in our Concrete Cube Test post.

Typical concrete compressive strength classes used for road pavements are between 20N/mm2 and 40N/mm2. Higher strengths are sometimes used but can lead to higher shrinkage and higher costs. This is usually only justifiable where extreme conditions are present such as highly abrasive operations or where high impact resistance is required. Otherwise the detrimental effects of higher shrinkage usually outweigh any benefits from higher strength. There is also often a drop off in correlation between high compressive strength and flexural strength which leads to diminishing returns.

Factors Affecting Compressive Strength of Road Pavements

The factors affecting concrete strength for pavements are similar to those affecting any structural concrete as described in our Compressive Strength of Concrete post. It is particularly important that the strength decreasing effects of air entrainment are considered for concrete pavements. Further information is included in our Air Entrained Concrete post.

While the required compressive strength of the road pavement needs to be adequate for the structural design and for durability requirements, additional strength can be detrimental to the concrete pavements performance. This is because stronger concrete tends to lead to greater drying shrinkage, increased curling, increased opening of joints and loss of load transfer and greater cracking can decrease the pavements life. For this reason care must be taken that none of the specification requirements such as cement content or minimum water-cement ratio do not inadvertently lead to over-strength concrete being installed with is attendant problems.

Concrete Compressive Strength Testing

The compressive strength of road pavements is generally measured in the same way as any concrete project. Concrete cube samples are taken when during the pouring of the concrete and then cured in the laboratory and crushed at a specified time, often 7, 14 or 28 days after pouring. Further details are included in our Concrete Cube Test post.

An alternative method would be to undertake strength testing on concrete cores as described in BS EN 13877-2. This method take account of the workmanship and site curing conditions so can be considered to be a more reliable measure of the concrete’s insitu compressive strength. These cores can also be used to verify the pavement thickness using the method described in BS EN 13863-3.

This method is however more expensive and the cores will need to be filled with a suitable high strength non-shrink grout. The results from these cores are usually lower than for the cube tests. Even the best workmanship and curing onsite are not going to replicate the laboratory cured samples. The compressive strength of cores taken insitu are usually around 70% - 85% of the laboratory samples. This method is often used when cube test results fall below the required value to check the quality of the concrete insitu in case of an error with the laboratory results.

Compressive Strength of Road Pavements - Maturity

The strength requirements for concrete road pavements are usually given for the 28 day strength as this is a convenient round number (in weeks) and concrete road pavements are often left un-trafficked for around a month after construction. However for quality control purposes the concrete is usually tested after 7 days and sometime 3 days in order to get a reasonably quick indication of any potential problems.

While some design methods and construction programmes may allow the designer to use a higher age strength for design, caution should be used. Relatively little research has been done on the long term strength of concrete road pavements in service and the strengths achieved will depend on the curing conditions at the particular location. In the US values for the 20 year strength of the concrete are capped at a ratio of 1.20 compared to the 28 day strength in arid areas, and 1.35 in other areas. A ratio of 1.19 is often used for 90 day strengths compared to 28 days strengths and where the construction programme allows this 90 day strength can be used for design.

The CivilWeb Concrete Strength At 7 Days Calculator tool can be used to estimate the compressive strength of concrete at any age based on any specification.

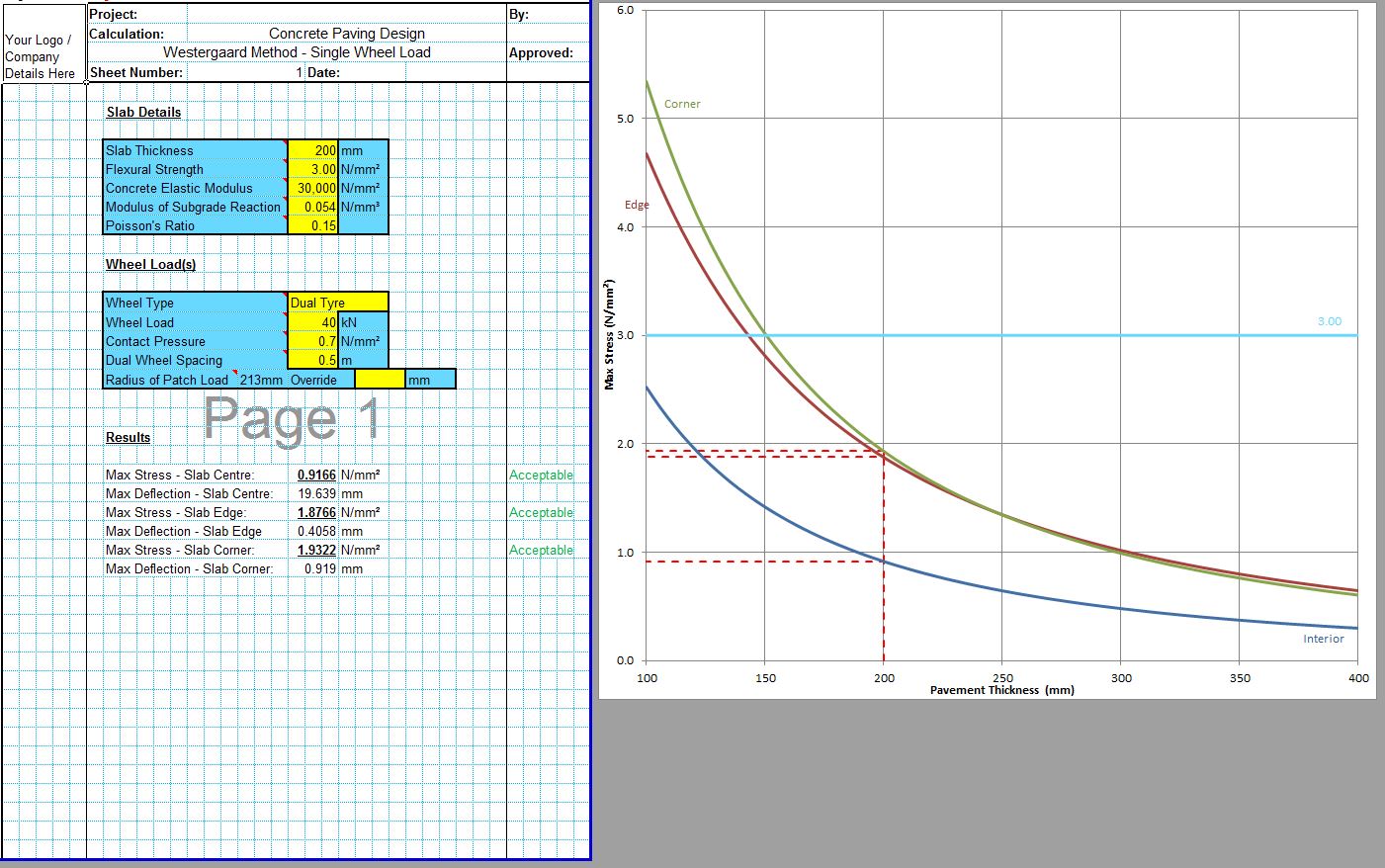

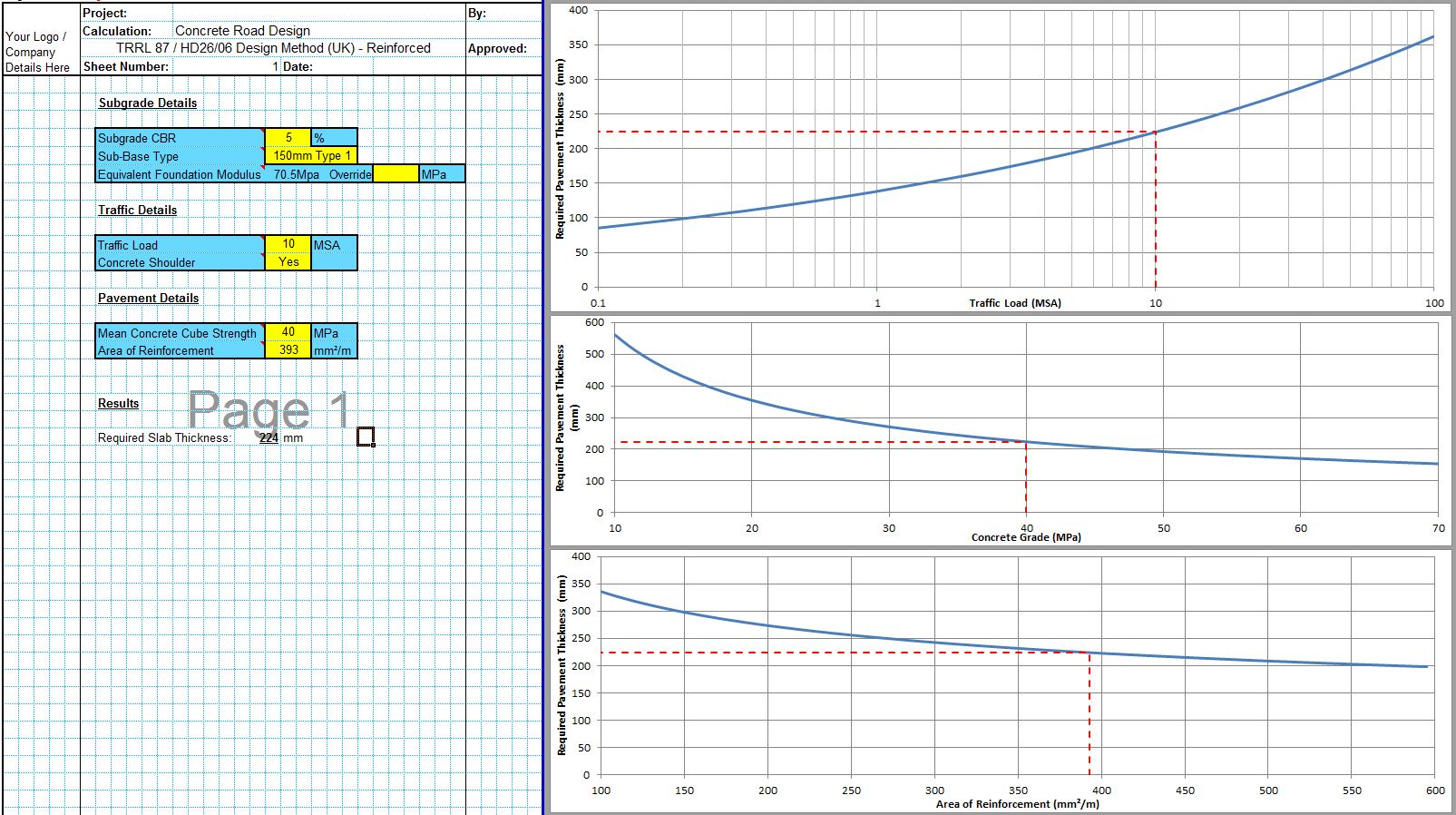

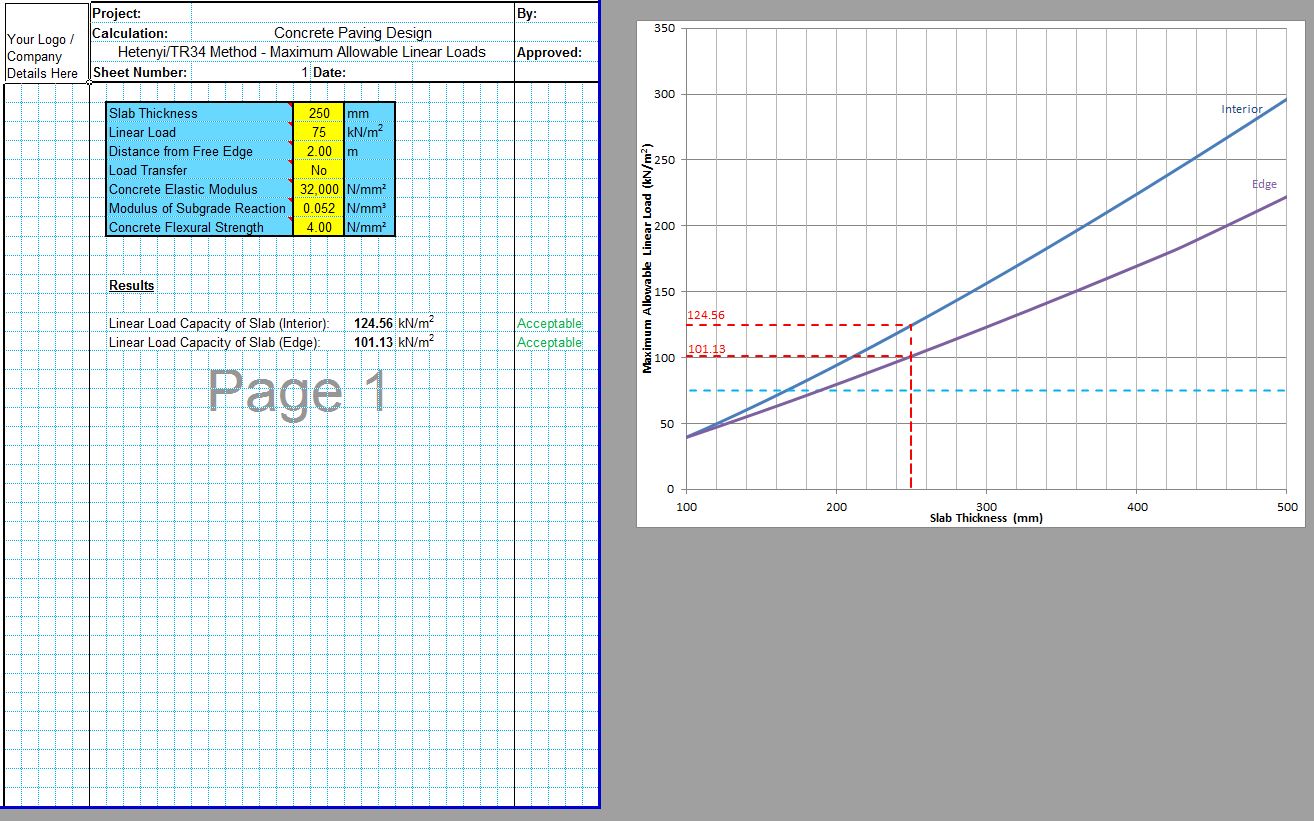

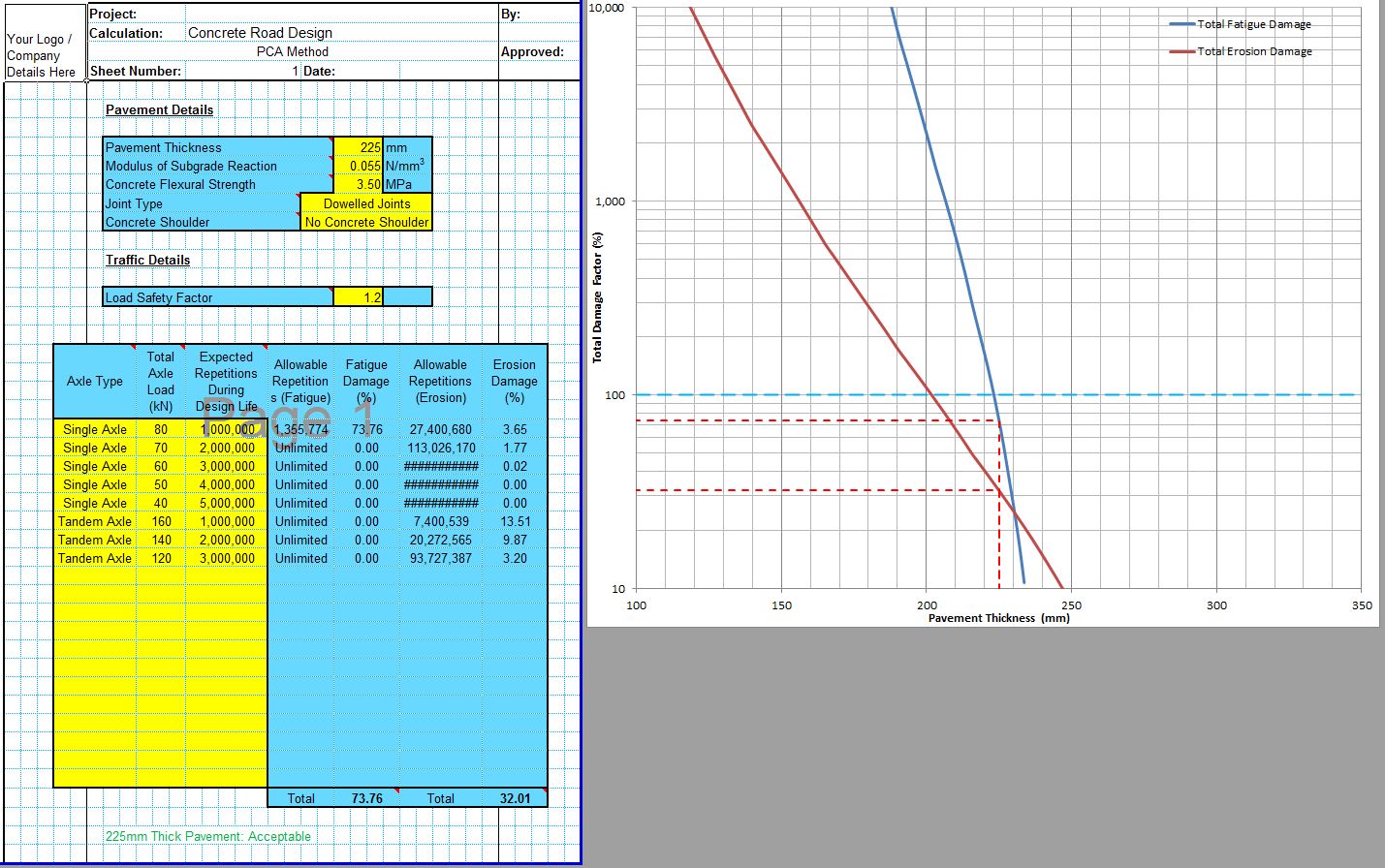

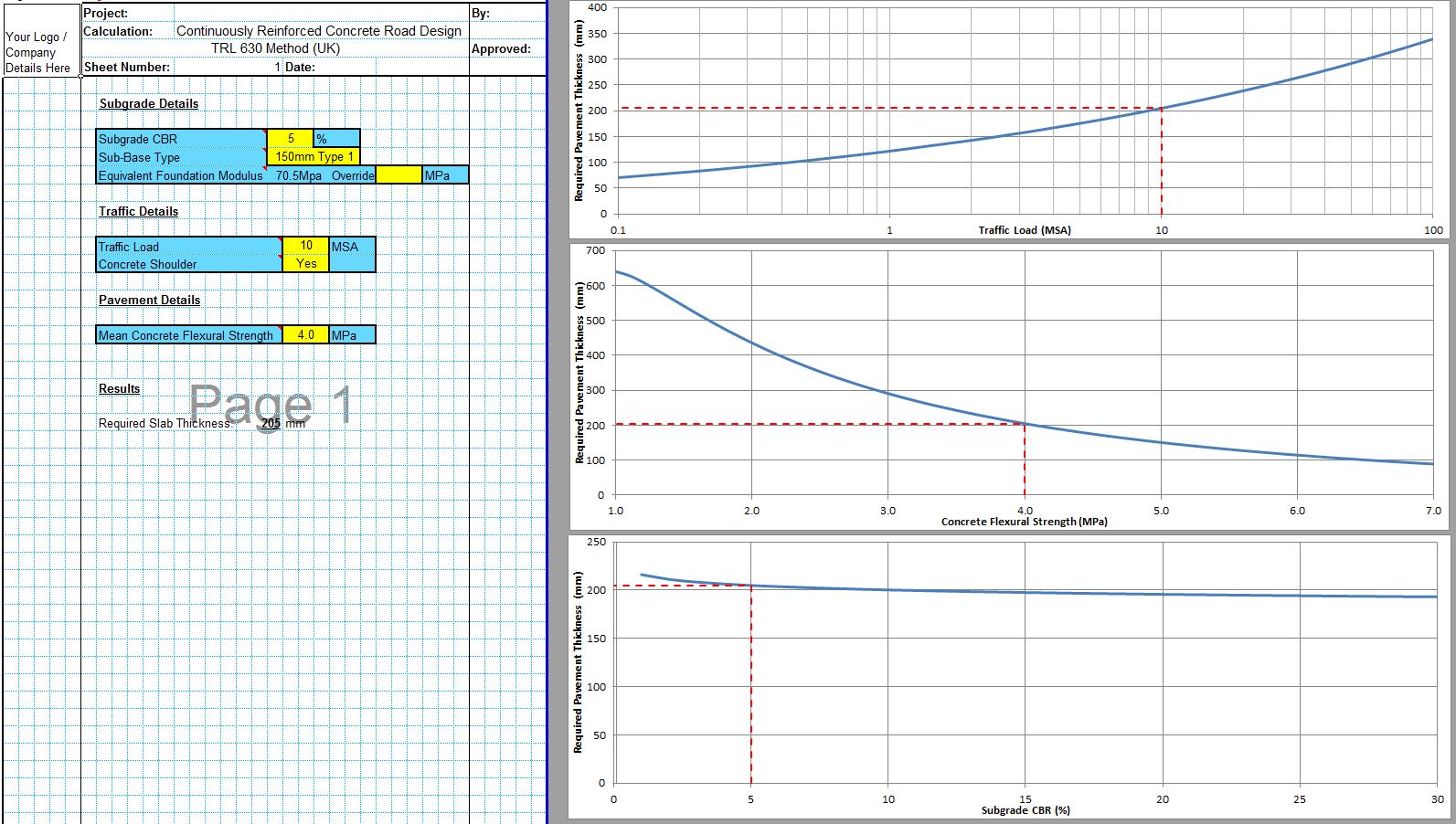

CivilWeb Rigid Pavement Design Suite

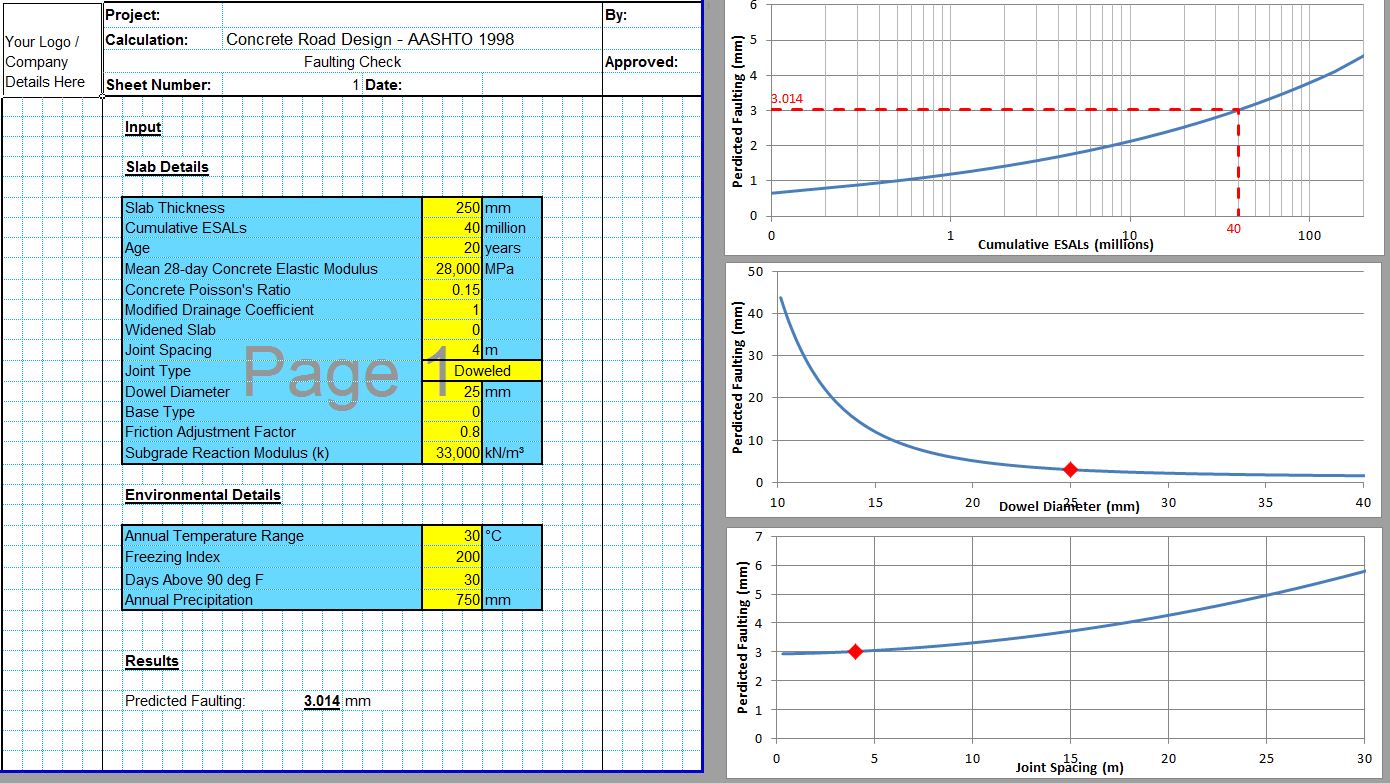

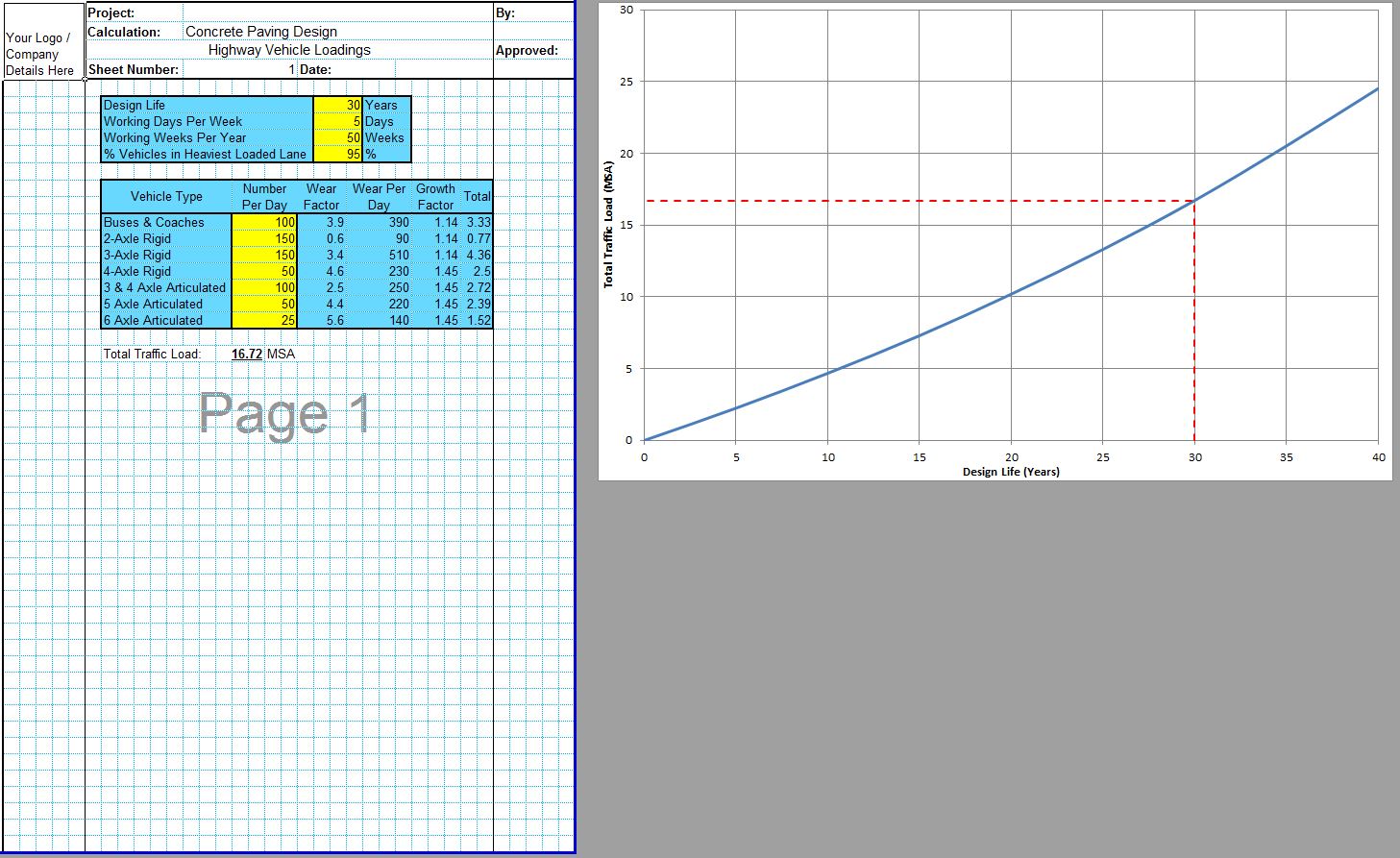

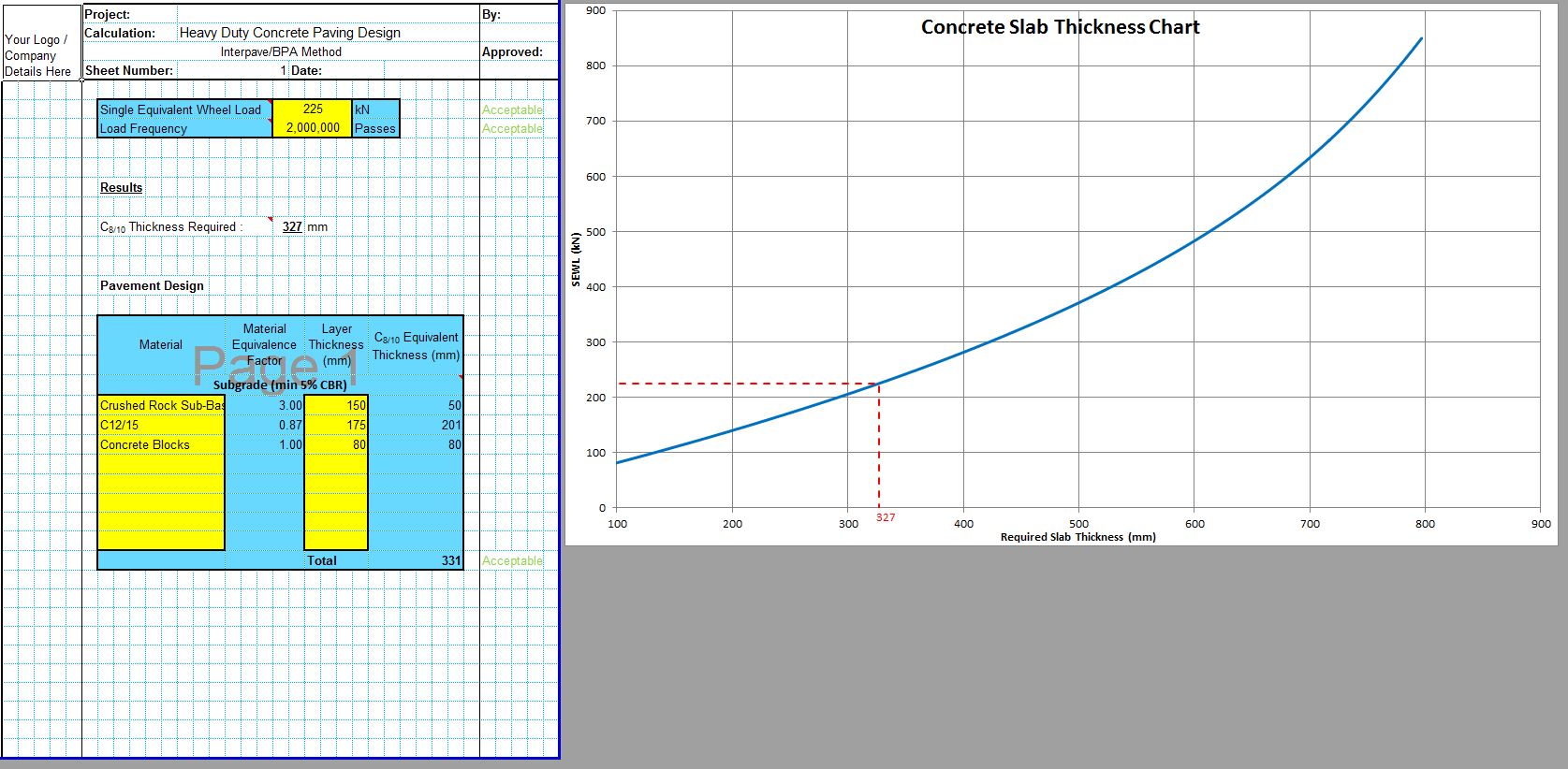

The CivilWeb Rigid Pavement Design Suite of spreadsheets includes all the concrete analysis tools mentioned on ths page. These include the conversion tool for compressive/flexural strength, a characteristic strength calculator and a concrete maturity calculator tool. Each is available for purchase individually for £5. Alternatively, all these concrete analysis tools are included with the CivilWeb Rigid Pavement Design Suite which is available for only £20 and includes full concrete road design spreadsheets.